Vibrating screen surface dynamic load optimization method

An optimization method and dynamic load technology, applied in the field of vibrating screen and dynamic load optimization of vibrating screen screen surface, can solve the problem of reducing the effective screening area of the screen surface, accelerating the screen surface structure, not reducing the impact of the screen surface, corroding the screen box and vibration isolation. system forces, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

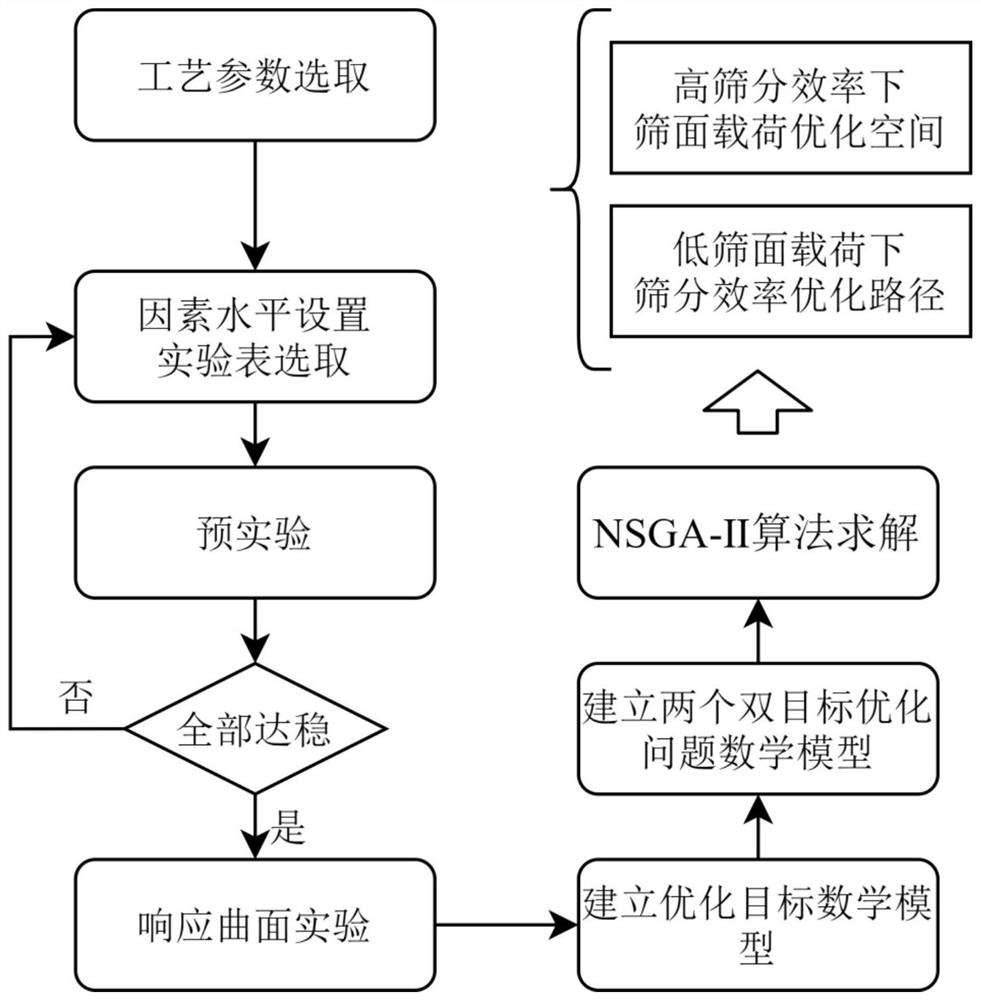

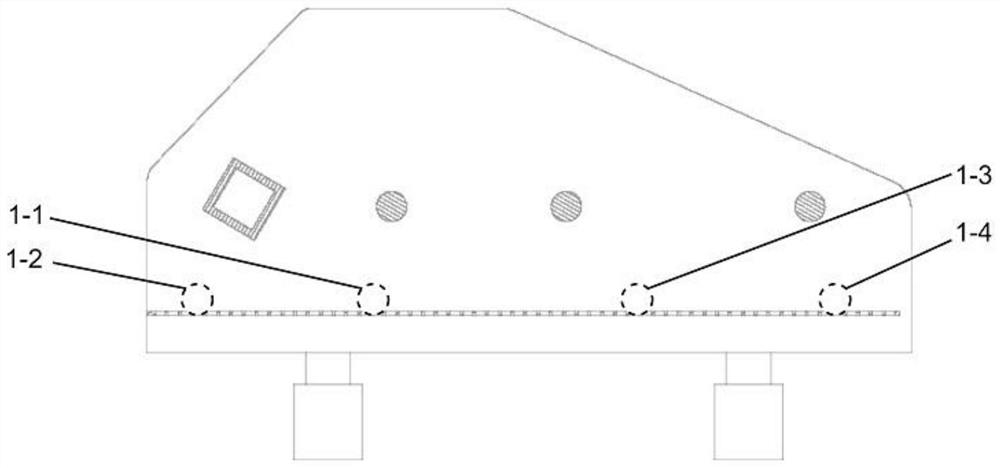

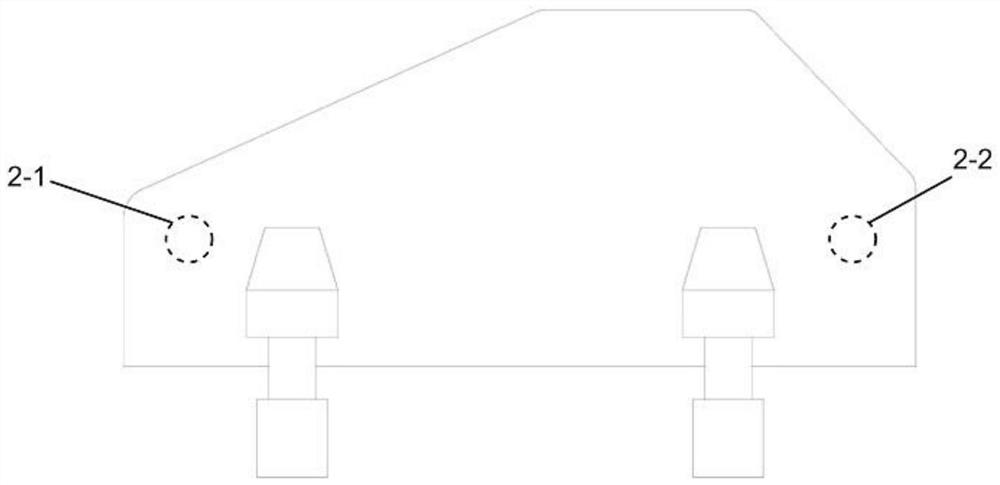

[0098] Such as figure 1 As shown, the invention provides a method for optimizing the dynamic load of the vibrating screen surface. In this embodiment, linear sieves are used for experiments, and the screen surface size of all linear sieves is 2000mm*1300mm, and the inclination angle of the screen surface can be adjusted through the support structure. There are four stress sensors in total, namely the first stress sensor 1-1, the second stress sensor 1-2, the third stress sensor 1-3, and the fourth stress sensor 1-4. figure 2 shown. There are two acceleration sensors, respectively the first acceleration sensor 2-1 and the second acceleration sensor 2-2, and their arrangement positions are as follows: image 3 shown.

[0099] S1: Experiments were carried out with the linear sieve. Select the excitation parameters (amplitude, frequency, vibration direction angle) and the inclination angle of the screen surface as the design variables, and set the feed flow rate to 16t / h. A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com