Glass wool for building and partition plate containing glass wool

A glass wool and surface treatment technology, applied in the field of glass wool for construction and separators containing the glass wool, can solve the problems of limited doping amount and limited research and development of composite materials, so as to improve anti-aging and increase load capacity. , Improve the effect of aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~ Embodiment 5

[0036] Embodiment 1~embodiment 5 provides a kind of glass wool surface treatment method, concrete operation is as follows:

[0037] Step S1: The ultra-fine glass wool raw material is impregnated with acid first, and then cleaned to obtain acid-impregnated glass wool. The acid used is 40%wt HF.

[0038] Step S2: Nano-TiO 2 Dispersed in ethanol solution, nano-TiO 2 Ultrasonic dispersion in ethanol solution to obtain 15%wt nano-TiO 2 Dispersions.

[0039] Step S3: impregnating acid-leached glass wool in nano-TiO 2 After drying in the dispersion, repeat the operation to obtain pretreated glass wool;

[0040] Step S4: impregnating the pretreated glass wool with 2%wt silane coupling agent solvent, and drying to obtain modified glass wool.

[0041] The specific reaction parameters of steps S1 to S4 are shown in Table 1.

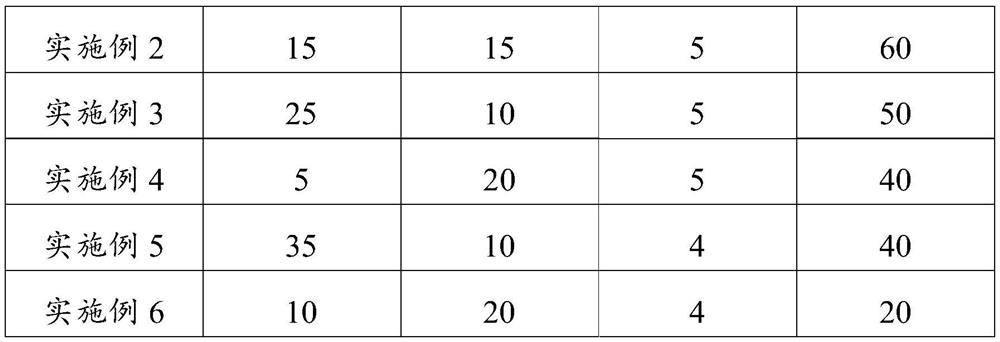

[0042] Table 1 embodiment 1~embodiment 6 specific reaction conditions

[0043]

[0044]

Embodiment 7

[0046] The present embodiment provides a kind of glass wool surface treatment method, concrete operation is as follows:

[0047] Step S1: the ultrafine glass wool raw material is impregnated with acid first, and then cleaned to obtain acid-impregnated glass wool. The acid used is 40%wt HF, and the impregnation time is 10 minutes.

[0048] Step S2: Nano-TiO 2 Dispersed in ethanol solution, nano-TiO 2 Ultrasonic dispersion in ethanol solution to obtain 15%wt nano-TiO 2 Dispersions.

[0049] Step S3: impregnating acid-leached glass wool in nano-TiO 2 After the dispersion was dried for 20 minutes, pretreated glass wool was obtained;

[0050] Step S4: impregnating the pretreated glass wool with 2%wt silane coupling agent solvent for 40min, and drying to obtain the modified glass wool.

Embodiment 8~ Embodiment 14

[0052] This embodiment provides a noise reduction panel for buildings, including:

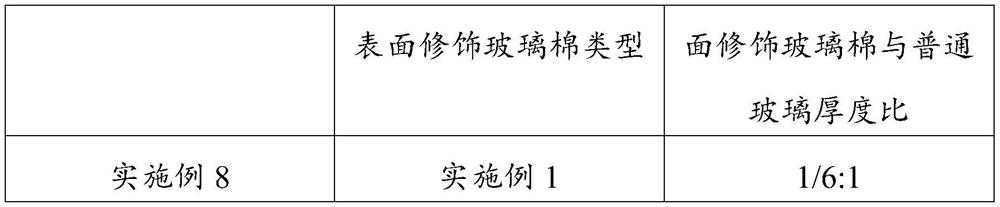

[0053] The surface-treated glass wool and ordinary glass wool are bonded with epoxy resin adhesive. Among them, the selected surface-modified glass wool types and the thickness of ordinary glass wool are shown in Table 2.

[0054] The surface modification glass wool type of table 2 embodiment 8~embodiment 14, the thickness ratio of surface modification glass wool and common glass wool

[0055]

[0056]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com