Making process of rice noodles

A production process and rice noodle technology, which is applied in food processing, the function of food ingredients, food ingredients as antioxidants, etc., can solve the problems of high starch content, paste soup, etc., and achieve the effect of rich nutrition, improved quality, and smooth taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

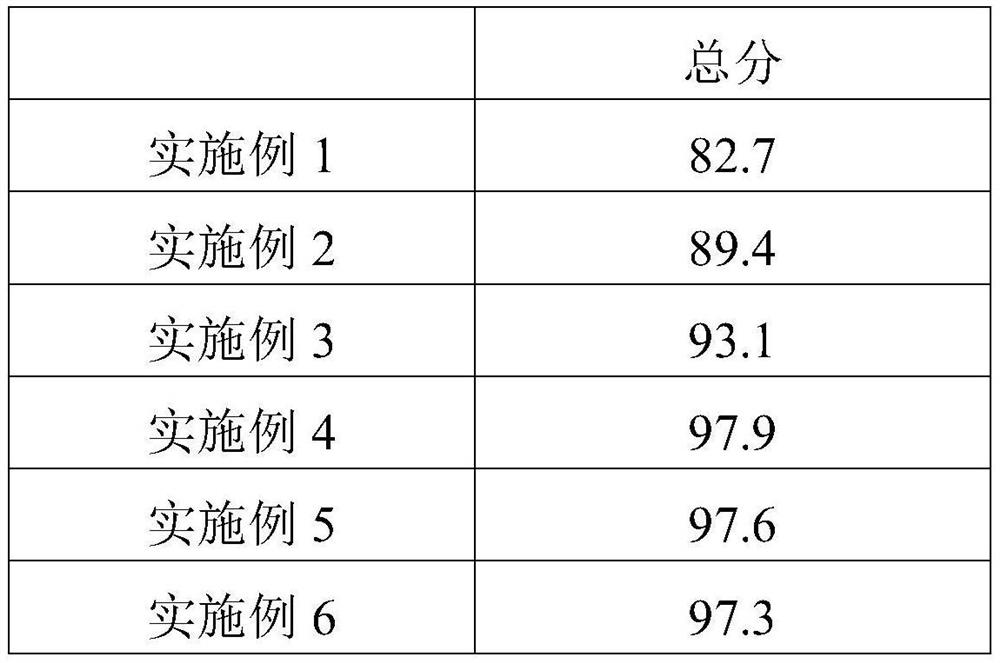

Embodiment 1

[0040] The manufacturing process of rice noodles comprises the following steps:

[0041] (1) rice is soaked, cleaned and filtered, and the cleaned rice is added into water to be ground together, passed through a 40-mesh sieve to obtain a rice slurry, and the mass ratio of the rice to water is 1:4;

[0042] (2) Pulverize the indica rice and pass through a 400-mesh sieve to obtain indica rice powder; add the indica rice powder into water and stir evenly, wherein the mass ratio of indica rice powder to water is 1:4 to obtain indica rice slurry;

[0043] (3) Mix rice slurry and indica rice slurry evenly to obtain rice / indica rice mixture, wherein the mass ratio of rice slurry to indica rice slurry is 3:1; hydroxypropyl distarch phosphate, walnut peptide, wheat Dietary fiber and konjac glucomannan were added to the rice / indica rice mixture and stirred evenly, and placed at 35°C for 60 minutes to obtain the processed rice / indica rice mixture, wherein the mass ratio of rice / indica ri...

Embodiment 2

[0046] The manufacturing process of rice noodles comprises the following steps:

[0047] (1) rice is soaked, cleaned and filtered, and the cleaned rice is added into water to be ground together, passed through a 40-mesh sieve to obtain a rice slurry, and the mass ratio of the rice to water is 1:4;

[0048] (2) inoculate the strain into the rice slurry, the inoculum amount is 0.05wt%, and place it at 37° C. for 8 hours of fermentation to obtain the rice fermentation slurry; the strain is Lactobacillus plantarum subspecies;

[0049] (3) Pulverize the indica rice and pass through a 400-mesh sieve to obtain indica rice powder; add the indica rice powder into water and stir evenly, wherein the mass ratio of indica rice powder to water is 1:4 to obtain indica rice slurry;

[0050] (4) Mix rice fermentation slurry and indica rice slurry evenly to obtain rice / indica rice mixture, wherein the mass ratio of rice fermentation slurry to indica rice slurry is 3:1; hydroxypropyl distarch ph...

Embodiment 3

[0053] The manufacturing process of rice noodles comprises the following steps:

[0054] (1) rice is soaked, cleaned and filtered, and the cleaned rice is added into water to be ground together, passed through a 40-mesh sieve to obtain a rice slurry, and the mass ratio of the rice to water is 1:4;

[0055] (2) inoculate the strain into the rice slurry, the inoculum amount is 0.05wt%, and place it at 37° C. for 8 hours of fermentation to obtain the rice fermentation slurry; the strain is Lactobacillus plantarum subspecies;

[0056] (3) Pulverize the indica rice and pass through a 400-mesh sieve to obtain indica rice powder; add the indica rice powder into water and stir evenly, then add glutaminase and enzymolyze it at 55° C. for 60 minutes to obtain the indica rice enzymatic hydrolyzate, wherein the indica rice powder and water The mass ratio is 1:4, and the mass ratio of indica rice powder to transglutaminase is 1:0.005;

[0057] (4) Mix the rice fermentation slurry and indi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com