Spherical all-welded ball valve middle channel double-gun submerged arc welding device and welding process

A fully welded ball valve, submerged arc welding technology, applied in welding equipment, welding accessories, arc welding equipment and other directions, can solve the problems of rough welding seam surface, cumbersome process, easy melting of welding wire and spatter, etc., to reduce welding stress level, The effect of ensuring welding quality, reducing the amount of deposited metal and welding heat input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

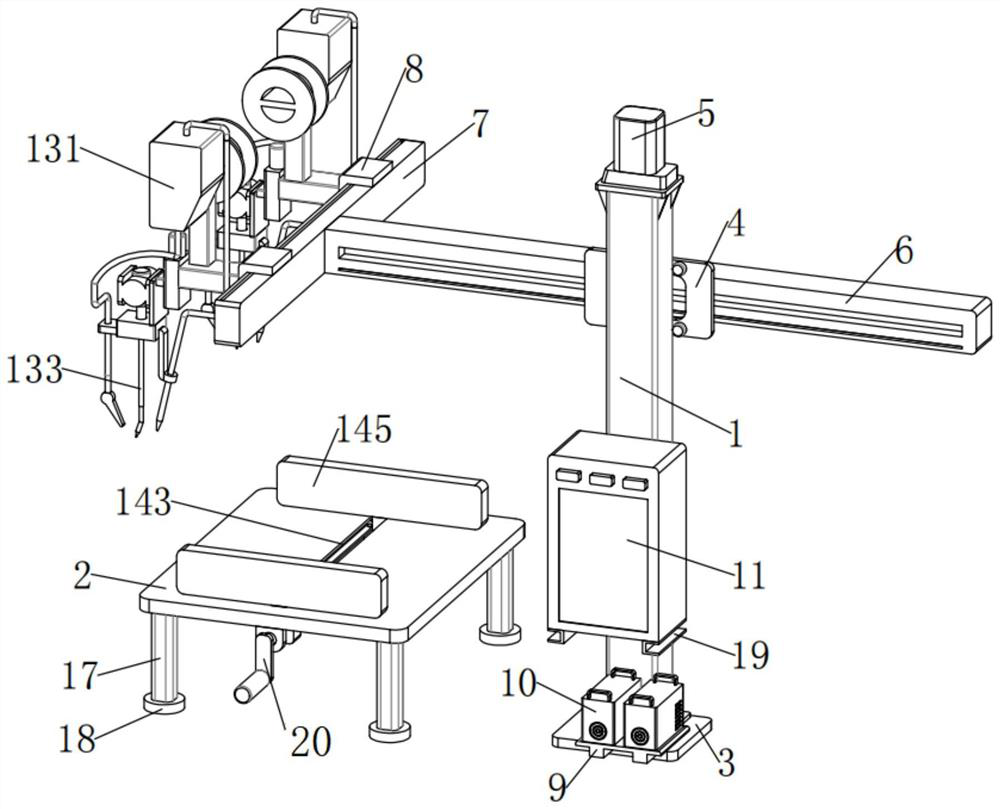

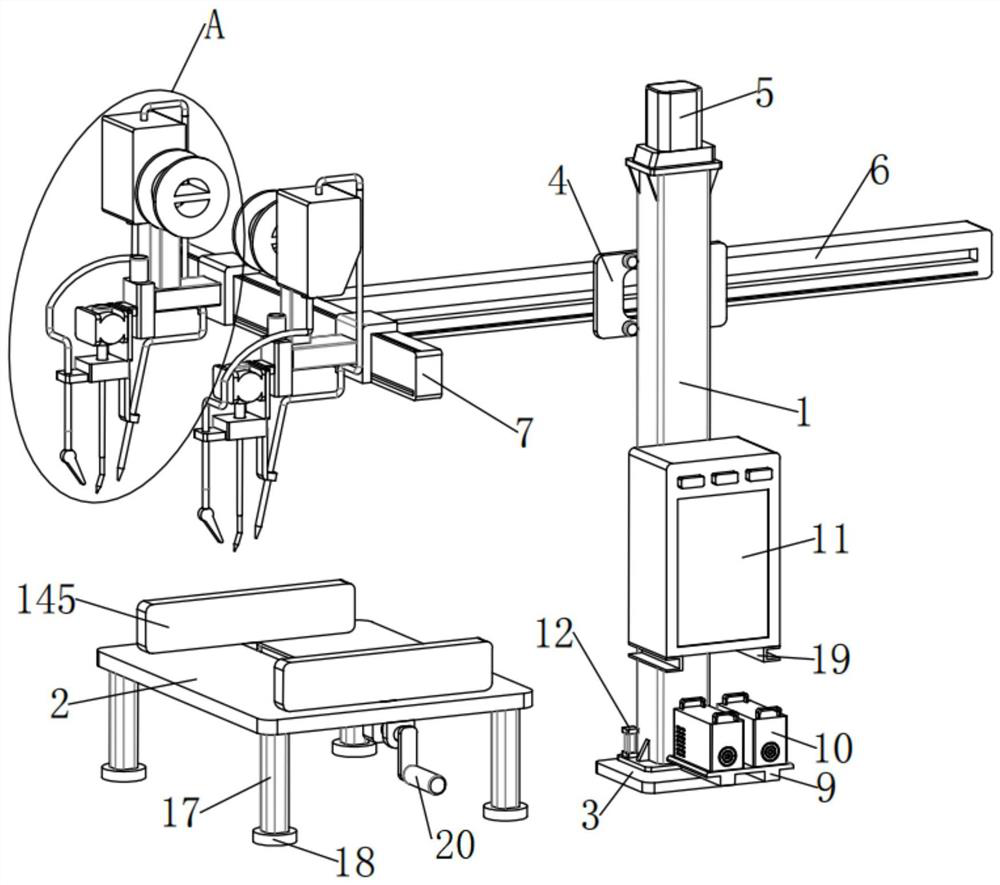

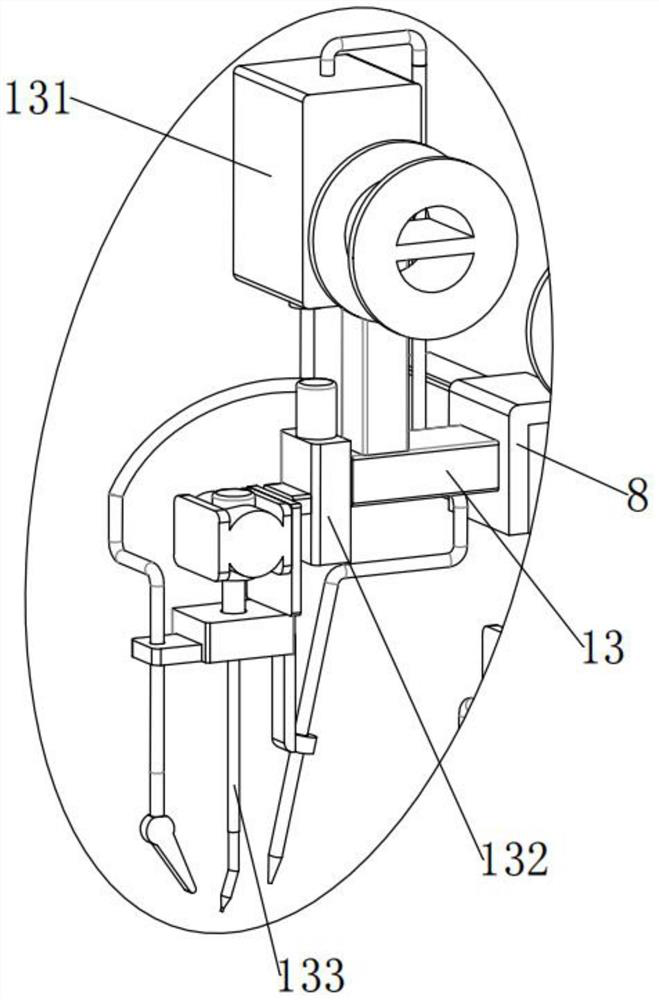

[0031] see Figure 1-5 , the present invention provides the following technical solutions:

[0032] A spherical full-welded ball valve middle channel double-gun submerged arc welding device, including a column 1 and a placing table 2, the placing table 2 is located on one side of the column 1, the lower end of the column 1 is fixedly connected with an installation base 3, and the rear end of the column 1 The lifting slide 4 is slidingly connected, the upper end of the column 1 is fixedly connected with the driving mechanism 5, the rear end of the lifting slide 4 is slidingly connected with the cross beam 6, the left end of the cross beam 6 is fixedly connected with the T-beam 7, and the left end of the T-beam 7 is slidingly connected with Two traversing slides 8, the left ends of the two traversing slides 8 are provided with a group of welding mechanisms, the two sets of welding mechanisms correspond to the placement platform 2, a set of fixing mechanisms are arranged on the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com