A Concrete Construction Method for Rectangular Vertical Well Holes

A construction method and concrete technology, which is applied in artificial islands, water conservancy projects, infrastructure projects, etc., can solve problems such as high safety protection requirements, large material consumption, and slow construction progress, so as to achieve efficient and convenient construction and controllable quality , Construction safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

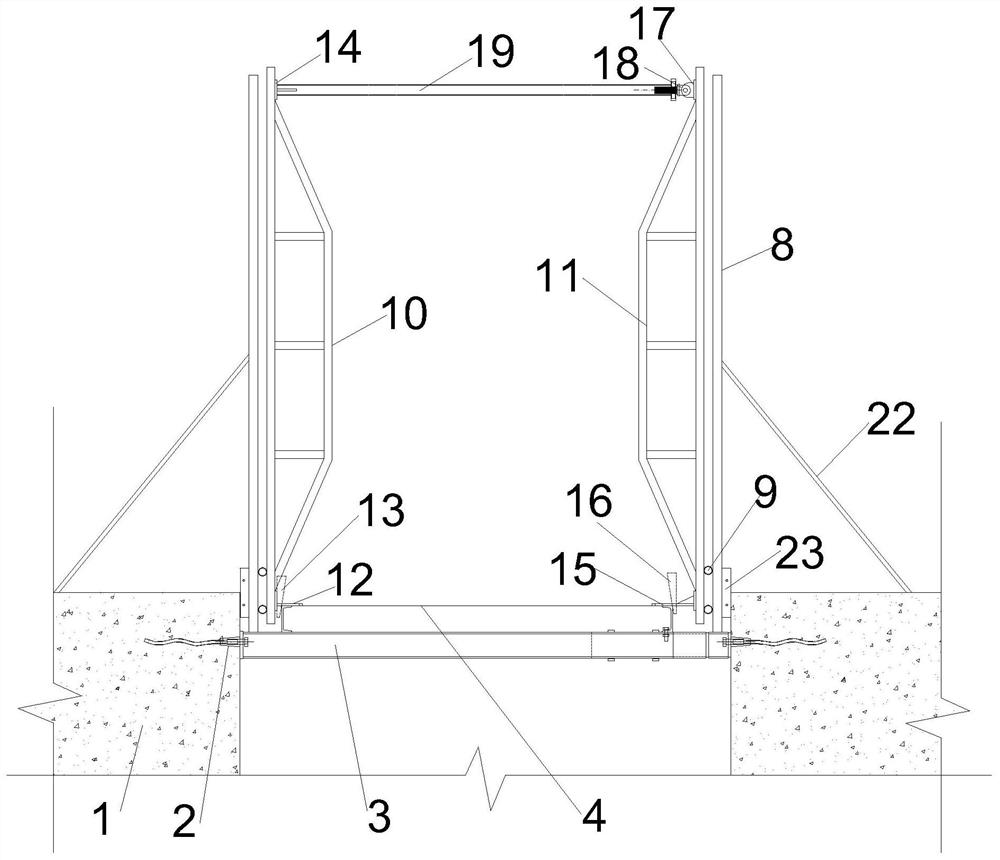

[0055] like Figure 1 to Figure 10 As shown, a concrete construction method for a rectangular vertical well hole of the present invention comprises the following steps:

[0056] Step 1, pouring the concrete foundation: according to the size of the rectangular vertical well hole, construct a concrete foundation 1 at the bottom of the shaft, and pre-embed multiple pairs of lower Doka formwork positioning cones 2 in the concrete foundation 1 along its length direction;

[0057] Step 2, hoisting the support structure: use the lifting equipment to hoist the support structure, and the support structure includes an operation platform 4 and a plurality of main beams 3 fixed on the bottom of the operation platform 4 and matched with multiple pairs of lower multi-card template positioning cones 2;

[0058] Step 3. Preliminary fixing of the bottom steel formwork: the bottom steel formwork 23 is clamped by the concrete foundation 1 and the purlin, and one side purlin along the length dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com