Suction cup group for sucking multiple wafers

A suction cup, wafer technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

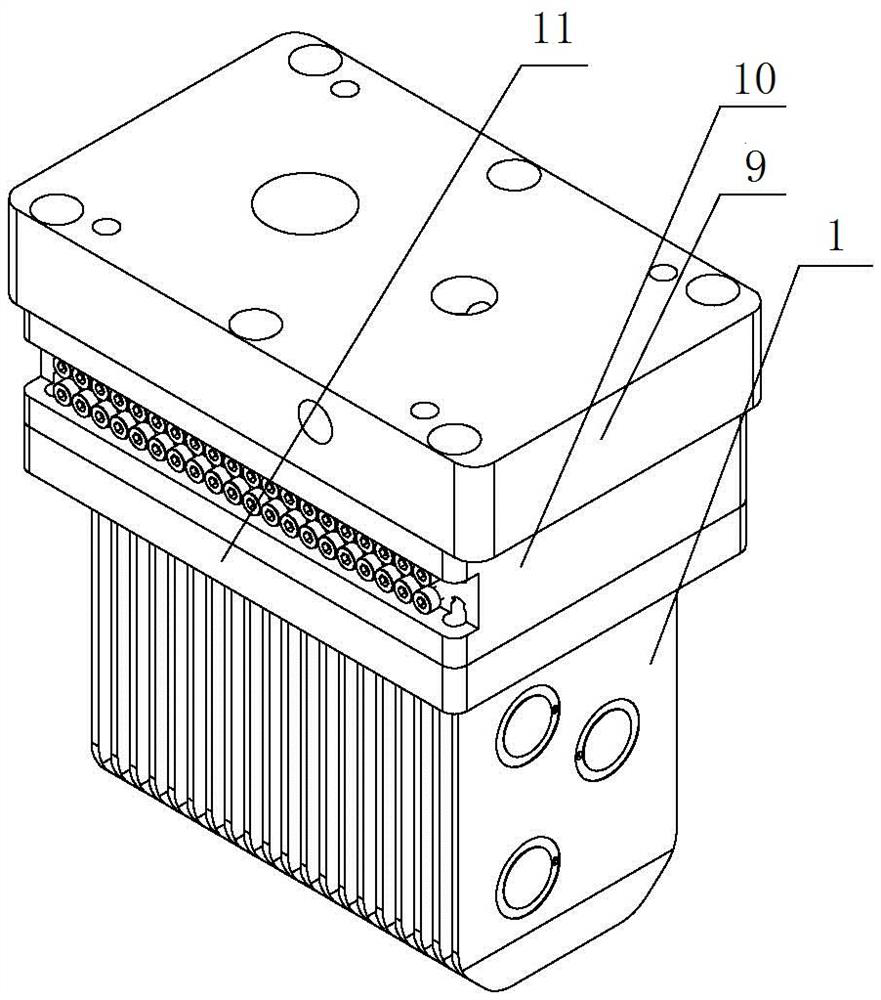

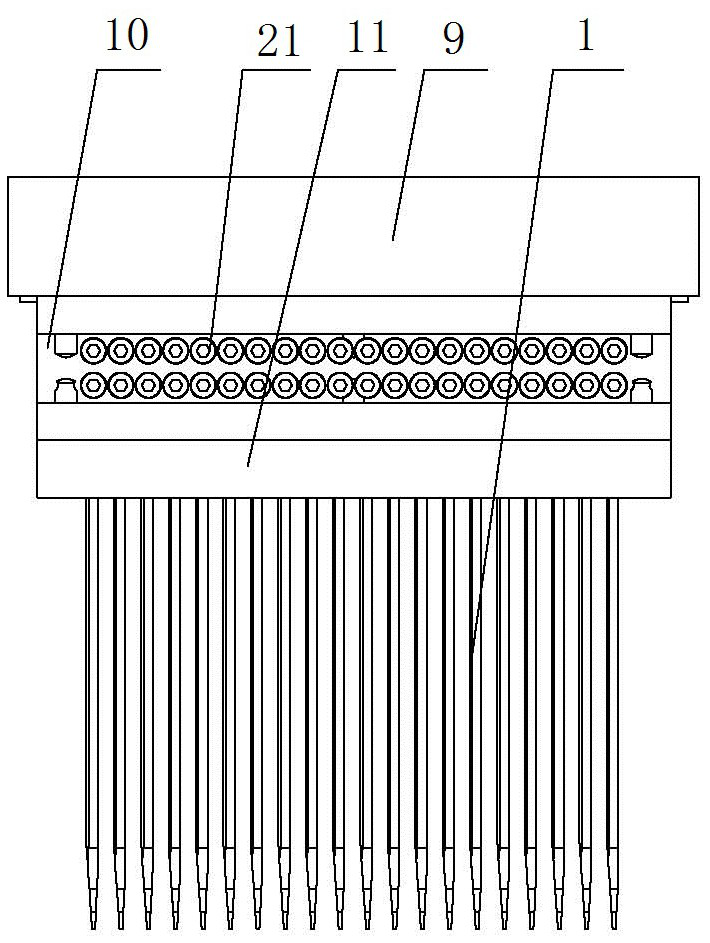

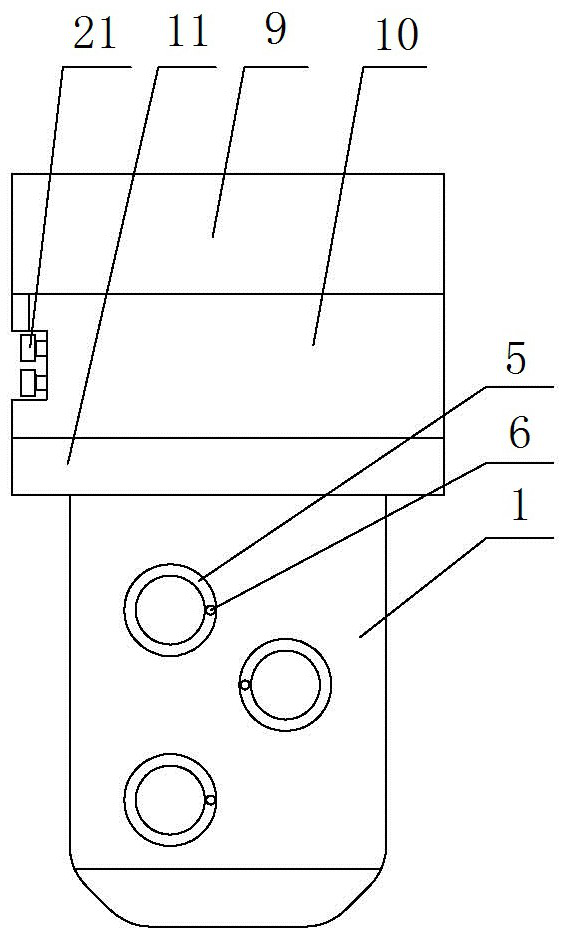

[0016] See Figure 1 to Figure 6 As shown, a suction cup group for picking up multiple wafers includes a suction cup 1 and a mount 2. The suction cup 1 includes at least two and is arranged side by side at intervals. The suction cup 1 includes a mounting area 3 and an adsorption area 4. The front side of the adsorption area 4 A vacuum diversion air channel 5 is provided, and the vacuum diversion air channel 5 includes three annular air channels. The vacuum diversion air channel 5 is provided with a vacuum port 6, and the front of the installation area 3 is higher than the front of the adsorption area 4. The front of the 3 is provided with a sliced air passage 7, and the end is provided with a suction cup vacuum inlet 8, the suction cup vacuum inlet 8 communicates with the vacuum port 6 through the communication air passage inside the suction cup 1, and the mounting seat 2 includes a fixedly connected Gas distribution plate 9, suction cup fixing seat 10, sealing pressure plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com