Water-washing pulp fluffing and drying equipment for sanitary towel production line

A technology of drying equipment and production line, which is applied in pulp bleaching, pulp dehydration, etc., and can solve problems such as uneven cotton balls, difficulty in flattening and drying, and sticking of push handles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

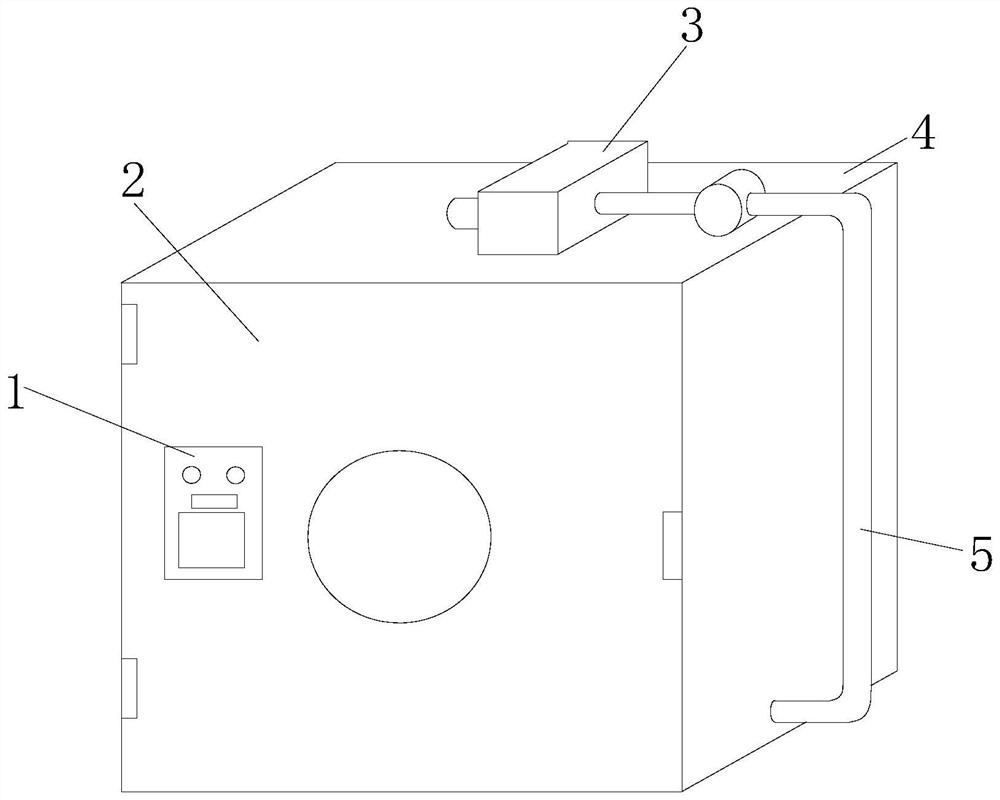

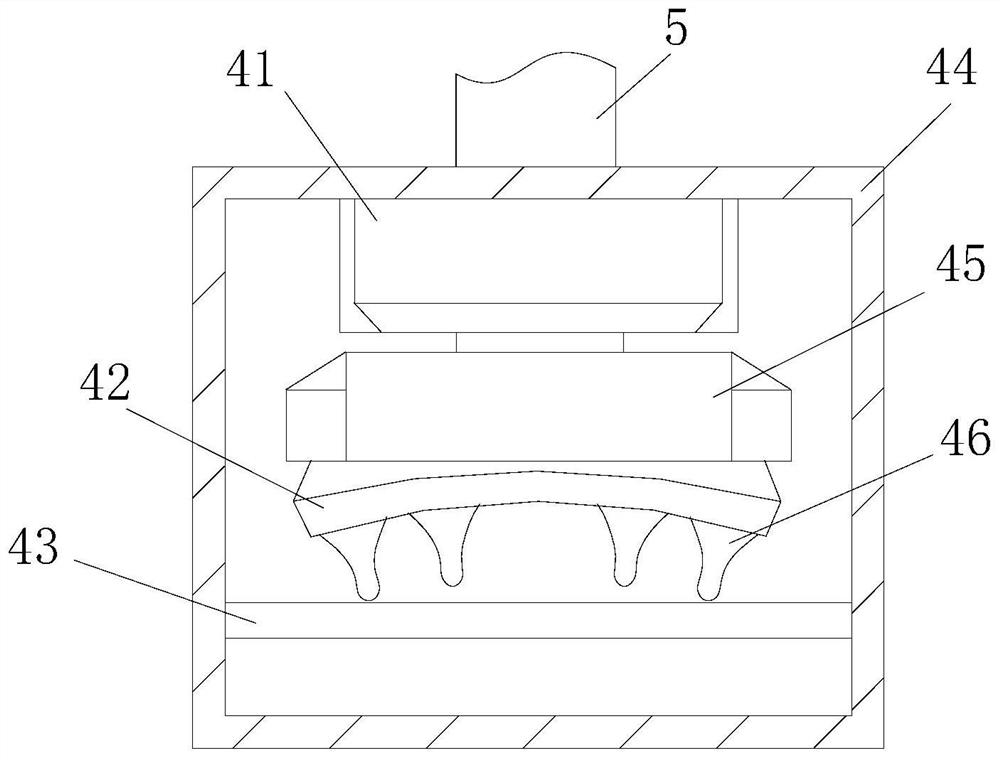

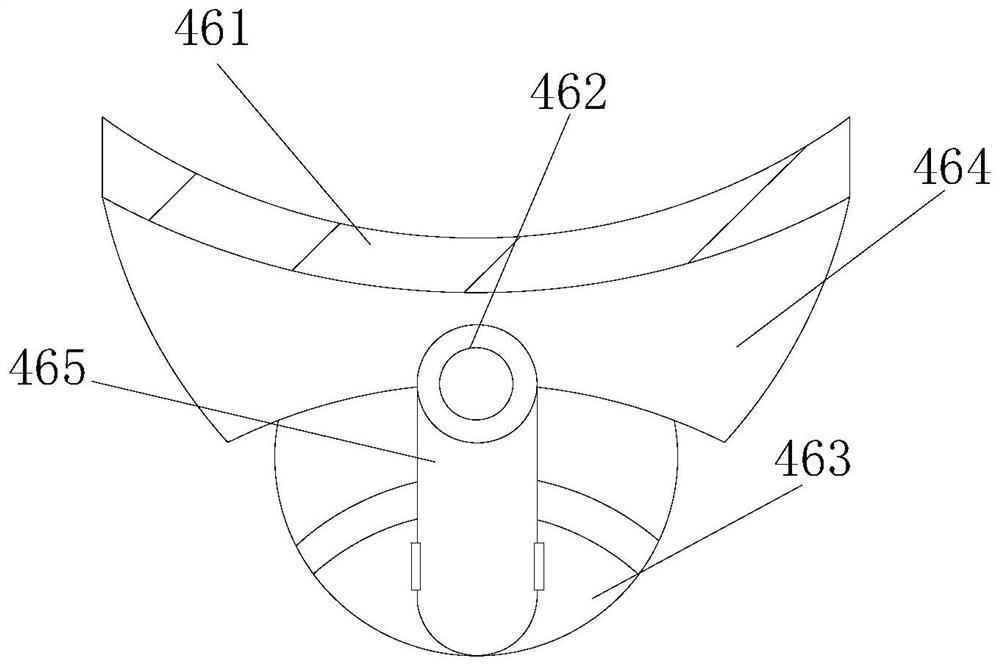

[0027] like Figure 1-Figure 3 As shown, the present invention provides a fluffy drying equipment for washed pulp in a sanitary napkin production line. Above, the switch door 2 is hingedly connected to one side of the cabinet 4, the motor 3 and the conduit 5 are installed on the cabinet 4, and the cabinet 4 includes a transport rail 41, a crane 42, a drying table 43, a body 44, connecting part 45, push handle 46, the top of the body 44 is fixedly connected with the conduit 5, and its interior is welded and connected with the transport rail 41 and the drying table 43, the bottom of the transport rail 41 is slidably fitted with a connecting part 45, and the connecting part 45 is equipped with more than two push handles 46 through the crane 42, and the push handle 46 includes a injection cutting layer 461, a cylinder 462, a pressing device 463, a through cavity 464, and an auxiliary cutting structure 465. The injection cutting layer 461. The scarf connection is connected to the...

Embodiment 2

[0029] like Figure 4-Figure 7 As shown, on the basis of Embodiment 1, the present invention combines the mutual cooperation of the following structural components, and the crushing device 463 includes a swing ring 3a1, a screw 3a2, an elastic layer 3a3, a friction ring 3a4, and a cloth pressure plate 3a5 , the pendulum ring 3a1 is rotated and fitted on the friction ring 3a4 through the screw 3a2, more than two screw 3a2 are arranged between the friction ring 3a4 and the cloth pressure plate 3a5, and the two sides of the cloth pressure plate 3a5 An elastic release layer 3a3 is fixedly connected, and is rotatably fitted on the bottom of the through cavity 464. The elastic release layer 3a3 is a hollow structure, and its hollow opening has certain elasticity, and the size of its opening will be changed according to the extrusion of the auxiliary cutting structure 465. As a guide for the height change of the auxiliary cutting structure 465, the deformation and energy absorption c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com