Numerical control profile end surface milling center

A face milling and machining center technology, applied in metal processing, metal processing equipment, metal processing machinery parts, etc., can solve the problems of high labor intensity, unstable cutting accuracy, low work efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

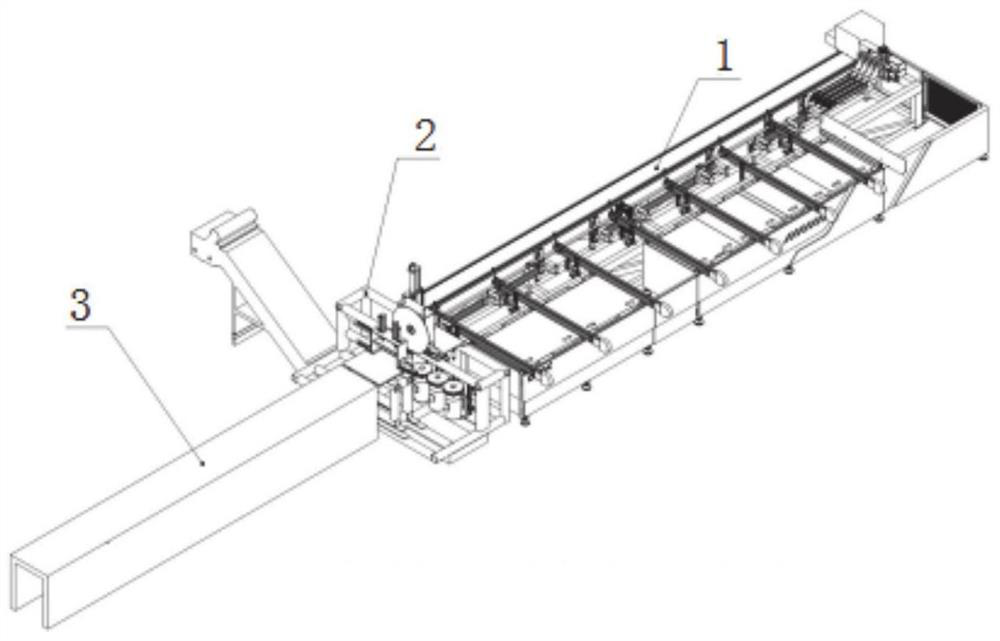

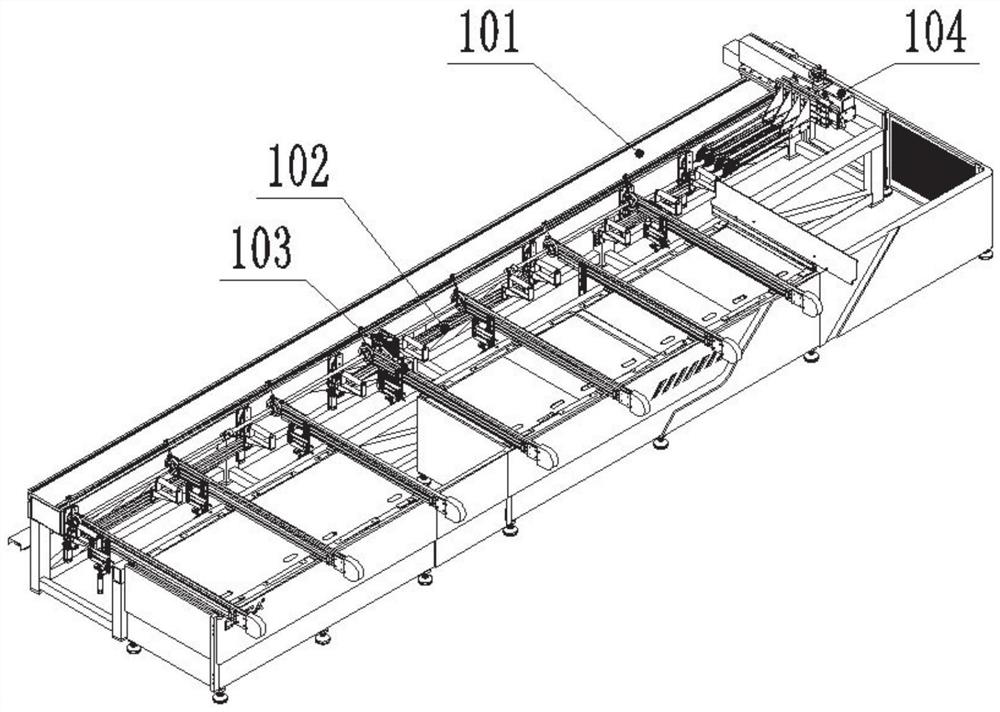

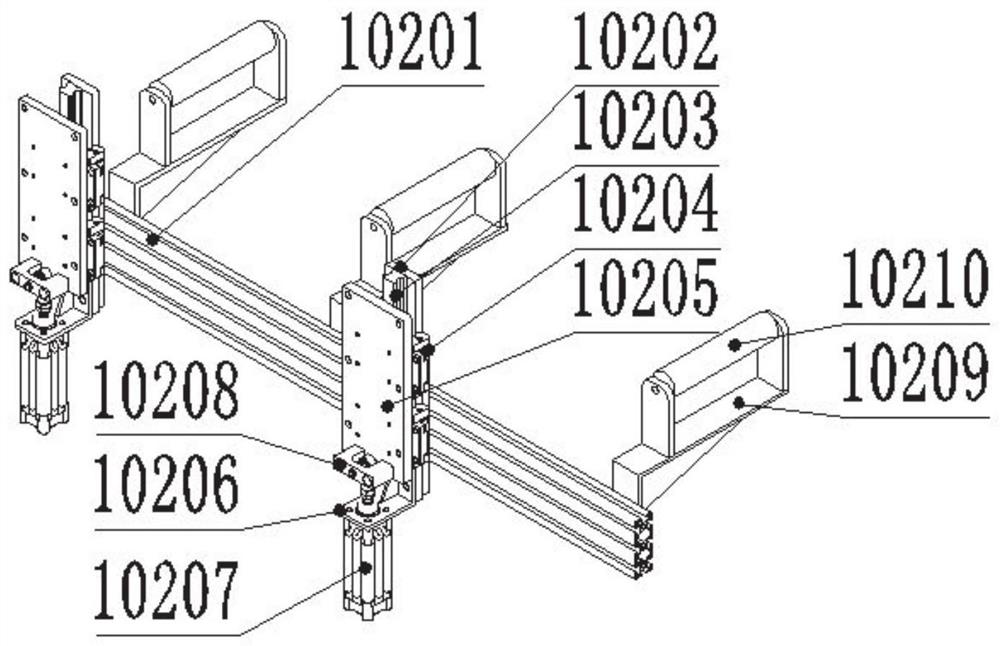

[0043] This embodiment provides a CNC profile end face milling machining center, which is suitable for profile processing, such as end face processing of aluminum alloy door and window profiles, such as figure 1 As shown, it includes a feeding section 1, a sawing section 2 and a discharging section 3 arranged in sequence, wherein the feeding section 1 includes a feeding frame 101, a lifting mechanism 102, a transmission mechanism 103, and a feeding claw mechanism 104. Through the feeding claw mechanism 104 realizes accurate feeding. The sawing section 2 includes a sawing frame 201 , a sawing part 202 , a milling part 203 , a pressing part 204 and a cutter 205 , and automatic cutting is realized through the sawing section 2 . In this embodiment, the moving direction of the profile along the feeding section 1 , the sawing section 2 and the discharging section 3 is taken as the X direction, and the transmission direction of the transmission mechanism 103 is taken as the Y directi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com