Method for checking static strength of connecting pipe bearing internal pressure and various external loads

A static strength and calibration technology, applied in the field of pressure equipment, can solve problems such as no data calibration method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

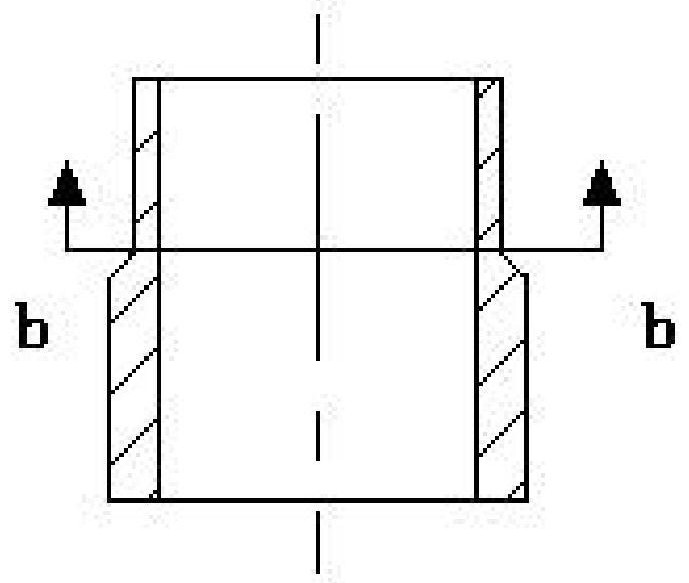

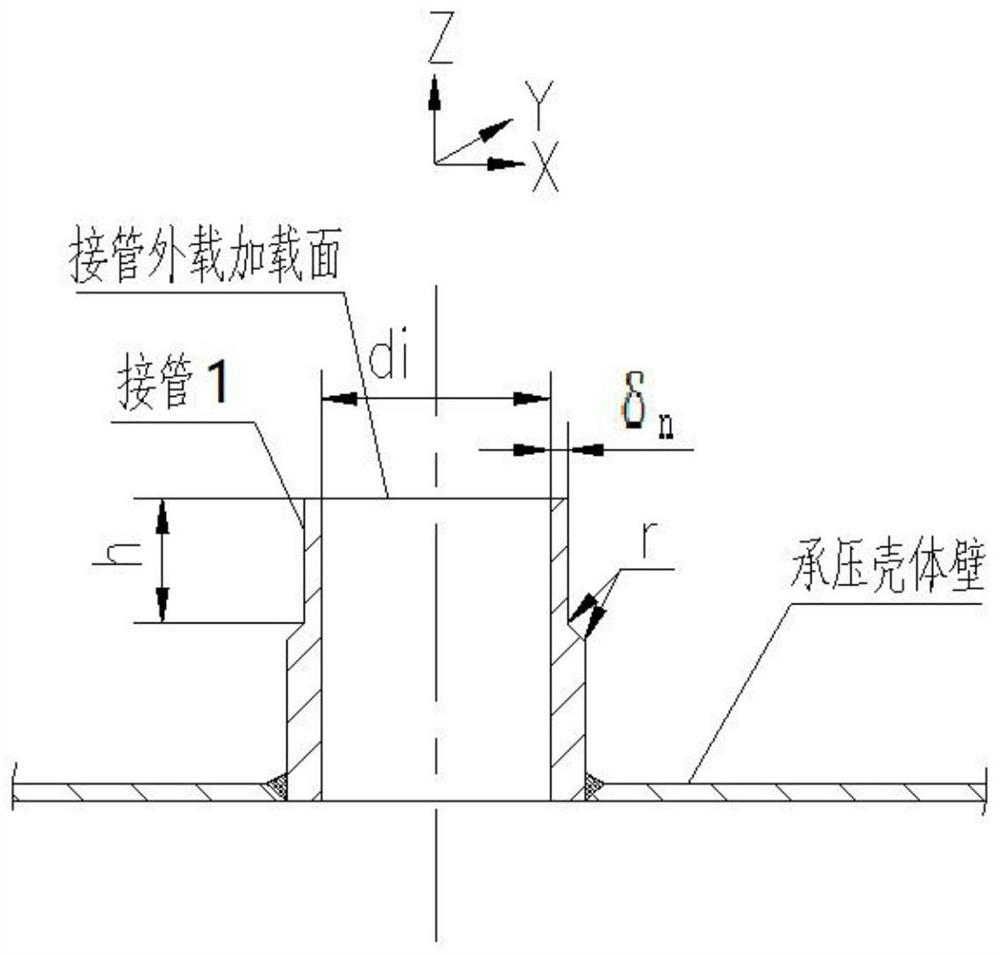

[0079] Specific implementation mode one: combine Figure 1-Figure 4 Describe this embodiment, a method for checking the static strength of a connecting pipe subjected to internal pressure and various external loads in this embodiment, including a connecting pipe 1, the connecting pipe 1 is a reduced-diameter connecting pipe, and the connecting pipe 1 includes a thin pipe section, a variable-diameter section The connection between the thick pipe section, the thin pipe section and the variable diameter section is the position with the lowest strength, that is, the b-b section, check the strength of the b-b section, and the strength of the connection can be guaranteed. The thin pipe section is connected to the pipeline, and the thick pipe section is connected to the pressure-bearing shell wall , the variable diameter of the connecting pipe 1 is a b-b section, characterized in that the specific check method includes the following steps:

[0080] Step ⅰ, checking the wall thickness...

specific Embodiment approach 2

[0084] Specific implementation mode two: combination Figure 1-Figure 4 Describe this embodiment, a method for checking the static strength of a connecting pipe that bears internal pressure and various external loads in this embodiment, in the step i, check the wall thickness δ of the connecting pipe b-b section nt The methods include:

