Porous carbon material based on nitrogen-rich covalent organic framework structure and preparation method and application of porous carbon material

A technology of covalent organic framework and porous carbon materials, applied in the preparation/purification of carbon, manufacturing of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., can solve the problems of limiting practical application value and low specific capacitance of carbon materials, Achieve good application prospects, increase specific capacitance, and excellent cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Example 1 A porous carbon material LNU-50-1000 based on a nitrogen-rich covalent organic framework structure

[0039] The preparation method is as follows:

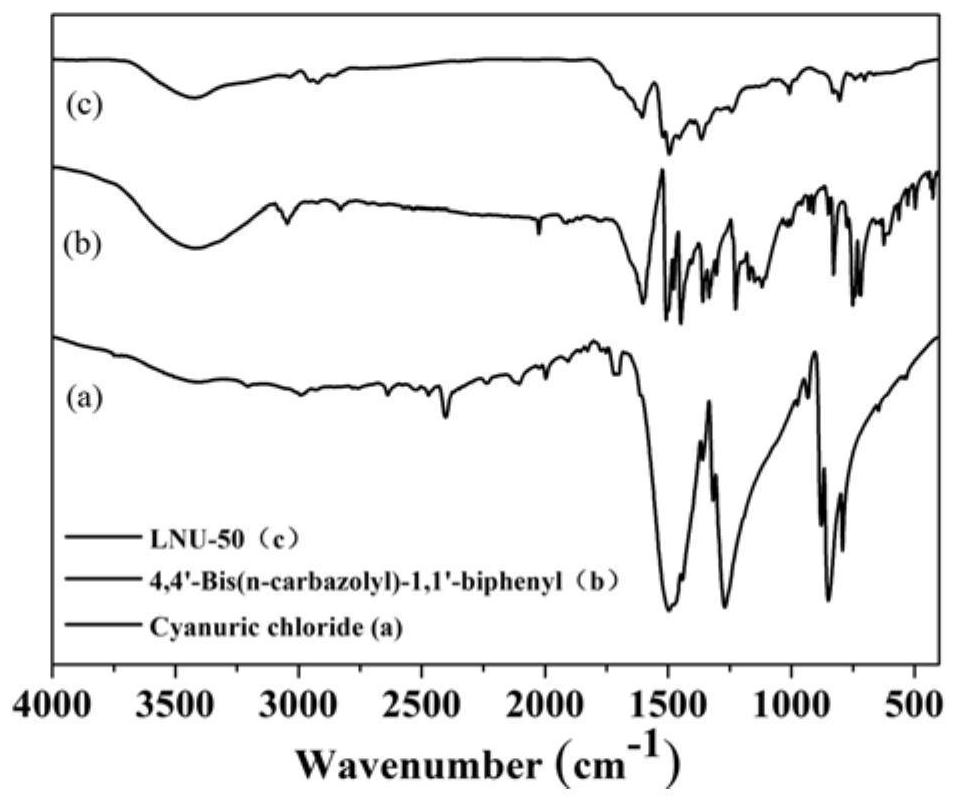

[0040] 1. Synthesis of nitrogen-rich covalent organic framework material LNU-50

[0041] Under a nitrogen atmosphere, 300mg (0.619mmol) of 4,4'-bis(N-carbazole)-1,1'-biphenyl, 152mg (0.825mmol) of cyanuric chloride and 1.072g (8.047mmol) of catalyst without Aluminum trichloride water was added to the round-bottomed flask, and then the oil pump was used to evacuate and nitrogen was circulated repeatedly three times, and then 30 mL of anhydrous and oxygen-free dichloromethane was added to the reaction system by injection. Finally, the reaction system was heated to 70°C and refluxed for 24 hours.

[0042] After the reaction was completed, the reactant was suction filtered to leave solid insoluble matter, which was washed with tetrahydrofuran, deionized water and acetone several times to remove possible unreacted mon...

Embodiment 2

[0047] Example 2 A porous carbon material LNU-51-1000 based on a nitrogen-rich covalent organic framework structure

[0048] The preparation method is as follows:

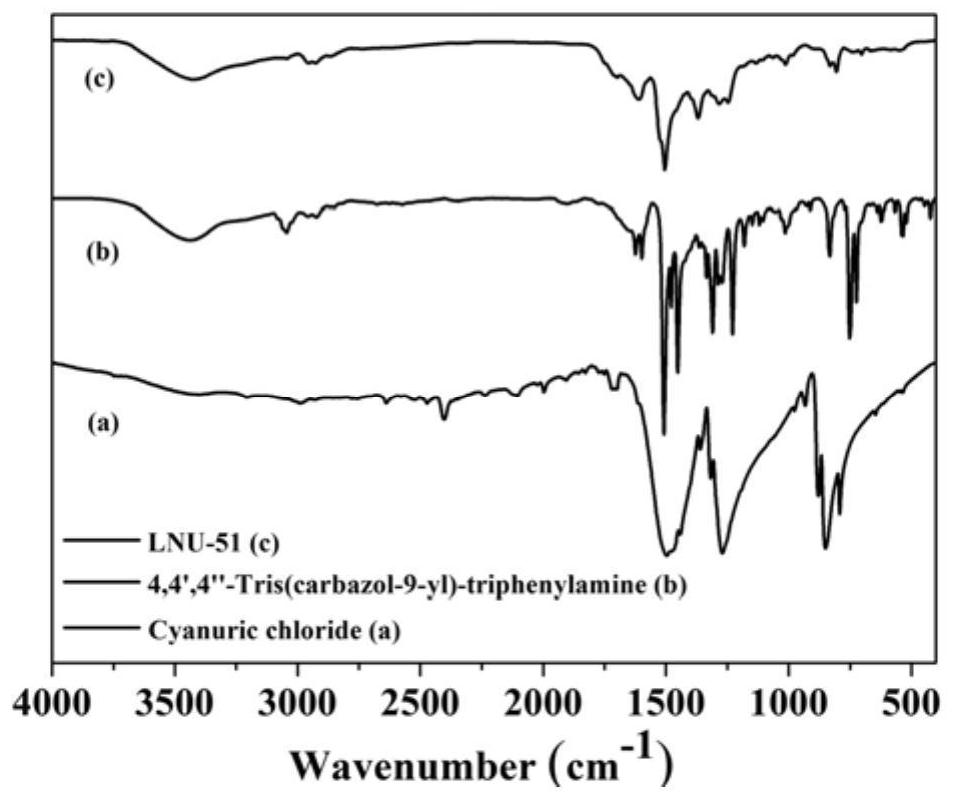

[0049] 1. Synthesis of nitrogen-rich covalent organic framework material LNU-51

[0050] Under nitrogen atmosphere, 300 mg (0.405 mmol) 4,4', 4"-tris(carbazol-9-yl) triphenylamine, 149 mg (0.810 mmol) cyanuric chloride and 701.860 mg (5.263 mmol) catalyst were anhydrous Aluminum trichloride is added in the round-bottomed flask, then evacuated with an oil pump and then circulated with nitrogen for three times, and then 30mL of anhydrous and oxygen-free methylene chloride is added to the reaction system by injection. Finally, the reaction system is heated To 70°C, reflux for 24 hours.

[0051] After the reaction was completed, the reactant was suction filtered to leave solid insoluble matter, which was washed with tetrahydrofuran, deionized water and acetone several times to remove possible unreacted monomer or res...

Embodiment 3

[0056] Example 3 A porous carbon material LNU-52-1000 based on a nitrogen-rich covalent organic framework structure

[0057] The preparation method is as follows:

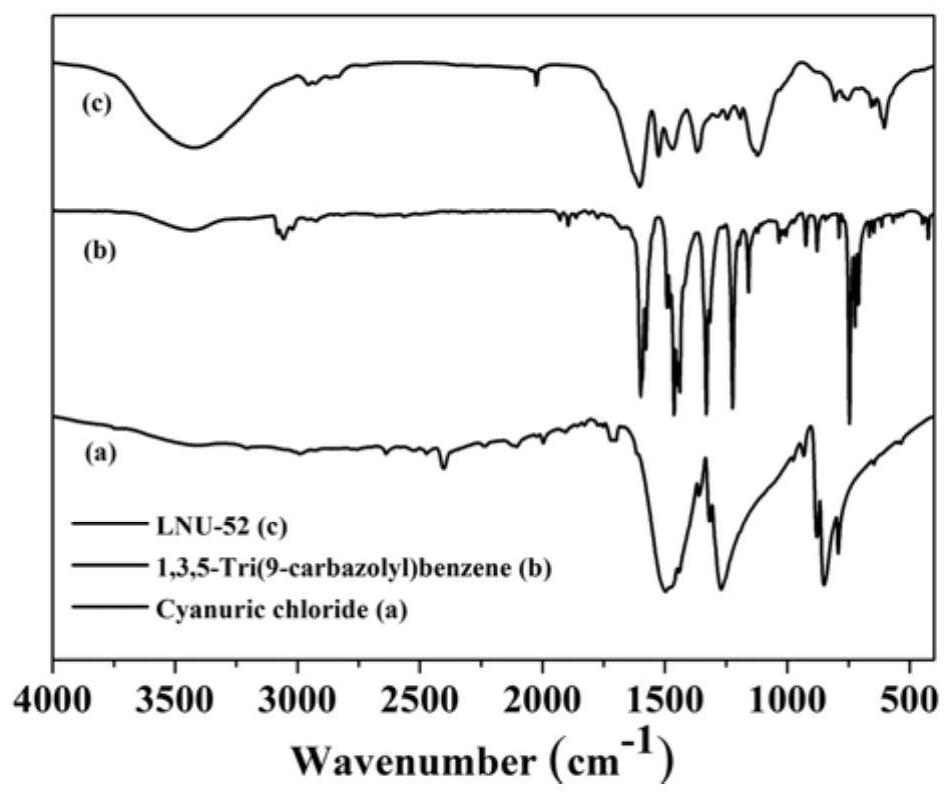

[0058] 1. Synthesis of nitrogen-rich covalent organic framework material LNU-52

[0059] Under nitrogen, 300mg (0.523mmol) of 1,3,5-tris(9-carbazolyl)benzene, 193mg (1.046mmol) of cyanuric chloride and 906.580mg (6.799mmol) of catalyst anhydrous trichloride Aluminum was added to the round-bottomed flask, then the oil pump was used to evacuate and nitrogen was circulated repeatedly three times, and then 30 mL of anhydrous and oxygen-free dichloromethane was added to the reaction system by injection. Finally, the reaction system was heated to 70°C and refluxed for 24 hours.

[0060] After the reaction was completed, the reactant was suction filtered to leave solid insoluble matter, which was washed with tetrahydrofuran, deionized water and acetone several times to remove possible unreacted monomer or residual catal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com