Manufacturing method of large ship reception chamber suitable for dry type ship compartment

A manufacturing method and a technology of a ship-bearing box, applied in the direction of ship lifting device, vertical lifting of ship machinery, construction, etc., can solve the problems of inability to carry out overall hoisting and installation, reduce the total amount of welding heat input, increase restraint and control component deformation , Optimize the effect of welding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

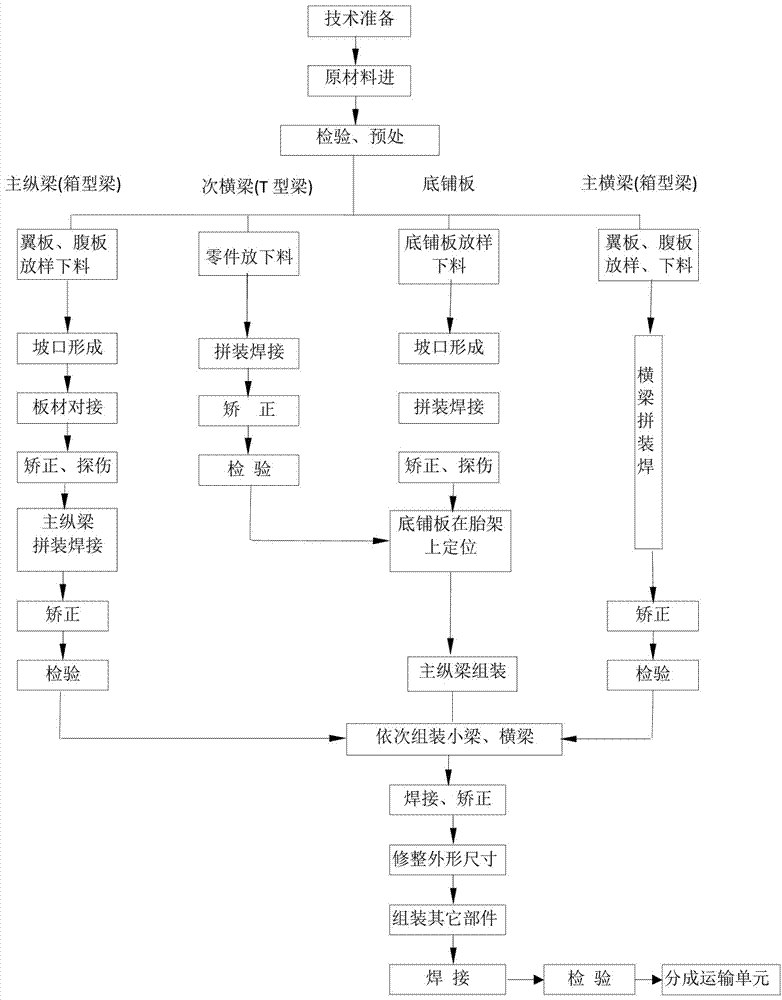

[0126] The embodiments of the present invention will be further described below in conjunction with the drawings.

[0127] This embodiment uses an actual engineering project as an example to illustrate the present invention in detail:

[0128] Project Overview:

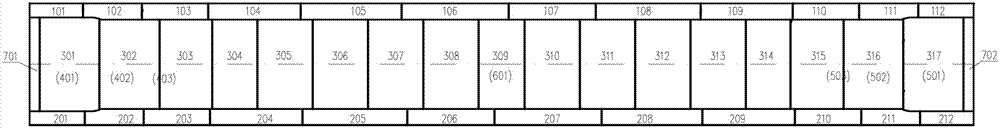

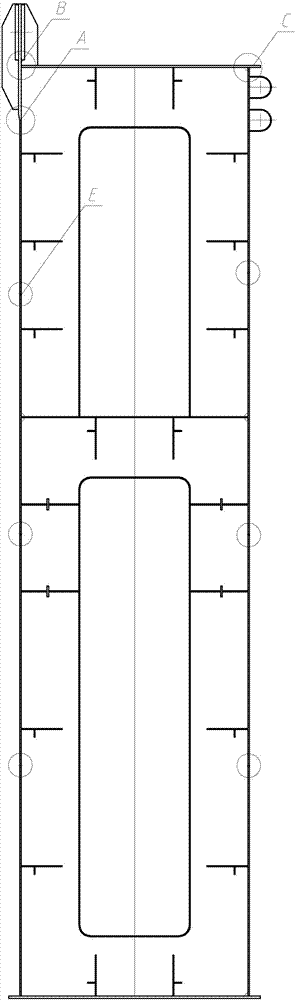

[0129] In this project, the ship lift of the water conservancy project adopts a wire rope hoisting full-balance vertical lifting type, with a passing scale of 2×500, an effective water area of 116.0×12.0×2.5m (length×width×water depth), and a maximum lifting height of 85.4m , The total weight of the cabin is about 6,250 tons, and the weight of the cabin structure is about 1,100 tons. The carrier body is a steel trough-shaped thin-walled structure, with a reclining gate at both ends. When the gate is closed, the cabin is formed The closed waters provide wet transportation conditions for navigable ships to pass the dam. The cabin is composed of a cabin structure and cabin equipment. The cabin structure includes the main st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| verticality | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com