Display screen quality detection method, terminal and storage medium

A quality inspection method and technology of display screens, which are applied in the direction of testing optical properties, etc., can solve the problem that the shipment of display screens cannot form an effective objective shipment standard, and achieve the effect of improving the quality of shipments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

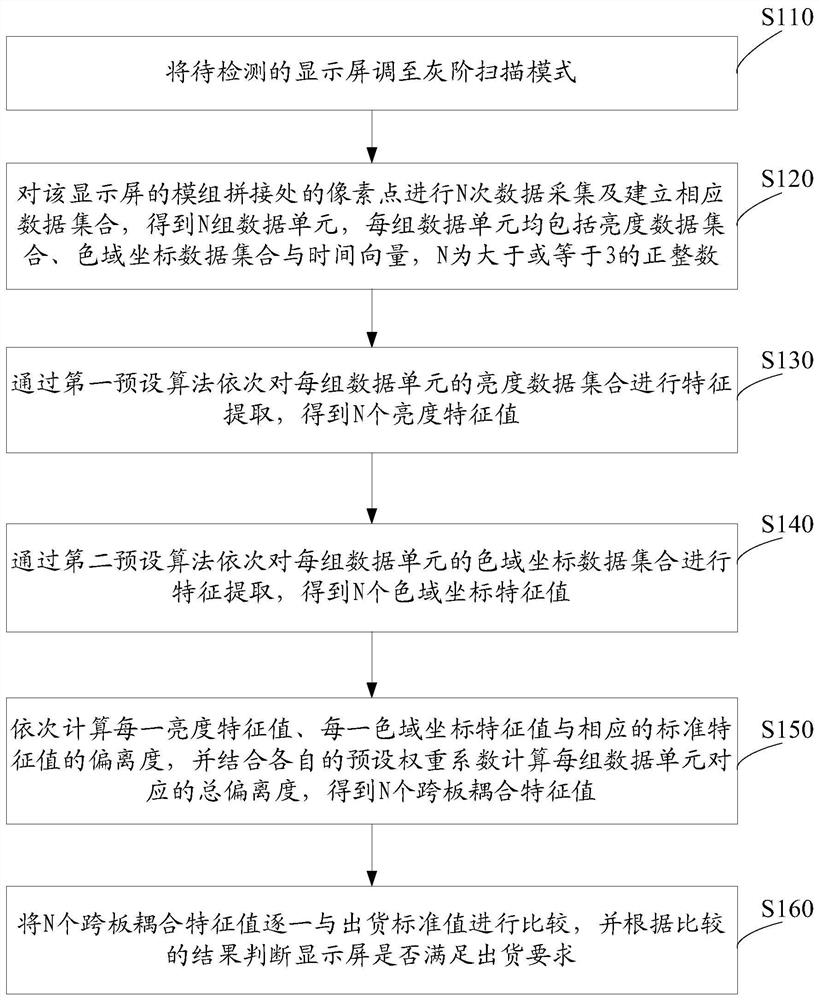

[0025] Such as figure 1 As shown, Embodiment 1 of the present invention provides a method for detecting the quality of a display screen, the method comprising the following steps:

[0026] Step S110: Adjust the display screen to be detected to a grayscale scanning mode.

[0027] Specifically, the display defect due to cross-board coupling mainly refers to the fact that the gray scale of an LED display composed of several lamp boards is discontinuous or uneven due to reasons such as the number of scans or scanning ICs when displaying gray scales. Defects in display effects. Therefore, in order to realize the corresponding display defect detection in the quality inspection method of the display screen according to the embodiment of the present invention, it is first necessary to adjust the display screen to be inspected to the grayscale scanning mode, so as to perform the corresponding display defect detection operation subsequently.

