A kind of heat-sensitive type film-forming resin for exempting CTP plate and preparation method thereof

A film-forming resin and treatment-free technology, applied in the field of materials, can solve the problems of poor heat resistance, affecting the quality of offset printing CTP plates, limiting the development of offset printing CTP plates, etc., to achieve the effect of increasing melting point, weakening thermal motion, and small weight loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Present embodiment is a kind of modifying agent, and the preparation method of described modifying agent comprises the following steps:

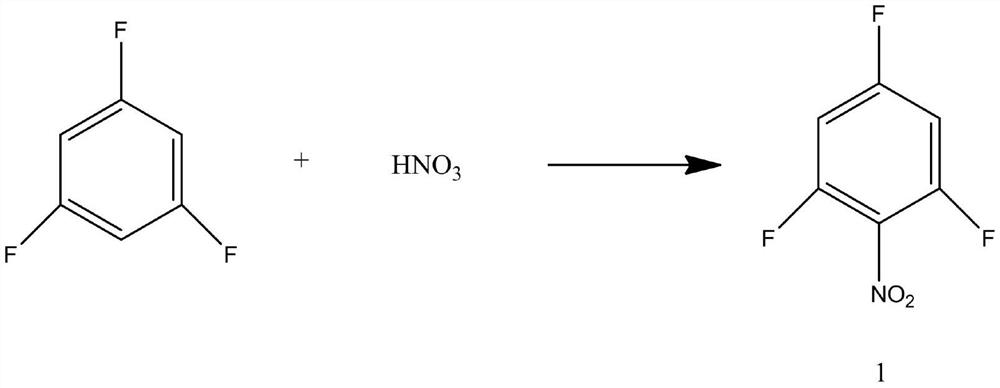

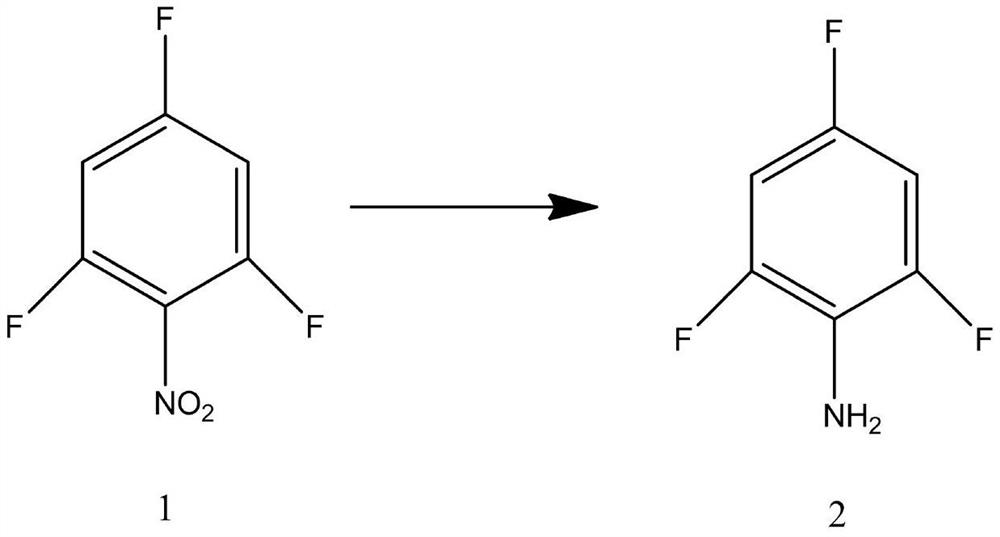

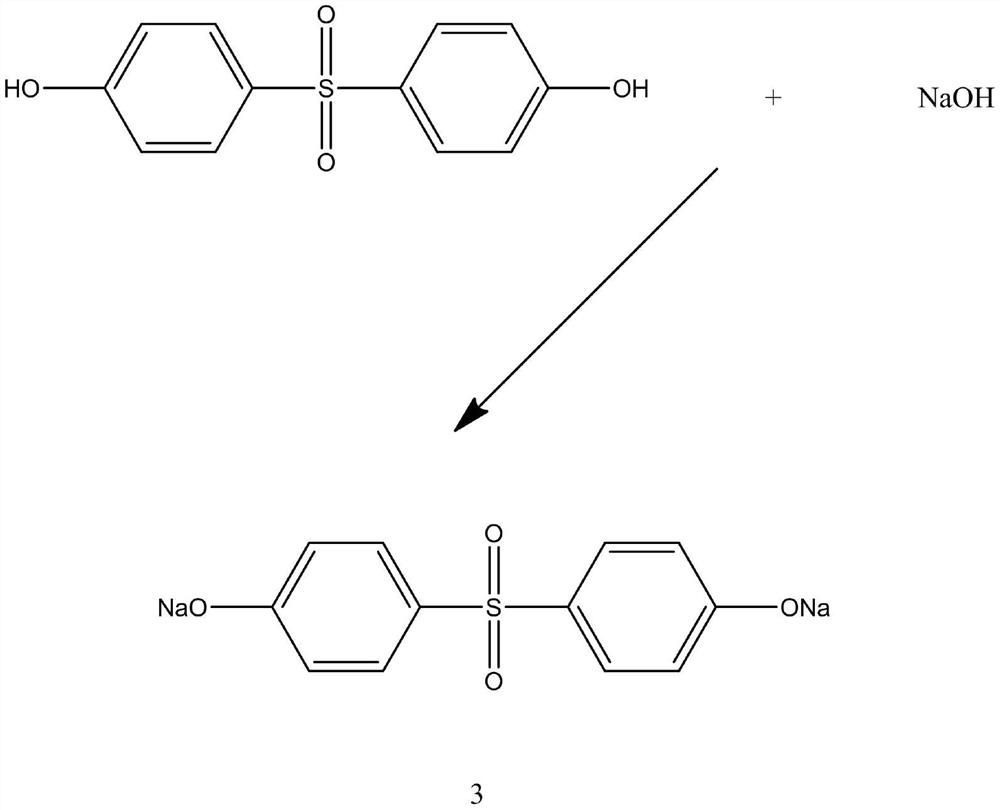

[0044]S1: Add the mixed acid into a three-necked flask equipped with a stirrer, a thermometer and a constant pressure dropping funnel, add 1,3,5-trifluorobenzene into the constant pressure dropping funnel, and stir at a temperature of 60°C Add 1,3,5-trifluorobenzene dropwise into the three-necked flask at a speed of 100r / min, and control the dropping rate at 1 drop / s. After the dropwise addition, raise the temperature to 68°C and continue stirring at a constant temperature for 2h After the reaction, the reaction product was washed 3 times successively with deionized water, sodium hydroxide solution and deionized water, and suction filtered to obtain intermediate 1; the mixed acid was controlled to be 65% concentrated nitric acid and mass fraction The concentrated sulfuric acid that fraction is 98% is according to the mixture that volu...

Embodiment 2

[0050] Present embodiment is a kind of modifying agent, and the preparation method of described modifying agent comprises the following steps:

