Tandem type jigger system capable of improving sorting efficiency of household garbage incinerator slag

A technology for domestic waste incineration and jigging machine, applied in the field of jigging machine, can solve problems such as affecting the working efficiency of equipment, complicated structure of shaking table, inconvenient operation, etc., so as to improve the efficiency of sorting, improve sorting efficiency, Beneficial effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

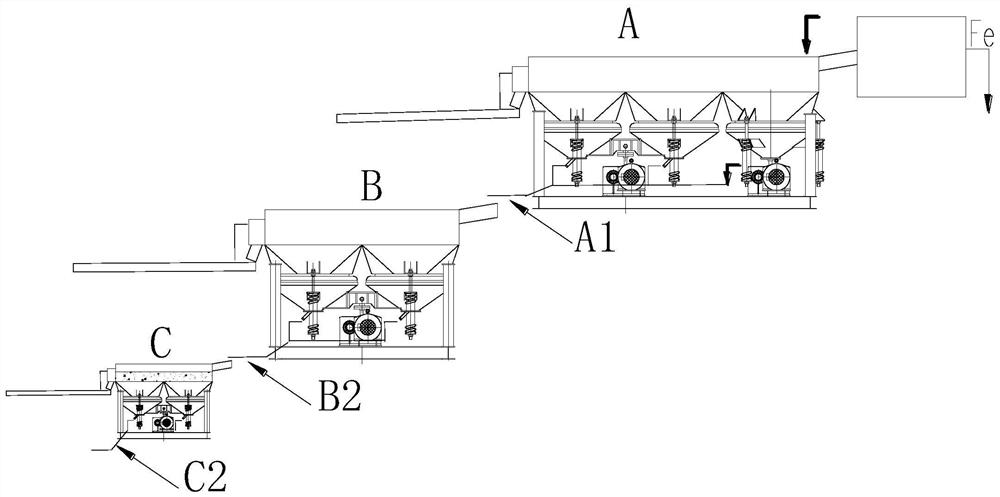

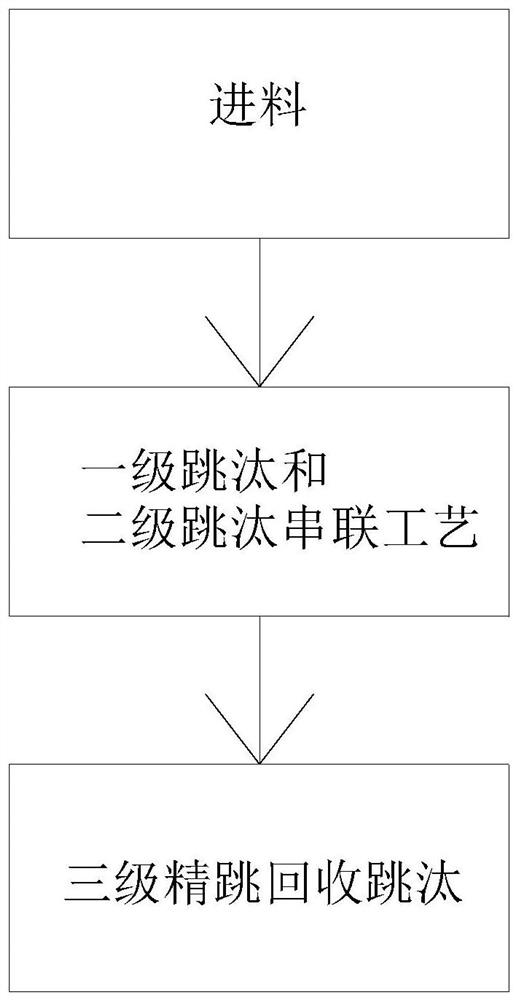

[0030] Such as Figure 1-3 As shown, the present invention provides a tandem jig system improving the efficiency of domestic waste incineration slag sorting. The series jigger system improving the efficiency of domestic waste incinerator slag sorting comprises the following steps:

[0031] Step 1, feeding materials to the series jig system;

[0032] Step 2, performing a series process of first-stage jigging A and second-stage jigging B on the feed;

[0033] Step 3: Carry out three-stage fine jump recovery jigging.

