All-position automatic welding machine for pipeline

An automatic welding machine, all-position technology, applied in welding equipment, welding accessories, arc welding equipment, etc., can solve the problems of large overall height and volume, bumping pipes, manual installation, etc., to improve efficiency and automation, and improve compactness degree, the effect of reducing height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

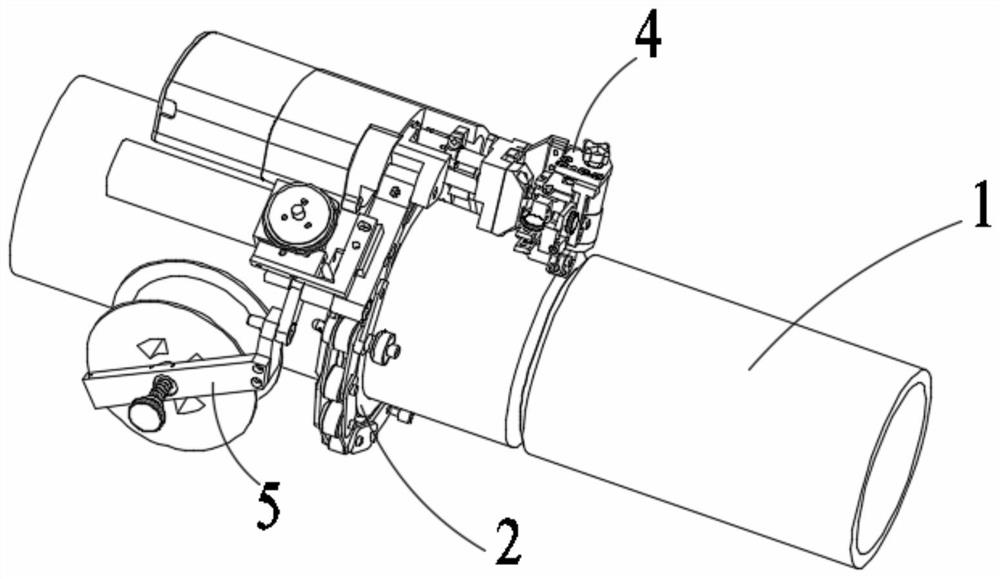

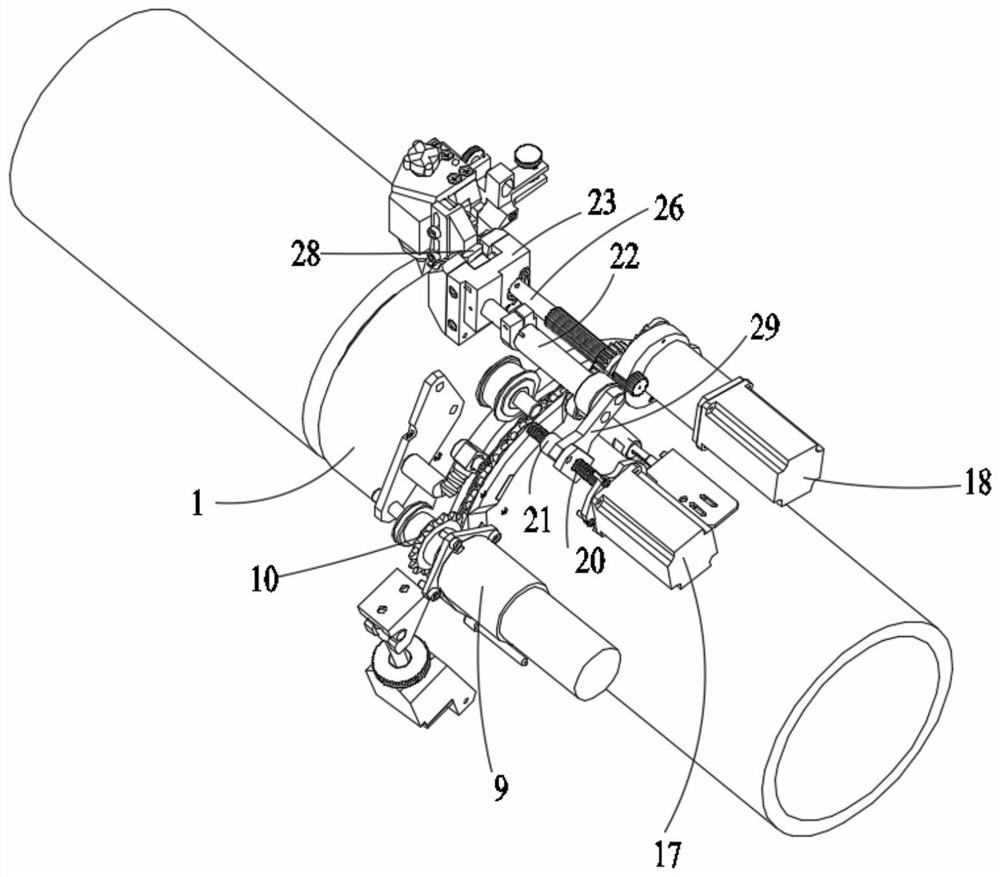

[0041] Embodiment 1: An all-position automatic welding machine for pipelines, including a circular track 2 installed along the circumference of the pipeline 1, a running mechanism 3, a welding mechanism 4, and a wire feeding mechanism 5. The walking mechanism 3, the welding mechanism 4, and the wire feeding mechanism 5. Lay flat along the circumferential direction of the pipeline 1, the welding mechanism 4 and the wire feeding mechanism 5 are connected with the running mechanism 3 and can move around the pipeline 1 with the running mechanism 3;

[0042] The inner wall of the annular track 2 is provided with two projections 13 at intervals in the circumferential direction, and the end surface of the projection 13 slightly protrudes from the inner wall surface of the annular