Metal recovery sorting machine

A sorting machine and metal technology, applied in sorting, magnetic separation, solid separation, etc., can solve the problems of high investment and maintenance costs, high power consumption, low sorting efficiency, etc., and achieve convenient and fast sorting and collection, The effect of reducing the difficulty of sorting operation and improving the efficiency of sorting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to facilitate those skilled in the art to understand the technical solution of the present invention, the technical solution of the present invention will be further described in conjunction with the accompanying drawings.

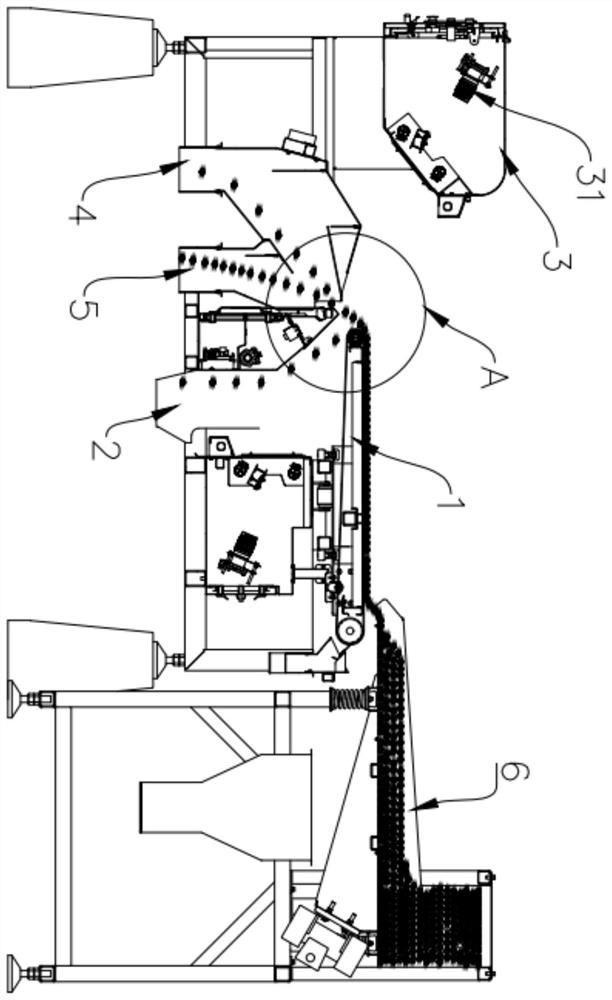

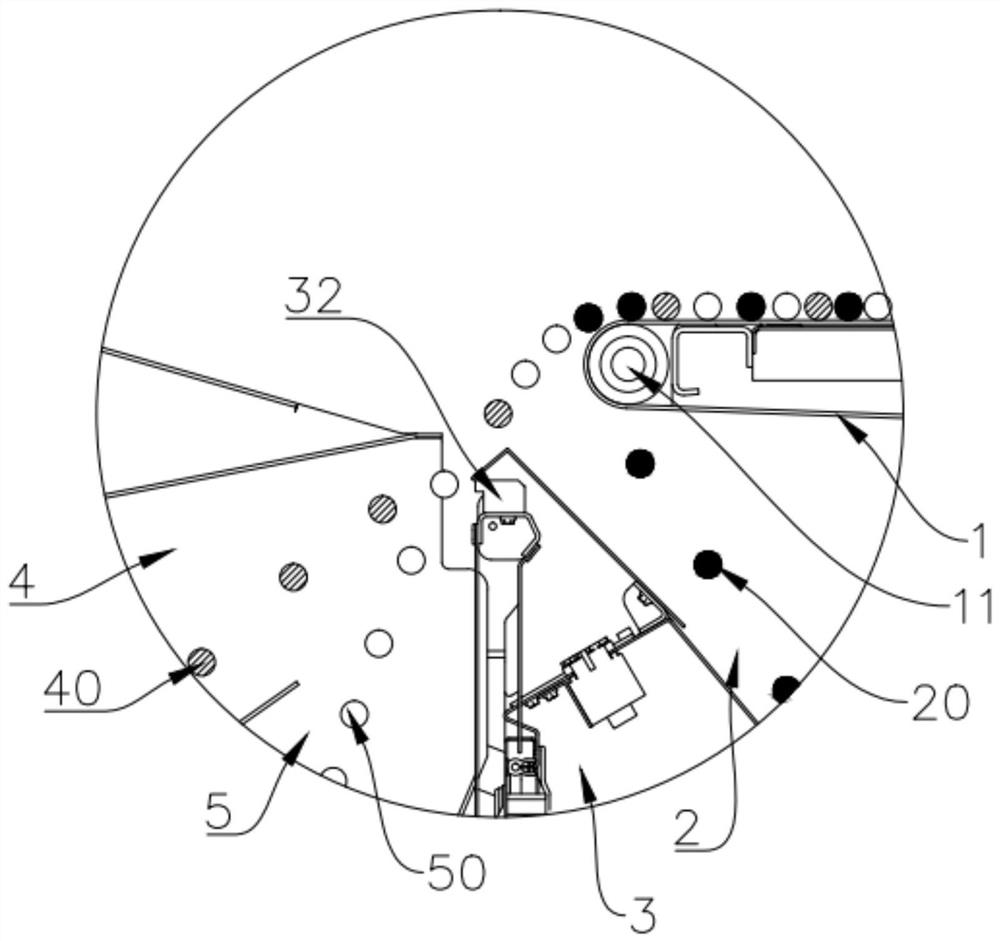

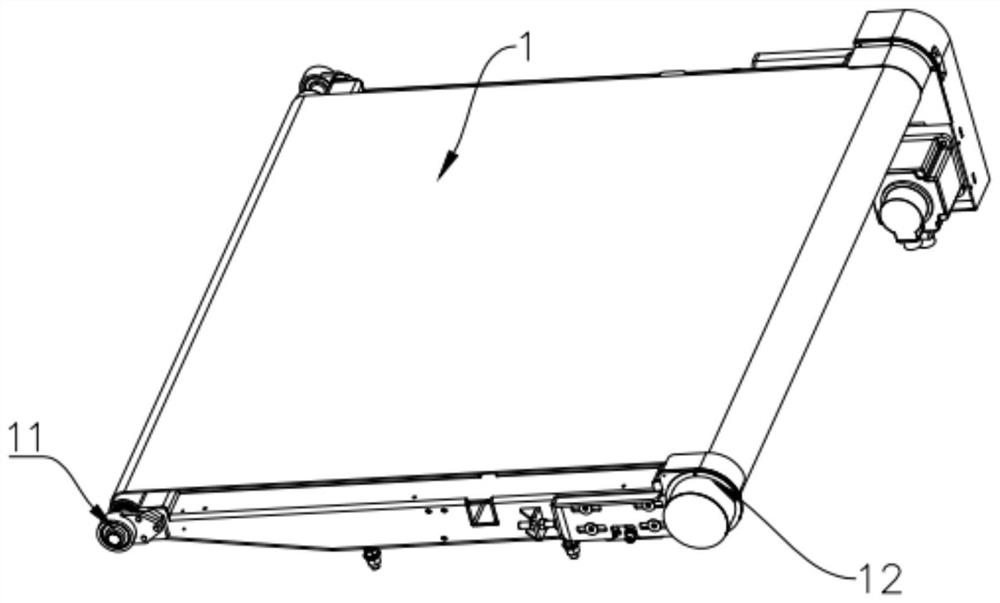

[0021] Such as figure 1 As shown, the technical solution of the present invention is a metal recycling and sorting machine, including a vibrating feeding device 6, a conveyor belt 1, and a magnetic sorting device and a color sorting device arranged at the end of the conveyor belt 1 in sequence. The working process of this sorting machine is to first feed the metal mixture that needs to be sorted and recovered by the vibrating feeding device 6, and then transport it forward to the sorting position through the conveyor belt 1, and then the magnetic sorting device at the sorting position will The magnetically attractive metals are sorted out, and the color sorting and sorting device sorts out the non-ferrous metals, and finally the metals are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com