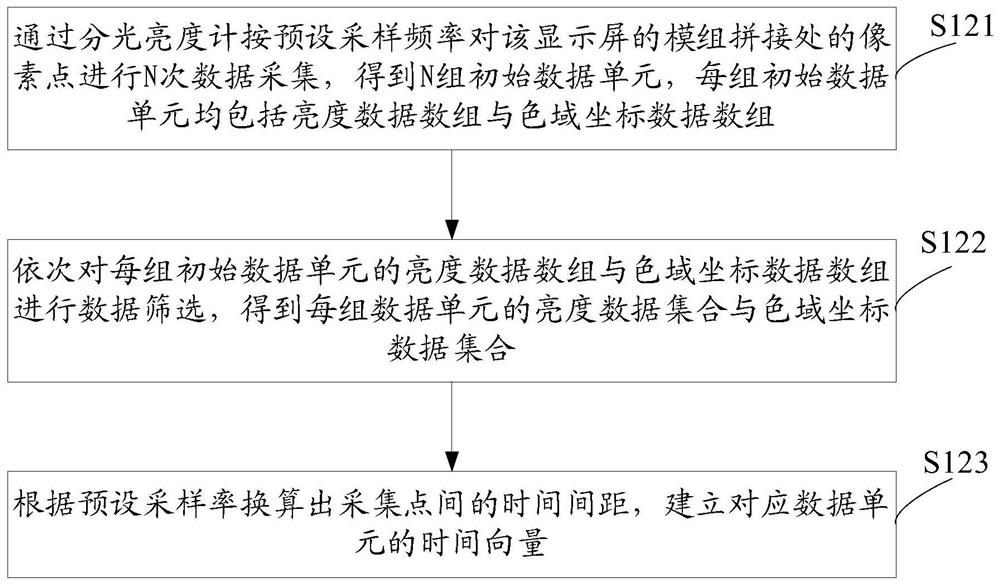

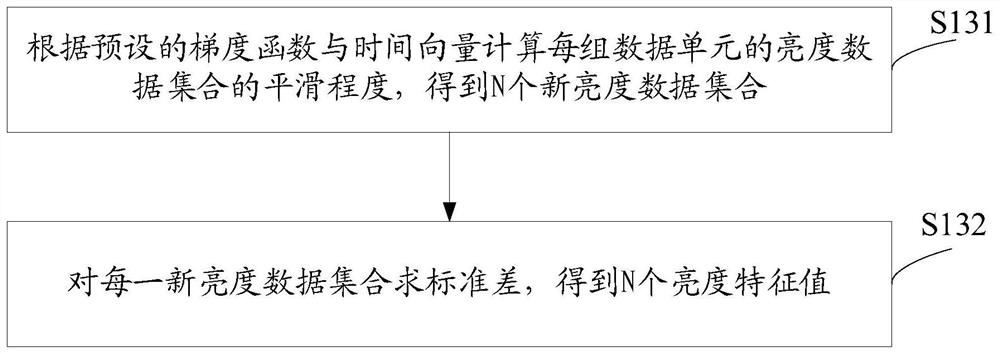

[0028] Step S120: Perform N times of data...

Embodiment 2

[0054] Such as Figure 7As shown, Embodiment 2 of the present invention proposes a terminal 20, the terminal 20 includes a display screen 21, a memory 22, a processor 23, a program stored in the memory 22 and operable on the processor 23, and a program for implementing the processor 23 and the data bus 24 for connection and communication between the memory 22 and the display screen 21 respectively, when the program is executed by the processor, to realize the steps of the quality detection method of the display screen in the first embodiment above, specifically as described above, here I won't repeat them here.

[0055] It should be noted that the embodiment of the terminal 20 in the embodiment of the present invention belongs to the same idea as the method embodiment 1 or the method embodiment 2, and its specific implementation process is detailed in the method embodiment 1, and the technical features in the method embodiment 1 are in the terminal 20 embodiments are correspo...

Embodiment 3

[0057] Embodiment 3 of the present invention proposes a storage medium for computer-readable storage. The storage medium stores one or more programs, and the one or more programs can be executed by one or more processors to implement the above-mentioned embodiments. The invention relates to specific steps of a quality detection method for a display screen.

[0058] It should be noted that the above-mentioned storage medium and the method embodiment 1 belong to the same concept, and the specific implementation process is detailed in the method embodiment 1, and the technical features in the method embodiment 1 are correspondingly applicable in the storage medium embodiment, and are not repeated here. repeat.

[0059] The quality inspection method, terminal, and storage medium of the display screen in the embodiment of the present invention, when each display screen is tested before shipment, the display screen to be tested is first adjusted to the grayscale scanning mode, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com