Sea-island polyphenylene sulfide superfine fiber paper-based battery diaphragm and preparation method thereof

A technology of polyphenylene sulfide and microfiber, which is applied in the direction of secondary batteries, battery pack parts, circuits, etc., can solve the problems of not being suitable for large-scale production, large diaphragm pore size, and technical difficulty, so as to improve the electrolyte Liquid absorption, lower spinning temperature, simple and convenient preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

[0029] Example 1-6 Preparation method of sea-island type polyphenylene sulfide ultrafine fiber paper-based battery separator

[0030] Examples 1-6 are respectively a method for preparing a sea-island type polyphenylene sulfide ultrafine fiber paper-based battery separator. The process parameters during the preparation process are shown in Table 1. The specific preparation process includes the following steps:

[0031] S1. Preparation of polyphenylene sulfide particles: Melt blending and granulating polyphenylene sulfide A with a melt index of 30-120g / 10min and polyphenylene sulfide B with a melt index of 500-2000g / 10min to obtain polyphenylene sulfide Ether particles;

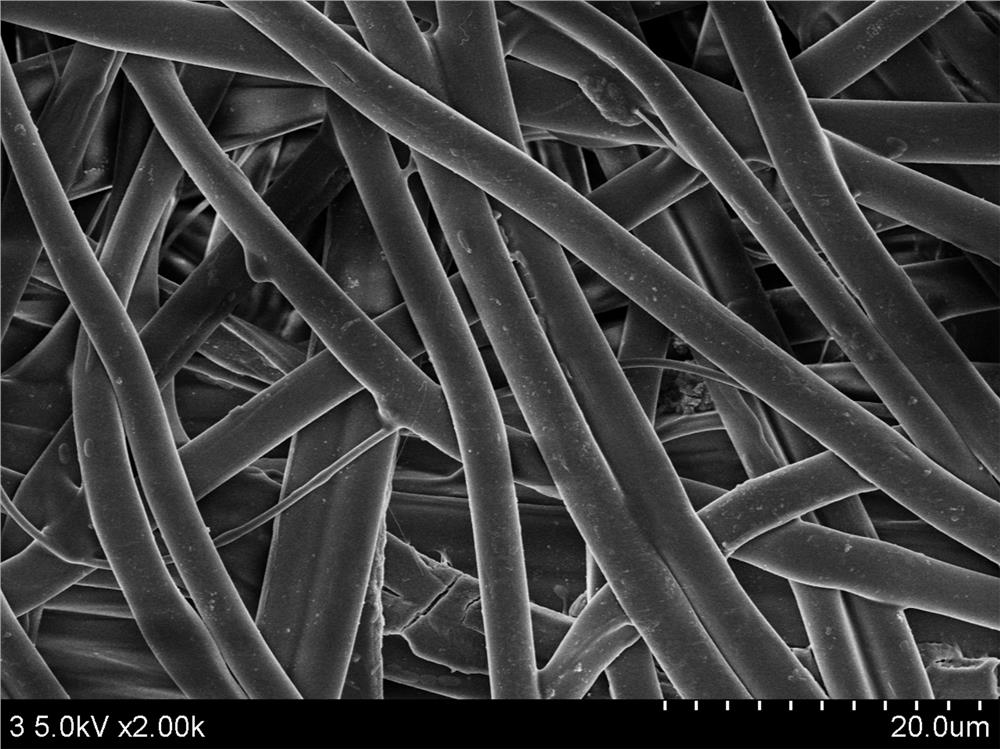

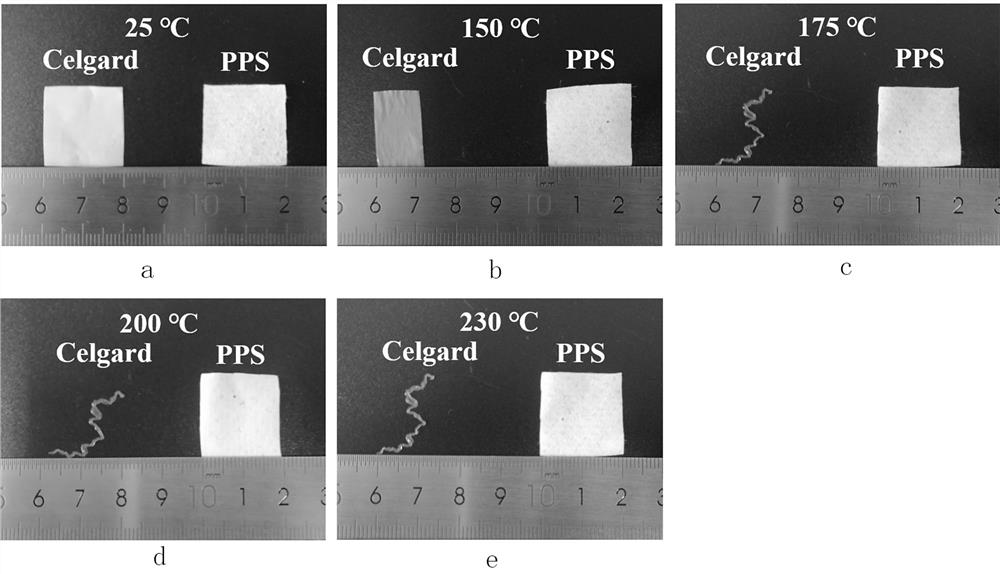

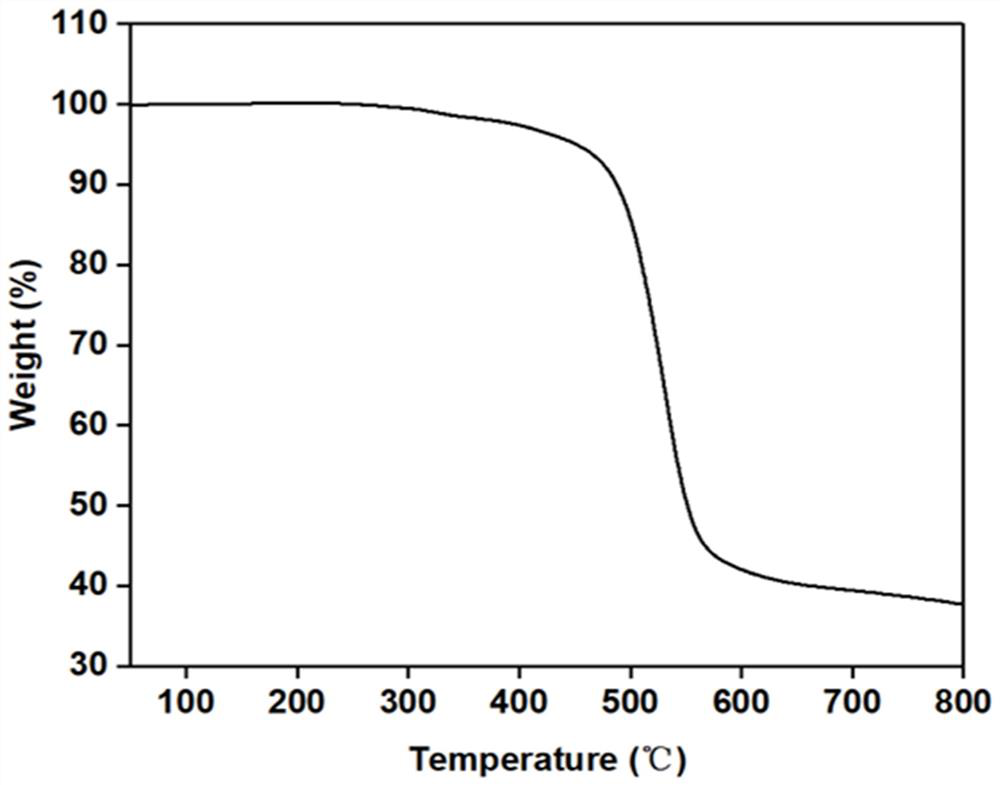

[0032] S2. Preparation of sea-island polyphenylene sulfide composite fibers: dry polyphenylene sulfide particles (PPS) and alkali-soluble polyester (PET) with a melt index of 10-50g / 10min at a drying temperature of 80-160°C , the drying time is 12-24 hours, and then mixed with a mass ratio of 3:7-7:3, and melt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com