Preparation device and method for three-dimensional electrostatic spinning

An electrospinning and preparation device technology, applied in textiles and papermaking, fiber processing, filament/thread forming, etc., can solve problems such as difficulty in forming, inability to build three-dimensional structures, thick nanofiber materials, etc., to broaden application fields, The effect of enhancing practicality and feasibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

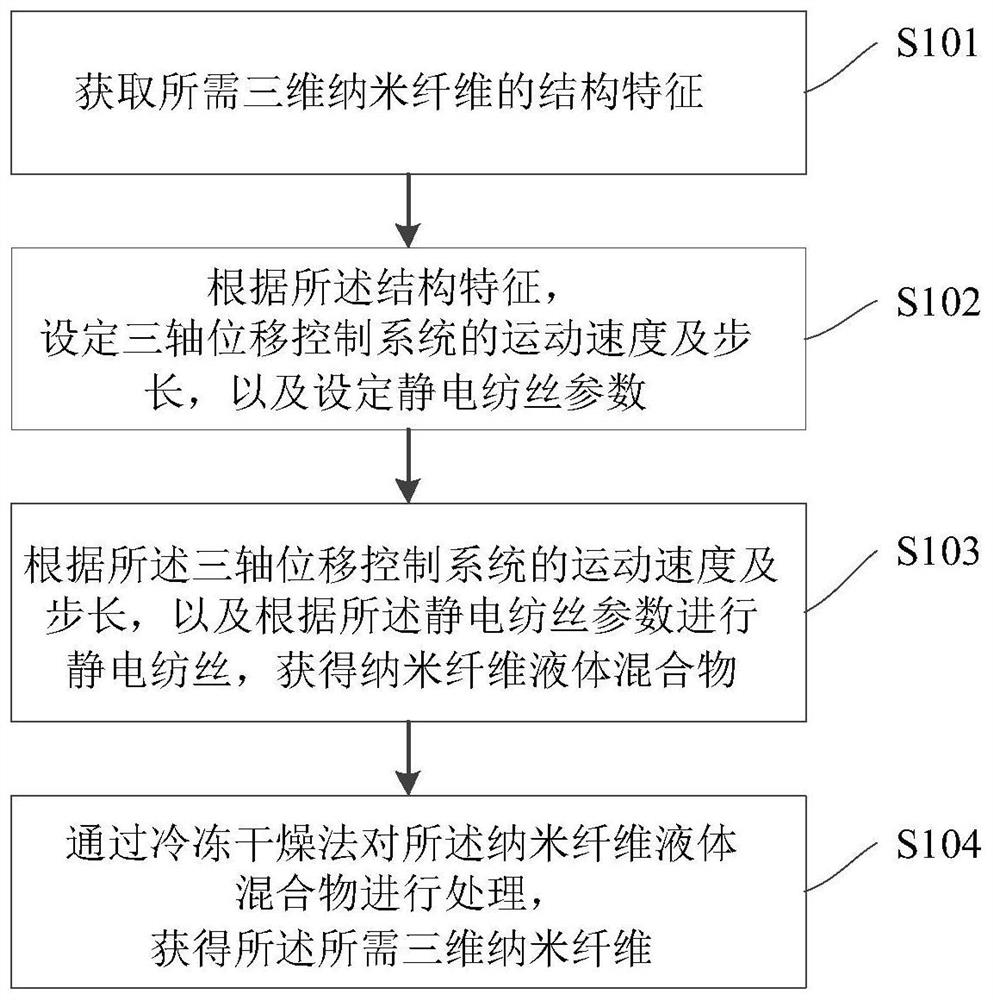

[0047] The preparation method of a kind of three-dimensional electrospinning specifically comprises:

[0048] Step S101: Acquire the structural features of the desired three-dimensional nanofibers, the structural features include the thickness of the three-dimensional nanofibers and the specific surface area of the three-dimensional nanofibers;

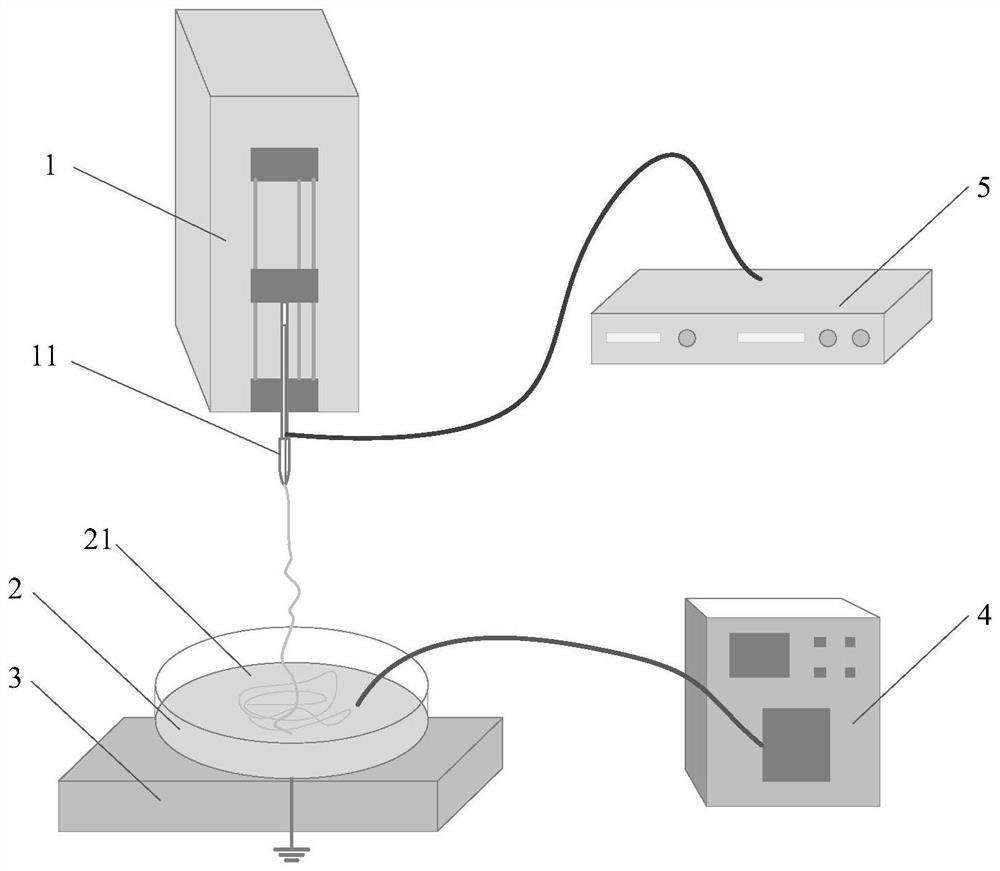

[0049] Step S102: According to the structural features, set the motion speed and step size of the three-axis displacement control system, and set the electrospinning parameters; the electrospinning parameters include: liquid inlet flow rate, spinning temperature, spinning relative Humidity, spinning time, high-voltage adjustable DC power supply voltage amplitude, vertical distance between the liquid collection device and the metal needle, the flow rate, type and temperature of the collected liquid, and the trajectory of the liquid collection device.

[0050] Specifically, since the movement speed of the three-axis displacement contr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com