Self-adhesive arc-resistant, fire-resistant and flame-retardant adhesive tape and preparation method thereof

A fire-retardant, arc-resistant technology, applied in the direction of adhesives, adhesive types, chloroprene adhesives, etc., can solve the problems of ineffective protection of internal wires and cables, single function of fire-retardant and flame-retardant tapes, and achieve functional Complementary, excellent water resistance, the effect of enhancing fire resistance and flame retardant properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

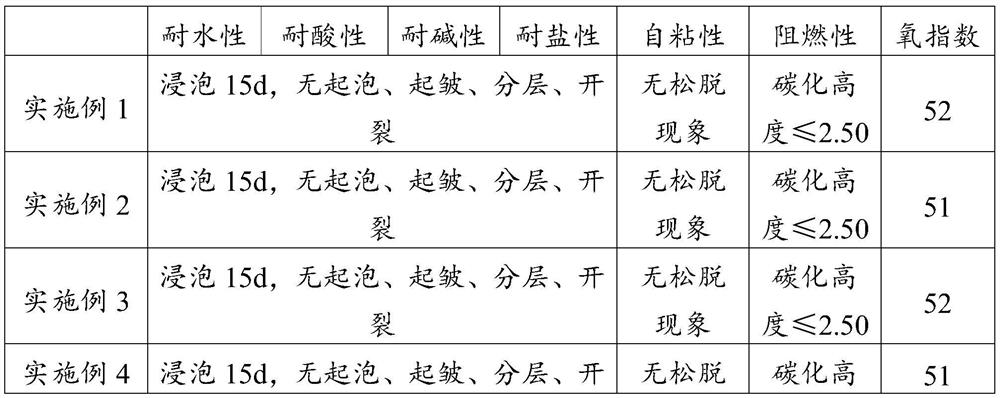

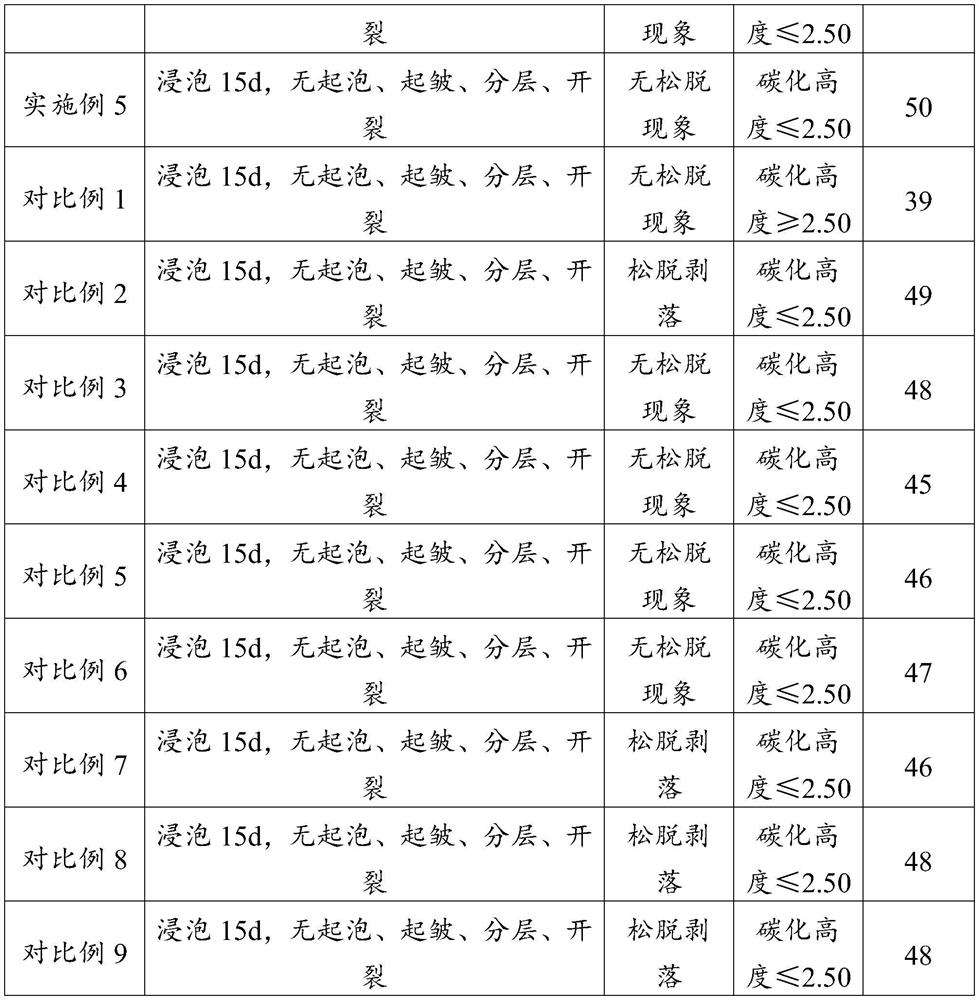

Examples

Embodiment 1

[0047] A self-adhesive arc-resistant, fire-resistant and flame-retardant adhesive tape, comprising the following raw material components in parts by weight: 40 parts of chlorinated polyethylene resin, 30 parts of neoprene rubber, 30 parts of nitrile rubber, 40 parts of aluminum hydroxide, modified 5 parts of aluminum hydroxide, 30 parts of ammonium polyphosphate, 10 parts of antimony trioxide, 10 parts of plasticizer TPP, 5 parts of rosin resin, 1 part of antioxidant 1010, 0.5 parts of sulfur, 8.5 parts of carbon black.

[0048] The method for the self-adhesive arc-resistant, fire-resistant and flame-retardant adhesive tape comprises the steps:

[0049] Weighing: Weigh each raw material component according to the above ratio;

[0050] The first mixing: Put neoprene, nitrile rubber and polyvinyl chloride resin into the internal mixer and mix evenly, then add anti-aging agent 1010, carbon black, aluminum hydroxide, modified aluminum hydroxide, ammonium polyphosphate, Put antimo...

Embodiment 2

