Maintenance method for maintaining crane

A technology for cranes and maintenance modules, applied in cranes, load hanging elements, transportation and packaging, etc., can solve problems such as being unsuitable for maintenance operations, driving, and inability to remote personnel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

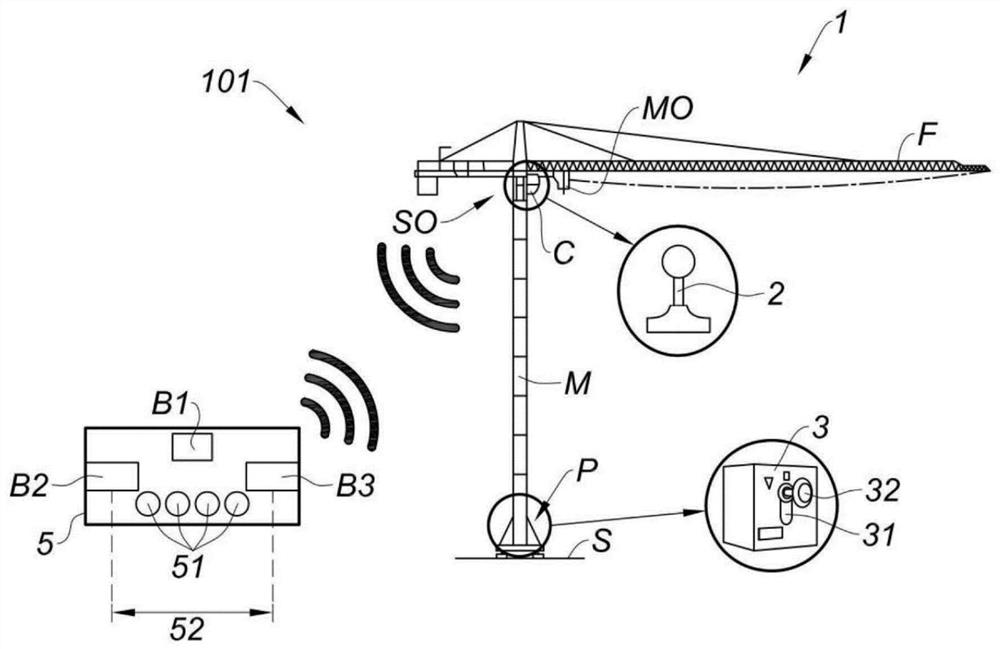

[0161] figure 1 A crane 1 according to the invention is shown comprising a mast M extending substantially in a vertical direction V (perpendicular to the ground S on which the mast M is arranged) and supporting a jib F which F is substantially horizontal and articulated in rotation relative to mast M.

[0162] Thus, the mast M has a foot P located near the ground S and a top SO located near its articulation with the jib F.

[0163] The crane 1 also comprises a cab C fastened to the top SO of the mast M or to the jib F and in which the driving device 2 is arranged.

[0164] This drive device 2 is arranged to be manipulated by the crane operator present in the cab C in order to perform various maneuvers of the crane. In a variant not shown, the drive is a radio-controlled drive for remote actuation by the crane operator.

[0165] For example, the crane operator can drive the horizontal pivotal movement of the boom F relative to the mast M through the drive device 2, or drive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com