Single-wire submerged arc welding process for steel plate with thickness of 30-50mm

A welding process, submerged arc welding technology, applied in welding equipment, arc welding equipment, welding/welding/cutting items, etc., can solve the problems of more gas and labor consumption, bending deformation, and a large amount of labor, so as to improve construction efficiency , Reduce the effect of labor and material input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Welding target: plate-to-plate butt joint 30×625×1000 (mm).

[0034] Plate: two 30×300×1000 (mm) steel plates; one steel liner 10×40×1000 (mm).

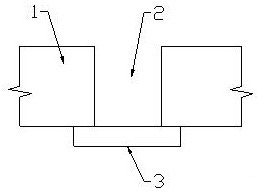

[0035] Blanking: directly cut out the required test plate by flame cutting, and the joint 1 does not have a bevel, that is, the joint form is I-type bevel 2.

[0036] Assembly and fixation: Groove 2 gap 25mm, spot welding steel liner 3 on the back of the weld seam.

[0037] Bottom welding: H10Mn2 with SJ101 flux; wire diameter 4.0mm submerged arc welding wire.

[0038] The welding current is 450-500 (A), the voltage is 30-33 (V), and the welding speed is 37-44 (cm / min). The bottoming welding operation is specifically as follows:

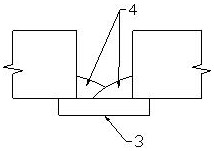

[0039] Rotate the submerged arc welding machine head 10° to the right for right bottoming 41 welding to ensure that the weld seam is fully fused with the side wall gasket. After the right bottoming 41 is completed, its side wall weld seam height is 5-8mm, and the steel liner 3 side weld seam widt...

Embodiment 2

[0045] Welding goal: to make a group of H boxes with a section of 500×270×30 (mm) and a length of 2m.

[0046] Plate: two 30mm×290mm×2m steel plates; two 30mm×270mm×2m steel plates; one steel liner 10mm×40mm×2m.

[0047] Blanking: directly cut out the required test plate by flame cutting, and the joint does not have a bevel, that is, the form of the joint is I-type bevel 2.

[0048] The box-shaped main seam is not grooved, the joint form is I-shaped groove back steel liner 3, and the gap between groove 2 is 25mm.

[0049] Weld each main seam as follows.

[0050] 1. Bottom welding: use H10Mn2 with SJ101 flux, wire diameter 4.0 submerged arc welding wire; welding current is 450-500 (A), voltage is 30-33 (V), welding speed is 37-44 (cm / min) . Rotate the head of the welding machine 10° to the left or right respectively to perform left bottom welding and right bottom welding.

[0051] 2. Filling and covering: use H10Mn2 with SJ101 flux, wire diameter 4.0 submerged arc welding w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com