A self-heating body formed by compression molding and its preparation method

A compression molding and self-heating technology, which is applied in the direction of chemical instruments and methods, heating appliances for treatment, heat exchange materials, etc., can solve the problem of high production finished products, non-woven materials with strong air permeability and stability dependence, etc. problem, to achieve the effect of long heating time, miniaturization of product volume and reduction of manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] According to the second aspect provided by the embodiments of the present invention, a method for preparing a compression molded self-heating body is provided, including the following steps:

[0038] Step 1: mixing of materials;

[0039] Step 2: molding;

[0040] Step 3: Pack and seal.

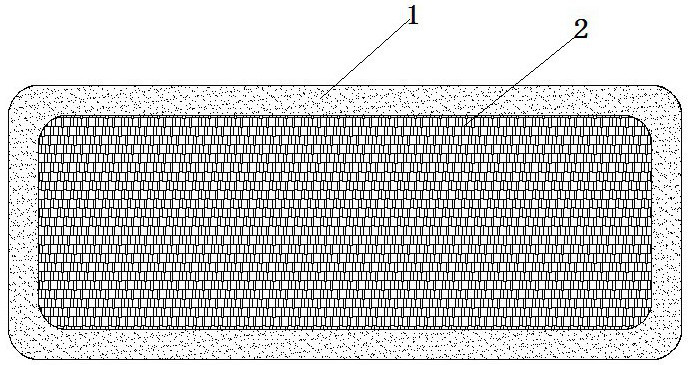

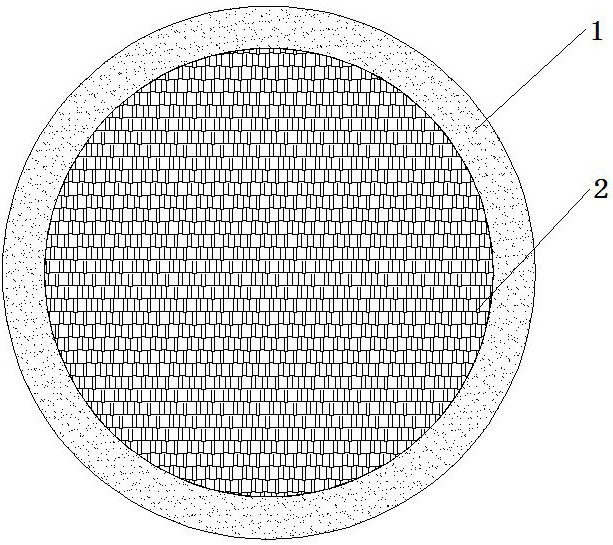

[0041] According to a specific embodiment provided by the present invention, the molding step includes the step of covering the heat-generating inner core material with the shell material, and the compression molding is primary compression molding or secondary compression molding. The application fields of the compression-molded self-heating body are different, and the gas permeability requirements of the casing 1 are different. According to the different requirements of gas permeability, the casing 1 can be molded once or twice.

Embodiment 1

[0051] The components of the heating inner core 2 consist of:

[0052] Iron powder 55%; Activated carbon powder 8%; Vermiculite 5%; Water absorbent resin 2%; Sodium chloride 4%; Water 26%;

[0053] The components of the shell 1 consist of:

[0054] Diatomaceous Earth 88%; Polyvinyl Alcohol 2%; Water 10%.

[0055] Concrete preparation process is as follows:

[0056] Step 1: Mix the materials of the heating inner core 2: mix the iron powder, activated carbon powder, vermiculite, water-absorbing resin, sodium chloride and water according to the general mixing process, and seal them in the barrel for later use.

[0057] Step 2: Mix the materials of the shell 1: add the polyvinyl alcohol into the water at 80°C under stirring, dissolve and mix evenly, add the diatomaceous earth under continuous stirring, mix evenly, and seal it in the material Reserved in the barrel.

[0058] Step 3: Molding the heating inner core 2: inject 6g-8g (the weight of the filler is adjusted according t...

Embodiment 2

[0063] The components of the heating inner core 2 consist of:

[0064] Iron powder 55%; Activated carbon powder 8%; Vermiculite 5%; Water absorbent resin 2%; Sodium chloride 4%; Water 26%;

[0065] The components of the shell 1 consist of:

[0066] Vermiculite 95%; Water 5%.

[0067] Step 1: Mix the materials of the heating inner core 2: mix the iron powder, activated carbon powder, vermiculite, water-absorbing resin, sodium chloride, and water according to the general mixing process, and seal them in the barrel for later use.

[0068] Step 2: Mix the materials of the shell 1: directly mix 20 mesh 95% vermiculite and 5% water evenly, and seal it in the barrel for later use.

[0069] Step 3: Sub-area blanking: spread 2g-4g (filler weight according to mold volume and inner core size) of the uniformly mixed shell 1 material on the bottom of the mold, and use 6g-8g (filler weight according to Mold volume adjustment) The homogeneously mixed material of the heating inner core 2 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com