A device and method for continuously injecting light oil to realize cold recovery of heavy oil

A technology for light oil and heavy oil, which is applied in wellbore/well valve devices, production fluids, earthwork drilling and production, etc. It can solve problems such as high development costs, 3-7 days of time spent, and low cold recovery efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

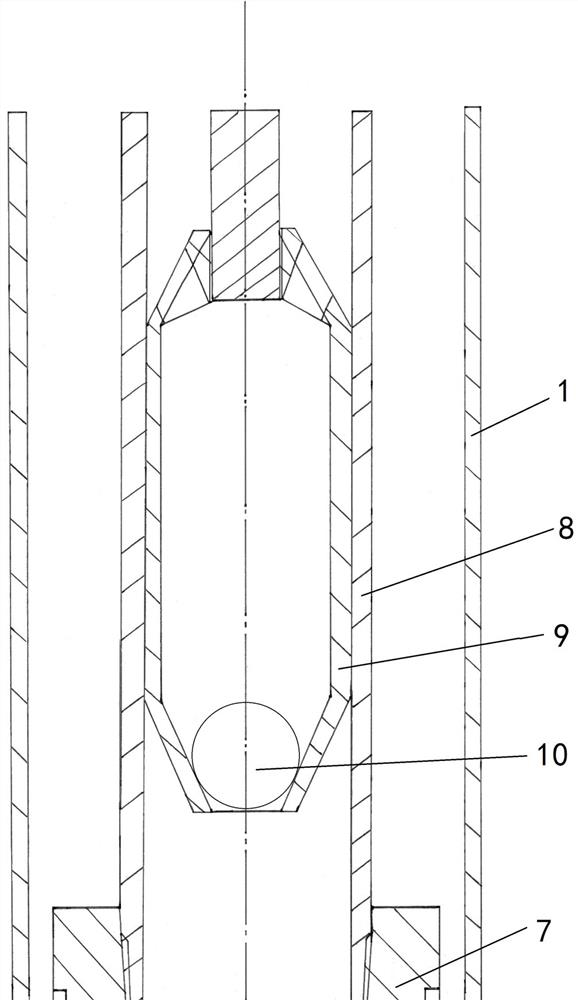

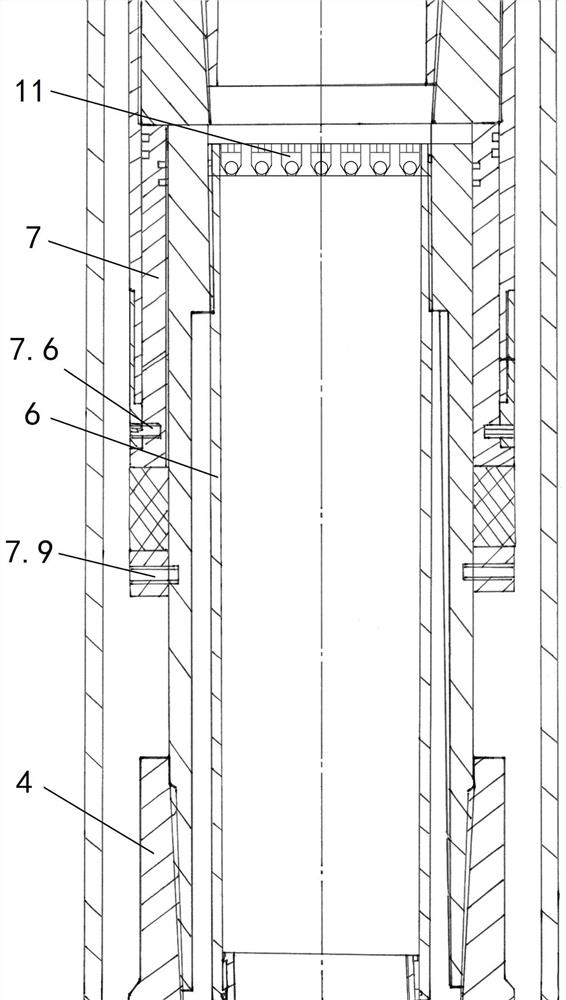

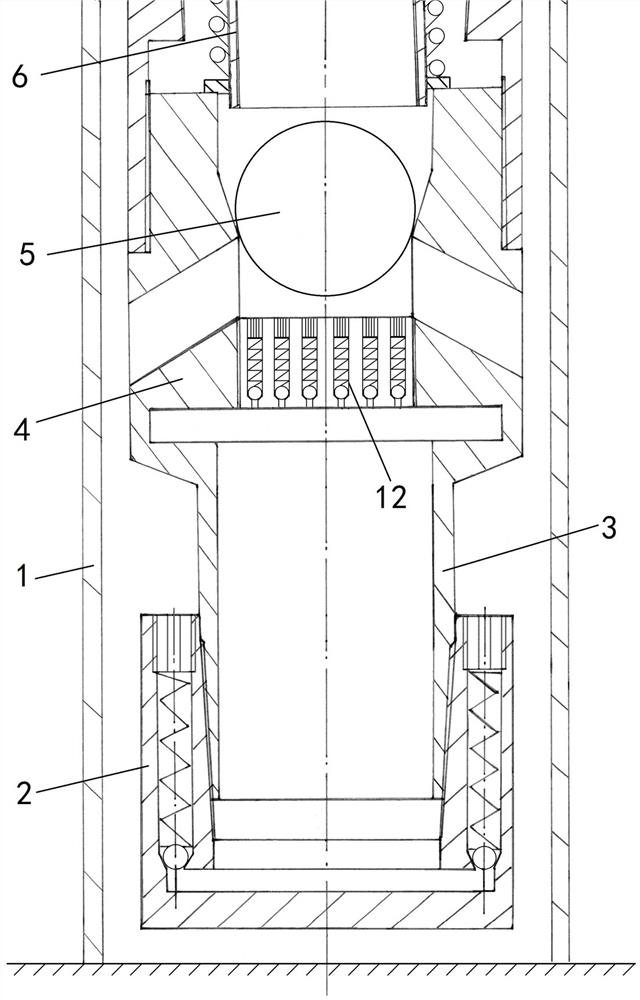

[0047] Embodiment 1, with reference to Figure 12 , a device for continuous injection of light oil to achieve cold recovery of heavy oil mentioned in the present invention, including injection diluter 2, transition pipe 3, injection suction splitter 4, suction floating ball 5, injection double-layer isolation pipe 6 , packer 7, oil well pump barrel 8, oil well pump plunger 9, plunger float 10, packer seat seal constant pressure plate 11, multifunctional constant pressure isolation plate 12, the lower end of oil well pump barrel 8 is connected to inject double Layer isolation pipe 6, a packer 7 is installed between the injection double-layer isolation pipe 6 and the casing 1, the lower end of the injection double-layer isolation pipe 6 is connected to the injection suction splitter 4, and injected into the inner double-layer isolation pipe 6 The cavity is provided with a suction floating ball 5, the lower end of the injection-suction splitter 4 is connected to the injection dil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com