[0054] A self-adhesive arc-resistant, fire-resistant and flame-retardant adhesive tape, comprising the following raw material components in parts by weight: 20 parts of chlorinated polyethylene resin, 10 parts of neoprene rubber, 15 parts of nitrile rubber, 40 parts of aluminum hydroxide, 15 parts of magnesium, 30 parts of decabromodiphenyl ether, 10 parts of antimony trioxide, 0 parts of plasticizer DOA, 5 parts of C5 petroleum resin, 1 part of antioxidant RD, 0.5 parts of sulfur, 2.5 parts of DCP, 5 parts of carbon black 3 parts, white carbon black 3 parts.

[0055] The method for the self-adhesive arc-resistant, fire-resistant and flame-retardant adhesive tape comprises the steps:

[0056] Weighing: Weigh each raw material component according to the above ratio;

[0057] The first mixing: put neoprene, nitrile rubber polyvinyl chloride resin into the internal mixer and mix evenly, then add anti-aging agent RD, carbon black, white carbon black, aluminum hydroxide, magnesium...

Embodiment 3

[0061] A self-adhesive arc-resistant, fire-resistant and flame-retardant adhesive tape, comprising the following raw material components in parts by weight: 20 parts of chlorinated polyethylene resin, 10 parts of neoprene rubber, 10 parts of nitrile rubber, 10 parts of aluminum hydroxide, modified 5 parts of aluminum hydroxide, 10 parts of melamine cyanurate, 5 parts of antimony trioxide, 0 parts of plasticizer TPP, 2 parts of rosin resin, 10 parts of anti-aging agent, 0 parts of sulfur, and 5 parts of carbon black.

[0062] The method for the self-adhesive arc-resistant, fire-resistant and flame-retardant adhesive tape comprises the steps:

[0063] Weighing: Weigh each raw material component according to the above ratio;

[0064] The first mixing: Put neoprene, nitrile rubber and polyvinyl chloride resin into the internal mixer and mix evenly, then add anti-aging agent 1010, carbon black, aluminum hydroxide, modified aluminum hydroxide, ammonium polyphosphate, Put antimony t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com