track 2 for surface contact with the pipeline 1, and also has a 2 radially arranged jacking wires 14, one end of the jacking wires 14 can protrude from the circular track 2 and contact with the pipe 1 surface...

Embodiment 2

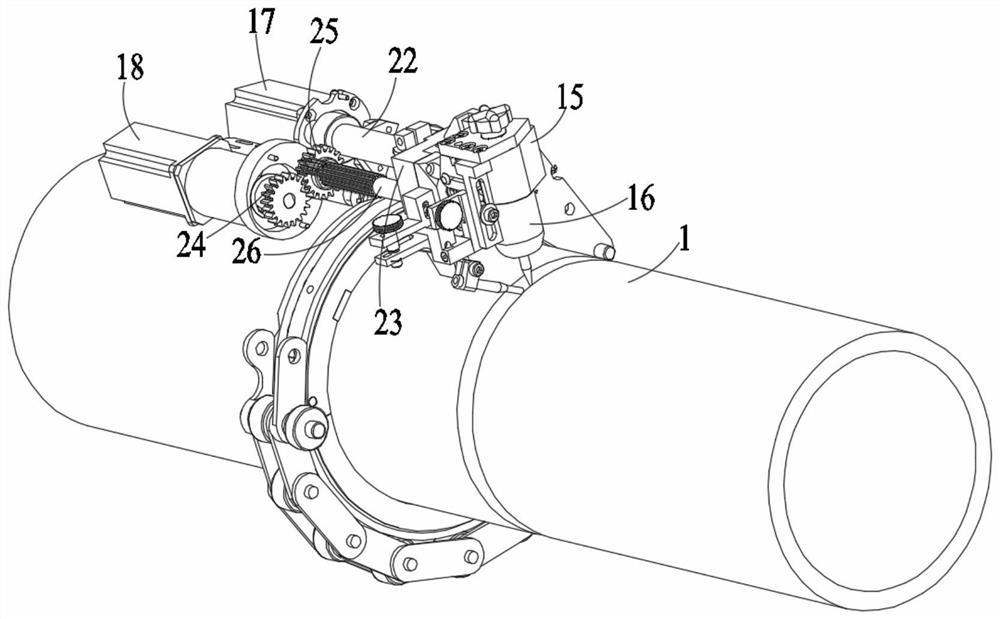

[0056] Embodiment 2: An all-position automatic welding machine for pipelines, including a circular track 2 installed along the circumference of the pipeline 1, a running mechanism 3, a welding mechanism 4, and a wire feeding mechanism 5. The walking mechanism 3, the welding mechanism 4, and the wire feeding mechanism 5. Lay flat along the circumferential direction of the pipeline 1, the welding mechanism 4 and the wire feeding mechanism 5 are connected with the running mechanism 3 and can move around the pipeline 1 with the running mechanism 3;

[0057] The inner wall of the annular track 2 is provided with two projections 13 at intervals in the circumferential direction, and the end surface of the projection 13 slightly protrudes from the inner wall surface of the annular track 2 for surface contact with the pipeline 1, and also has a 2 radially arranged jacking wires 14, one end of the jacking wires 14 can protrude from the circular track 2 and contact with the pipe 1 surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com