Attaching device, attaching system and attaching method

A sticking and air pressure technology, applied in nonlinear optics, instruments, optics, etc., can solve the problems of affecting the sticking effect, the breakage of the adhesive tape, and the difficulty of product breakage, so as to ensure the quality of the sticker, prevent the The effect of crushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

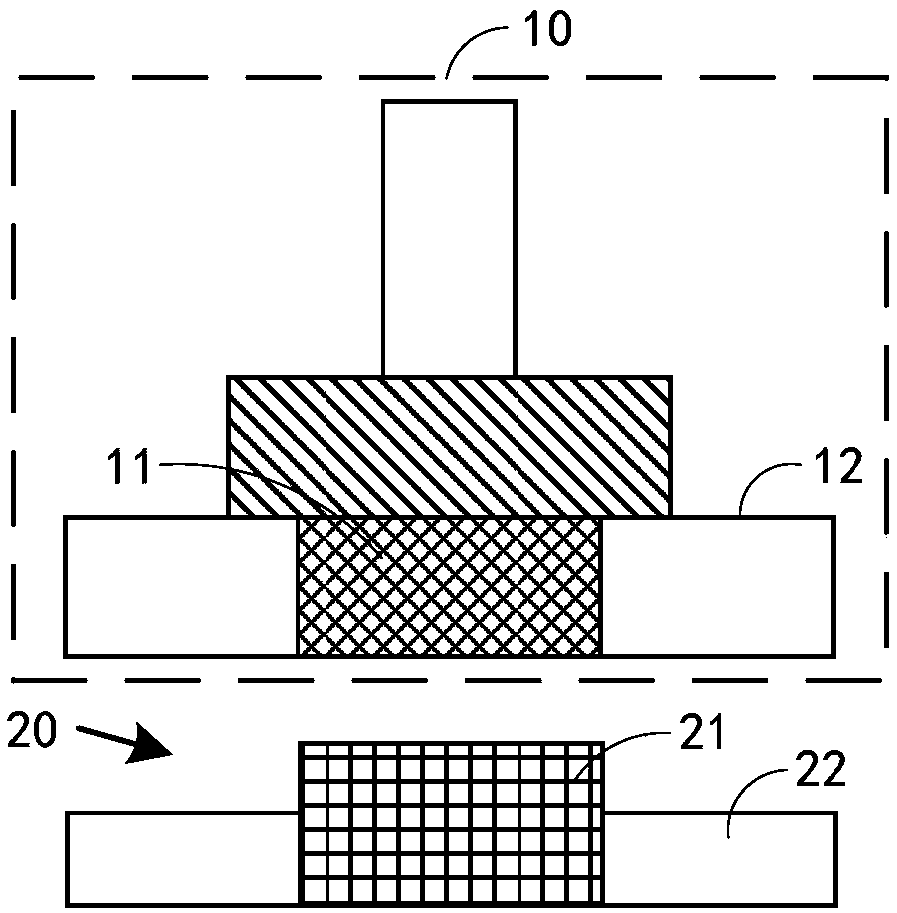

[0027] see figure 2 , is a schematic structural view of the attachment device of the present invention, the attachment device includes: an attachment head 10, and the attachment head 10 includes:

[0028] An indenter unit 11, the indenter unit 11 is made of a soft material, and is used to apply 21 an adhesive force to the first area on the product 20 to be attached;

[0029] The air pressure unit 12 outputs air, and is used to provide air pressure to exert an adhesive force on the second area 22 on the product 20 to be attached.

[0030] In this embodiment, the cross section of the attaching head 10 is circular, and may have other shapes in other embodiments, which are not limited here. Wherein, the air pressure unit 12 is adjacent to the pressure head unit 11 (such as Figure 3a shown); or two air pressure units 12 are respectively arranged on bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com