Troubleshooting device, railway vehicle and control method of troubleshooting device of railway vehicle

A rail vehicle and equipment technology, applied in the field of vehicles, can solve problems such as splashing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

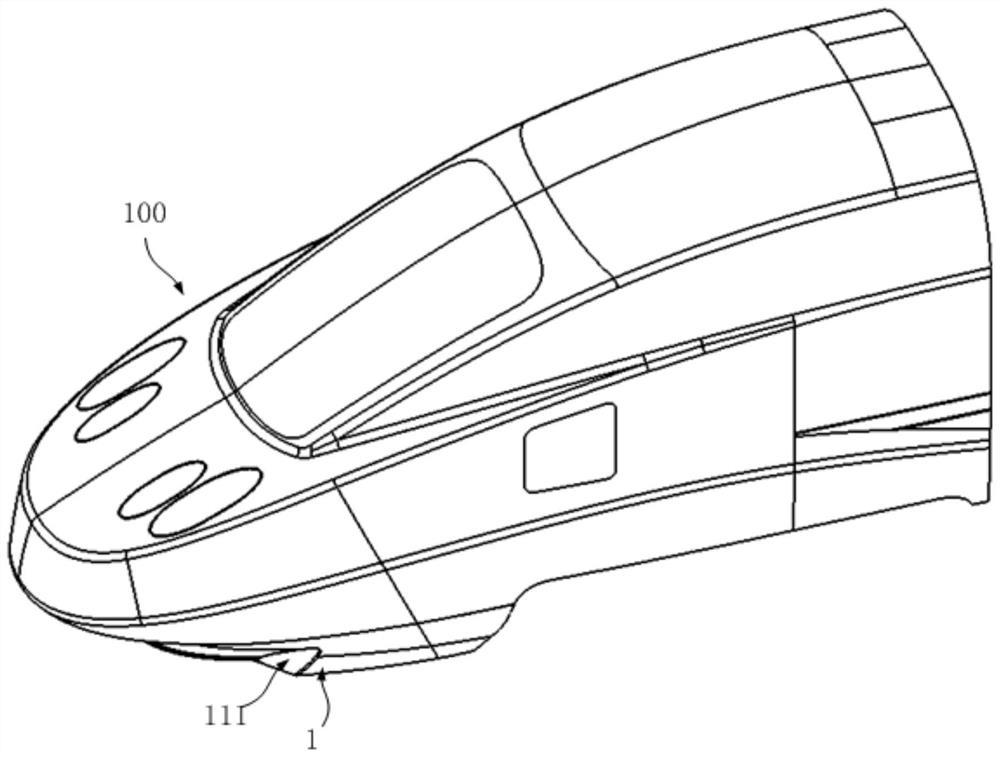

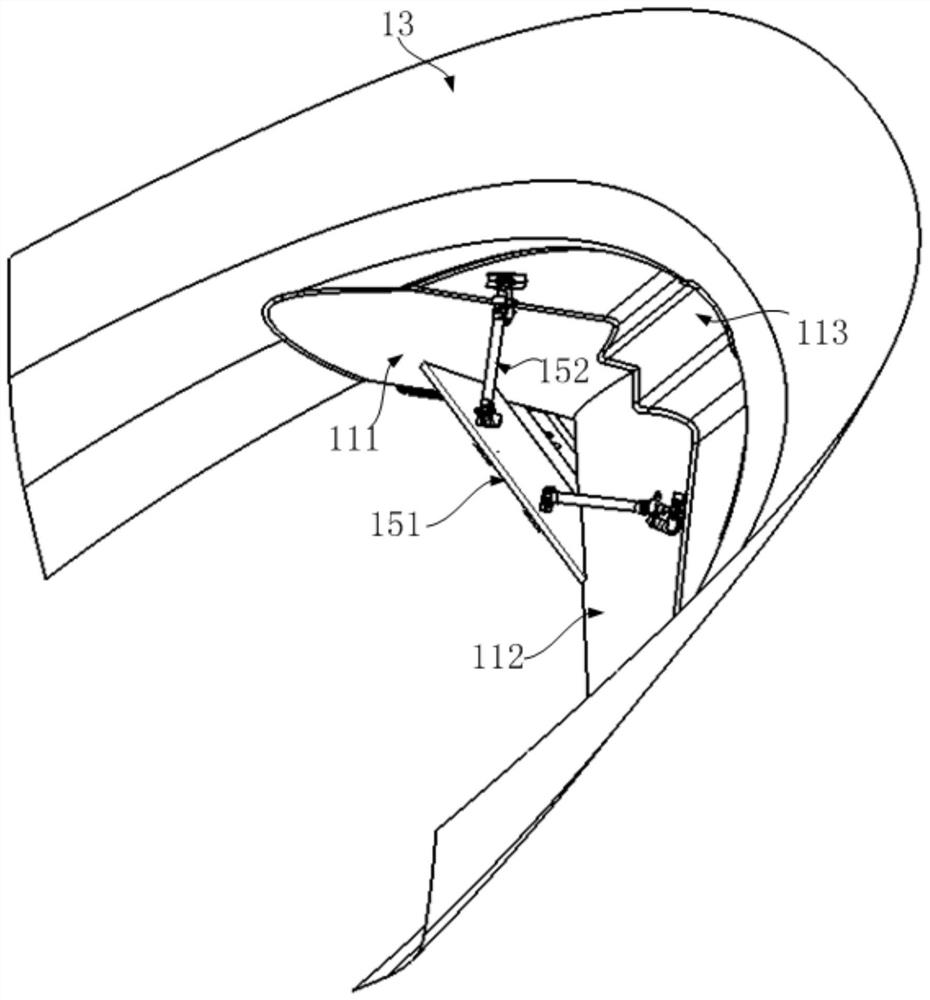

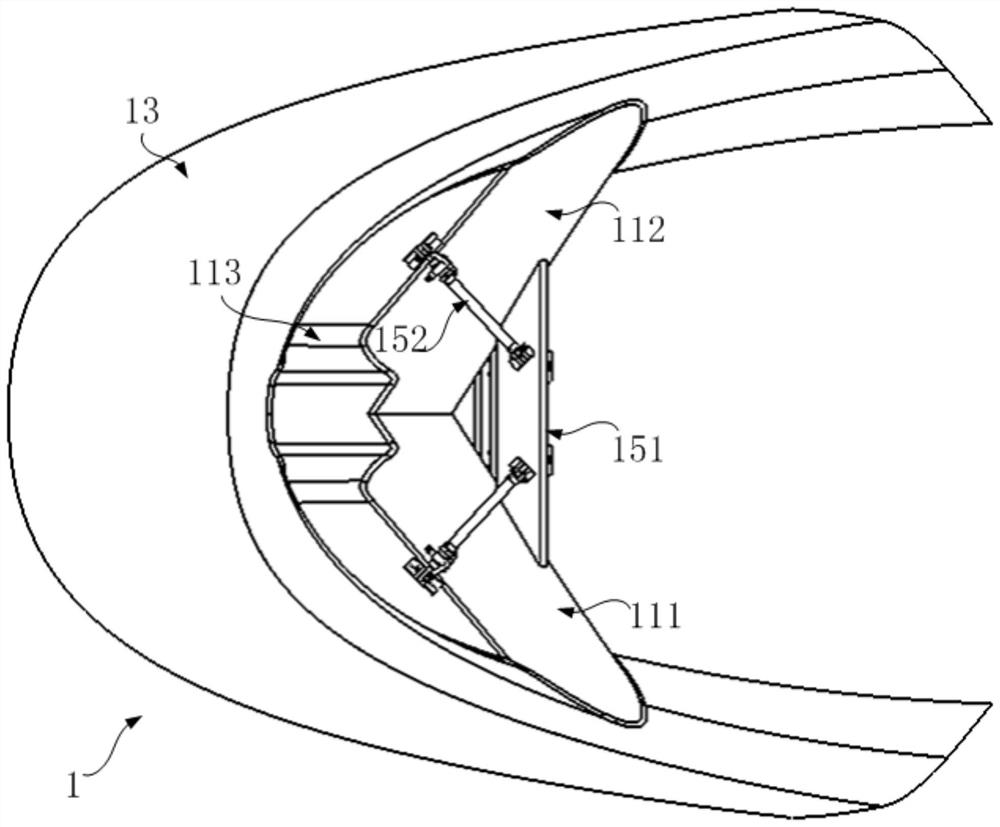

[0049] Please refer to Figure 1-5 , figure 1 It is a schematic structural diagram of the obstacle removal equipment 1 provided in Embodiment 1 of the present invention provided on a rail vehicle; figure 2 for figure 1 A schematic structural diagram of the troubleshooting device 1, showing the rear of the troubleshooting device 1; image 3 for figure 2 top view of Figure 4 for figure 1 Schematic diagram of the structure of the troubleshooting device 1, showing the front side of the troubleshooting device 1; Figure 5 for figure 2 side view.

[0050] It should be noted that, in this embodiment, "front" and "rear" are based on the forward direction of the rail vehicle, "front" is towards the forward direction, and "rear" is vice versa.

[0051] The obstacle removal device 1 in this embodiment is arranged under the front of the rail vehicle 100 for removing obstacles on the track. The troubleshooting device 1 includes a main troubleshooting board 11 for troubleshooting...

Embodiment 2

[0079] Please refer to Figure 15-20 , Figure 15 It is a schematic diagram of the troubleshooting equipment provided by Embodiment 2 of the present invention; Figure 16 for Figure 15 top view of Figure 17 for Figure 16 bottom view of Figure 18 for Figure 16 right view of Figure 19 for Figure 15 The enlarged schematic diagram of the main baffle plate in the center; Figure 20 for Figure 18 The schematic diagram of the assembly of the movable baffle plate, the first flange part and the second flange part.

[0080]The structure of embodiment 2 is basically the same as that of embodiment 1, and the same structure adopts the same reference numerals, the only difference is that in embodiment 1, the movable barrier board 12 and the first flange part 141 and the second flange part 142 are composed of The driving mechanism is driven, and the driving mechanism specifically includes the second cylinder 152 and the connecting rod 156, etc., and the driving mechanism ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com