[0051] S1: Add the mixed acid into a three-necked flask equipped with a stirrer, a thermometer and a constant pressure dropping funnel, add 1,3,5-trifluorobenzene into the constant pressure dropping funnel, and stir at a temperature of 62°C. Add 1,3,5-trifluorobenzene dropwise into the three-necked flask at a speed of 150r / min, and control the dropping rate at 1 drop / s. After the dropwise addition, raise the temperature to 70°C and continue the constant temperature stirring reaction for 2.5 h, after the reaction finishes, the reaction product is washed 4 times successively with deionized water, sodium hydroxide solution, and deionized water, and suction filtered to obtain intermediate 1; the mixed acid is controlled to be concentrated nitric acid with a mass fraction of 65% and The concentrated sulfuric acid that mass fraction is 98% ...

Embodiment 3

[0057] Present embodiment is a kind of modifying agent, and the preparation method of described modifying agent comprises the following steps:

[0058] S1: Add the mixed acid into a three-necked flask equipped with a stirrer, a thermometer and a constant pressure dropping funnel, add 1,3,5-trifluorobenzene into the constant pressure dropping funnel, and stir at a temperature of 65°C Add 1,3,5-trifluorobenzene dropwise into the three-necked flask at a speed of 200r / min, and control the dropping rate at 1 drop / s. After the dropwise addition, raise the temperature to 72°C and continue stirring at a constant temperature for 3h After the reaction, the reaction product was washed 5 times successively with deionized water, sodium hydroxide solution, and deionized water, and suction filtered to obtain intermediate 1; the mixed acid was controlled to be 65% concentrated nitric acid and mass fraction The concentrated sulfuric acid that fraction is 98% is according to the mixture that vo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com