Glucosamide-terminated polyether surfactant as well as preparation method and application thereof

A surfactant and capped polyether technology, which is applied in chemical instruments and methods, additives, transportation and packaging, etc., can solve the problems of poor biocompatibility and high critical micelle concentration, reduce irritation and improve biological Degradation characteristics, high yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

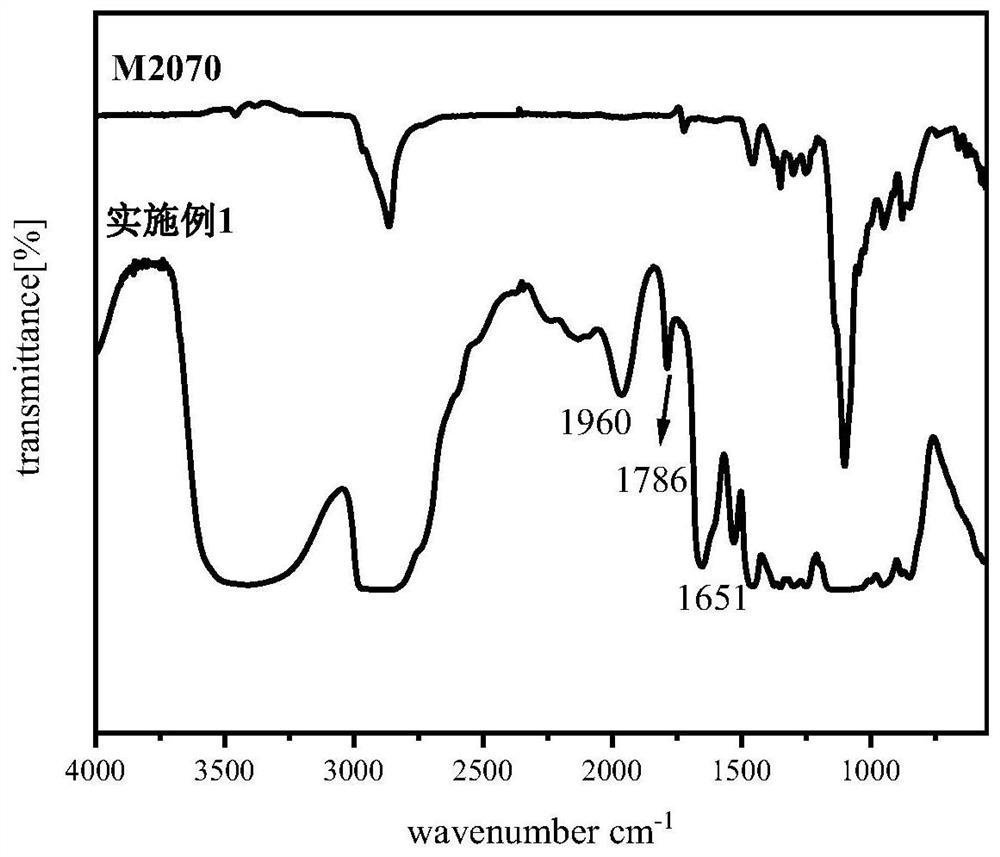

[0031] Preparation of glucosamide-terminated polyether surfactant: Add 20g (about 10mmol) of polyetheramine M2070 and 0.178g (1mmol) of gluconolactone to a mixed solution of 50mL of ethanol and methanol, and control the temperature At 25°C, reflux and stir the reaction for 24h: It can be observed that the color of the solution turns yellow as the reaction progresses. After the reaction, the crude product obtained by the reaction was added to ethanol for cooling and recrystallization, and the ethanol was removed by rotary evaporation to obtain 0.72 g of a yellow liquid (glucosamide-capped polyether surfactant). The yield of polyether surfactant was 33.1%.

[0032] The NMR test result of the yellow liquid that embodiment 1 obtains is as follows:

[0033] 1 H NMR (400MHz, DMSO) δ4.55(s, 5.4H), 3.94(d, J=24.7Hz, 2.1H), 3.54(s, 16.60H), 3.50(d, J=11.5Hz, 124H), 3.41 (d, J = 16.0Hz, 20.25H), 3.35 (d, J = 20.8Hz, 10.11H), 3.24 (s, 4.28H), 1.05 (d, J = 6.2Hz, 30.51H).

[0034] In ...

Embodiment 2

[0039] Preparation of glucosamide-terminated polyether surfactant: 100 g (about 50 mmol) of polyetheramine M2070 and 1.78 g (10 mmol) of gluconolactone were added to 150 mL of n-butanol and isoamyl alcohol mixed solution, Control the temperature at 70°C, reflux and stir the reaction for 48h: It can be observed that the color of the solution turns yellow as the reaction progresses. After the reaction, the crude product obtained by the reaction was added to ethanol for cooling and recrystallization, and the ethanol was removed by rotary evaporation to obtain 15.04 g of a yellow liquid (glucamide-terminated polyether surfactant). The yield of ether surfactant was 68%.

Embodiment 3

[0041] Preparation of glucosamide-terminated polyether surfactant: 40 g (about 20 mmol) of polyetheramine M2070 and 1.78 g (10 mmol) of gluconolactone were added to 80 mL of isopropanol solution, and the temperature was controlled at 60 °C, stirred for 72 hours: It can be observed that the color of the solution turns yellow as the reaction progresses. After the reaction was finished, the crude product obtained from the reaction was added to ethanol for cooling and recrystallization, and the ethanol was removed by rotary evaporation to obtain 18.15 g of yellow liquid (glucosamide-terminated polyether surfactant), which was calculated to obtain glucosamide-terminated polyether The yield of type surfactant was 82%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com