Selective resetting lost motion engine valve train components

A selective and component-based technology, applied in engine components, combustion engines, engine control, etc., can solve problems such as low compression ratio, difficult cold start engine, etc., and achieve the effect of eliminating demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

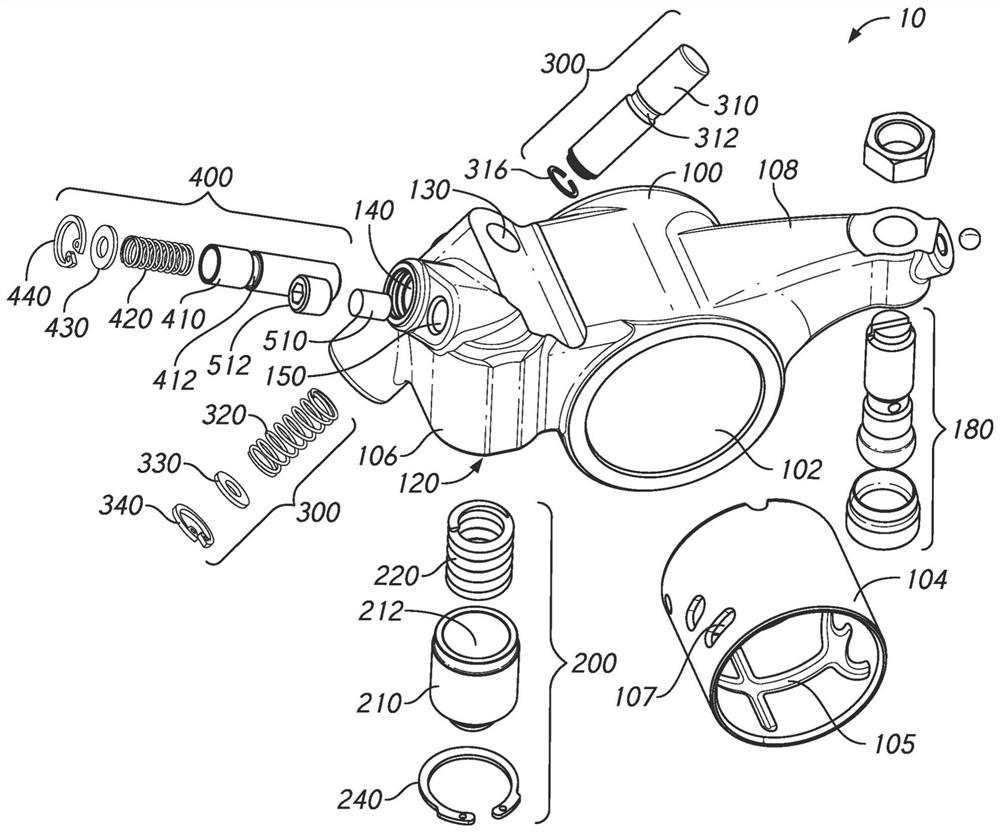

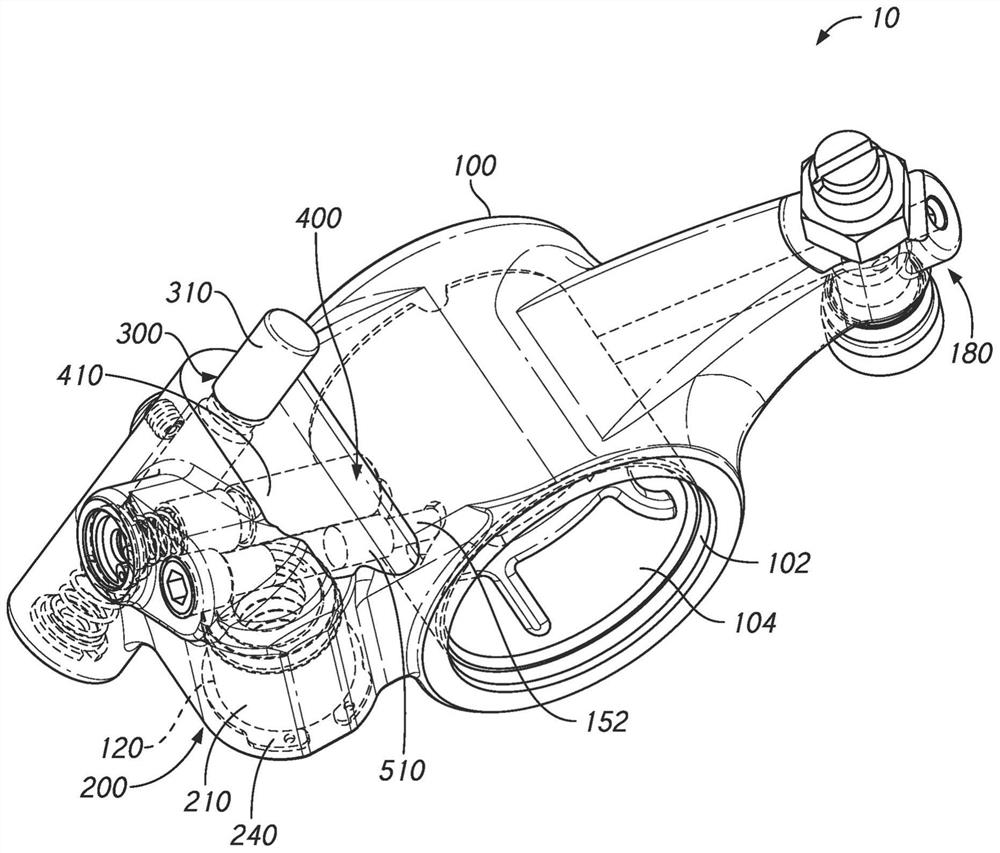

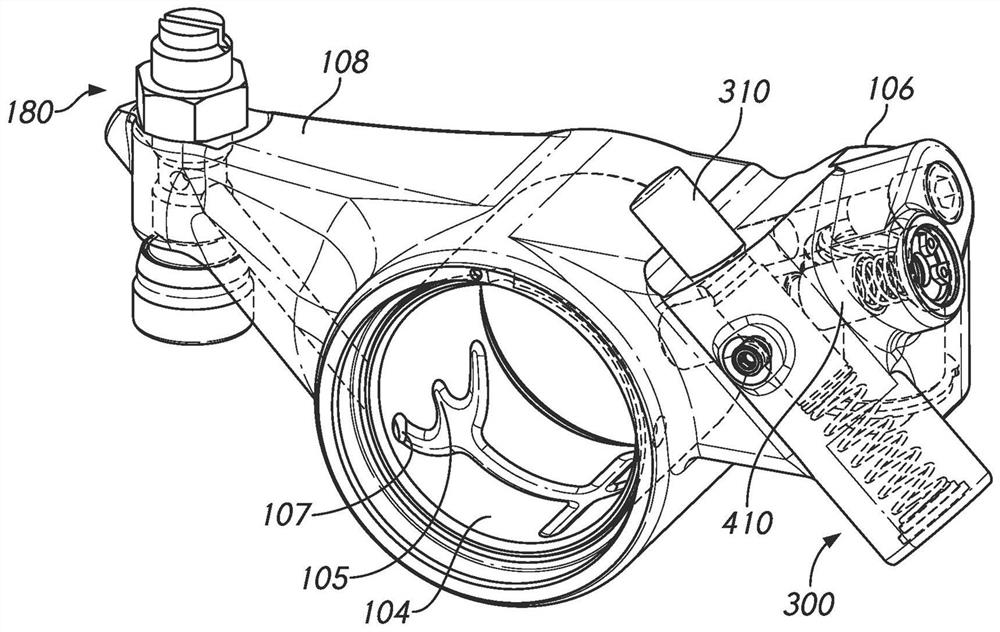

[0043] Figures 1 to 10 A first example valve train assembly in the form of a rocker arm 10 is illustrated in accordance with aspects of the present disclosure. specific reference figure 1 and 2 , the rocker arm 10 may generally comprise a housing or rocker arm body 100 having a central journal portion 102 . A motion receiving portion 106 , which may receive motion from a motion source (ie, a cam), and a motion transmitting end 108 may extend in opposite directions from the central journal portion 102 . The motion transmitting end may contain an adjustable electronic foot or swivel foot assembly 180 for engaging the valve bridge. The motion receiving end 106 may contain the actuator piston assembly 200 housed therein to receive motion from a source of motion through other valve train components such as push rods. According to aspects of the present disclosure, the rocker arm body 100 may house and integrate an actuator piston assembly 200 , a reset piston assembly 300 , an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com