Embodiment 2

[0035] Such as Figure 1-3 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: Preferably, step 2 also includes the following steps: the sawtooth wave waveform first rises in a straight line, then falls sharply, rises again, and then falls steeply, so Repeatedly, and then use water as the beneficiation medium, sort according to the specific gravity (density) difference between the useful minerals and the gangue, discharge the slag from the side plate of the first jigging A, and discharge the first-grade concentrate at the bottom of the first jigging A Ore discharge A1, the first-level concentrated ore discharge A1 enters the top of the second-level jigger B, and cooperates with the second-level jigger to operate and sort, so that the side plate of the second-level jigger B performs slag discharge, and then the second The bottom of the second jigging B carries out secondary concentrate discharge B1.

Embodiment 3

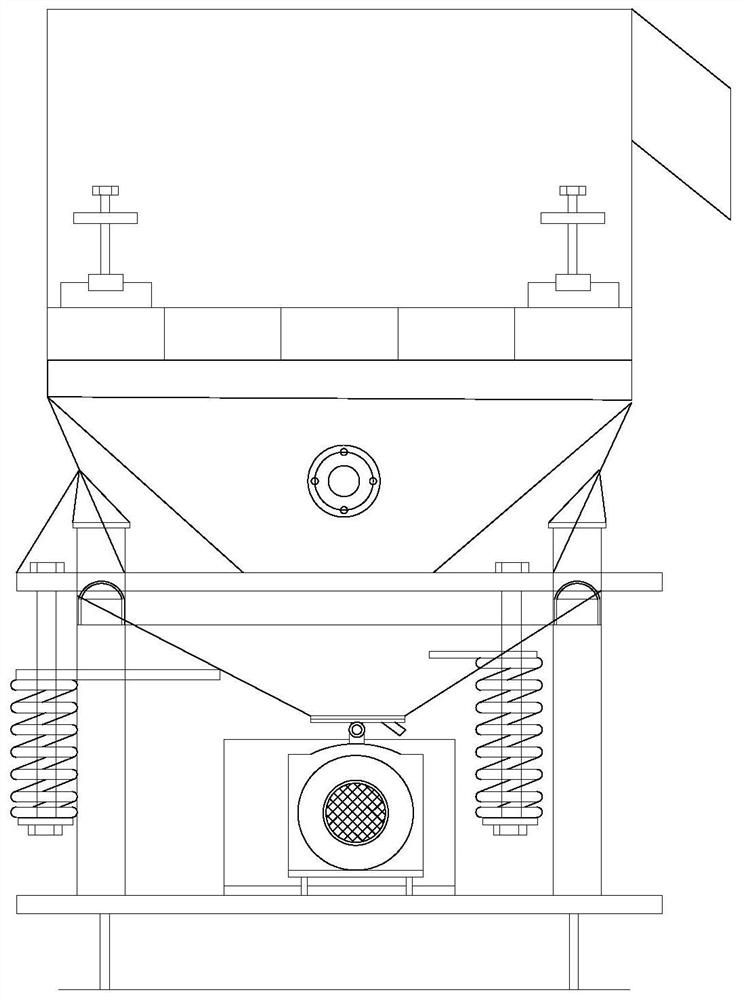

[0037] Such as Figure 1-3 Shown, on the basis of embodiment 1, the present invention provides a kind of technical scheme: preferably, in step 3, also include the following steps: adopt two special-purpose drum jigs of one square cascaded into two squares, carry out The sieve hole is optimized for three-stage fine jumping recovery jig C, and a special iron ore cushion is laid on the sieve surface, and the tailings are directly discharged into the closed-loop beneficiation. The top pressure drives the spring to press down, and then goes up through the reset of the spring, and cooperates with the resilience of the flexible connection tympanic membrane to sort the ore inside the tympanic chamber, the tailings are directly discharged into the closed-loop mineral processing, and the concentrate is separated through the three-stage sand settling water bucket The final water is directly discharged, and the concentrate in the sedimentation bucket is directly recovered from copper sand...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com