Jig for FPC bare board pasting, and use method thereof

A jig and blank board technology, applied in the field of FPC blank board mounting fixtures, can solve problems such as poor attachment quality, and achieve the effects of ensuring attachment quality, accelerating cleaning speed, and improving cleaning effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

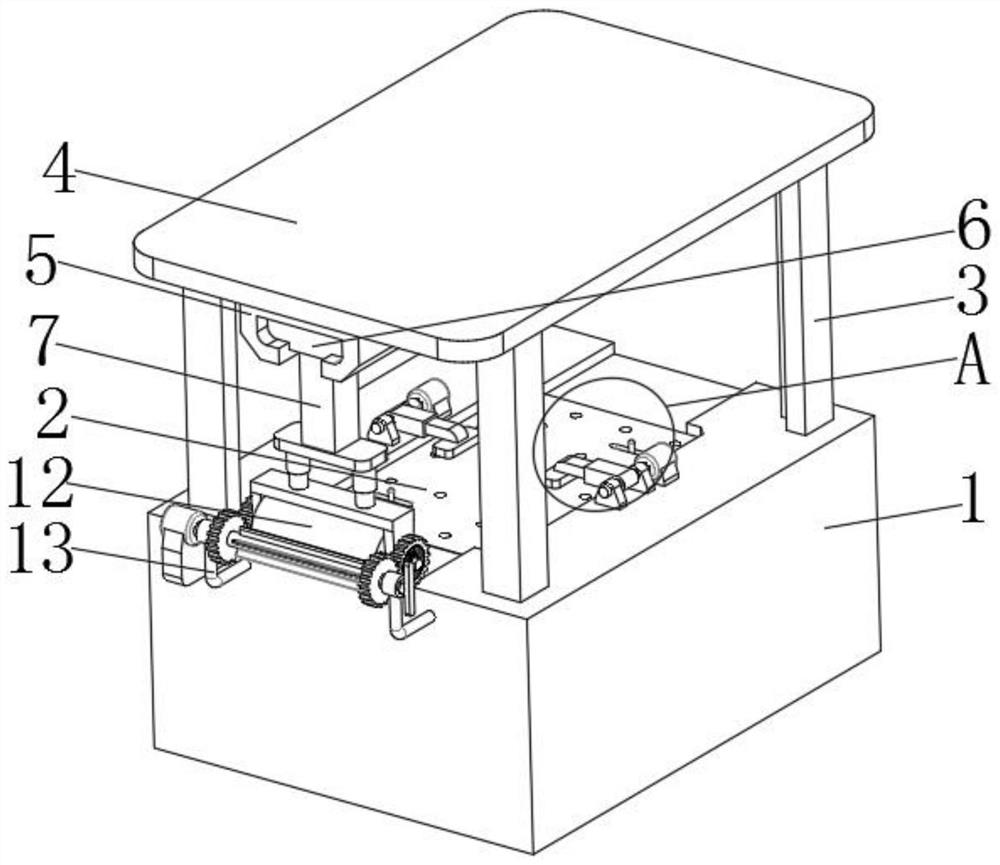

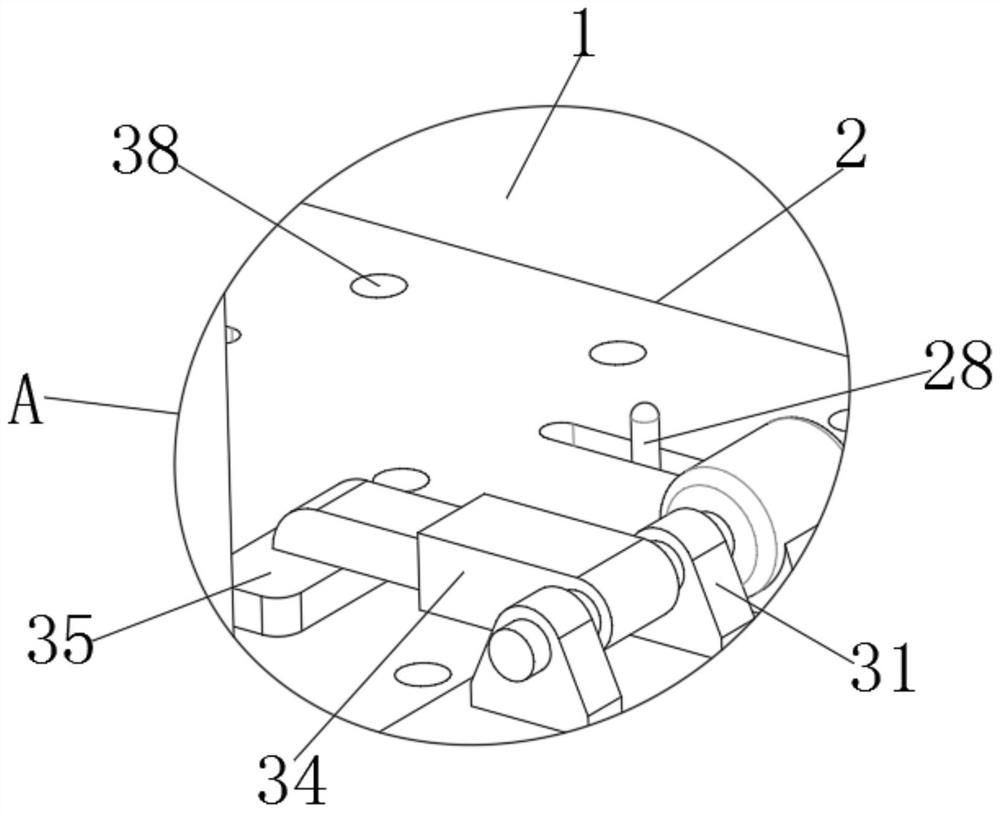

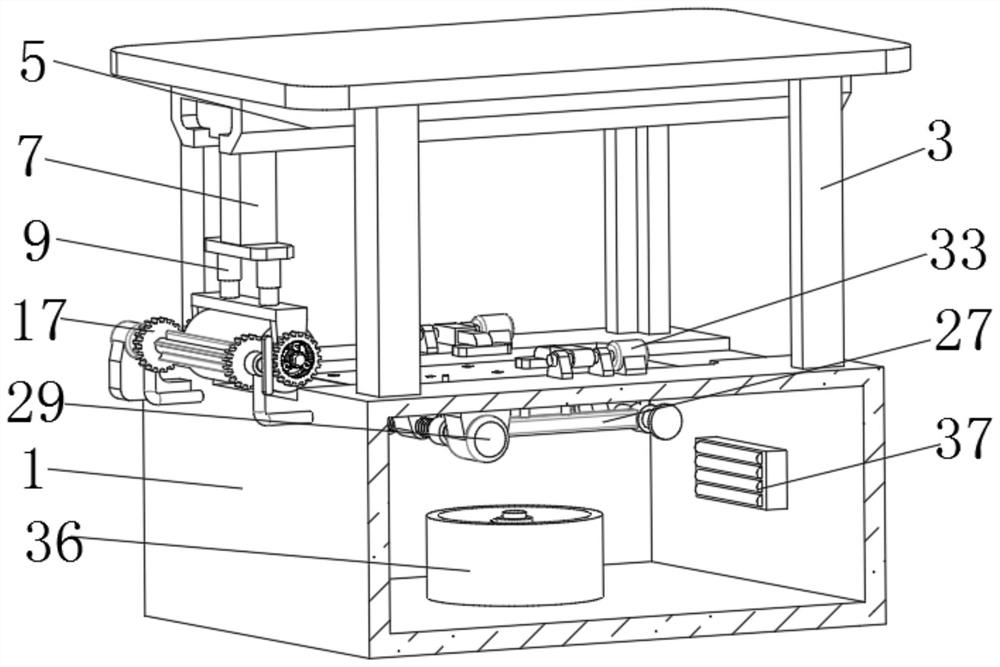

[0044] Example: Reference Figure 1-8 A fixture for FPC empty board attachment is shown, including a fixture bellows 1, an empty board placement groove 2 set on the top of the fixture bellows 1, a slide rail support rod 3 fixedly connected to the top of the fixture bellows 1, Fixedly connected to the slide rail support plate 4 at the top of the four slide rail support rods 3, the bottom of the slide rail support plate 4 is fixedly connected with the transmission slide rail 5, and the transmission slide rail 5 is slidably connected with the transmission slide block 6, and the transmission slide block 6 There is an empty board flattening part for flattening the empty board and having self-cleaning function installed at the bottom of the bottom, the empty board flattening part is connected with the jig bellows 1, and the inside of the jig bellows 1 is installed for auxiliary positioning of the empty board And adjustable empty board positioning part.

[0045] With the above-menti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com