[0085] Step ⅰ1. Check the connection and calculate the internal pressure P C ;

[0086] P C ≤0.4[σ] t φ(1);

[0087] where [σ] t - allowable stress at material design temperature, φ - welding joint coefficient;

[0088] Step ⅰ2, taking over the wall thickness δ nt ;

[0089]

[0090] In the formula, d i - take over check section inner diameter, figure 2 δ in n It is the wall thickness actually selected for the pipe.

specific Embodiment approach 3

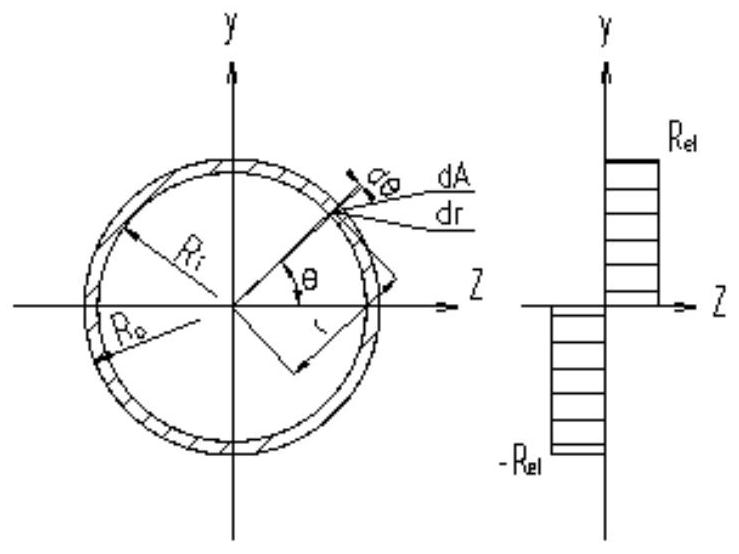

[0091] Specific implementation mode three: combination Figure 1-Figure 4 Describe this embodiment, a method for checking the static strength of a nozzle that bears internal pressure and various external loads in this embodiment, in the step ii, check the equivalent film and pure Methods for shear stress values include:

[0092] Step ⅱ1. Calculate the hoop membrane stress σ generated on the b-b section wall of the connecting pipe due to the internal pressure θ ;

[0093]

[0094] In the formula, K-the ratio of the outer diameter to the inner diameter of the connecting pipe;

[0095] Step ii2. Calculate the axial membrane stress σ produced by the internal pressure on the b-b section wall of the connecting pipe LP ;

[0096]

[0097] Step ii3. Calculate the radial membrane stress σ produced by the internal pressure on the b-b section wall of the connecting pipe rP ;

[0098]

[0099] Step ii4. Calculate the axial bending membrane stress σ produced by the load be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com