Reflection type spiral optical fiber liquid level sensor

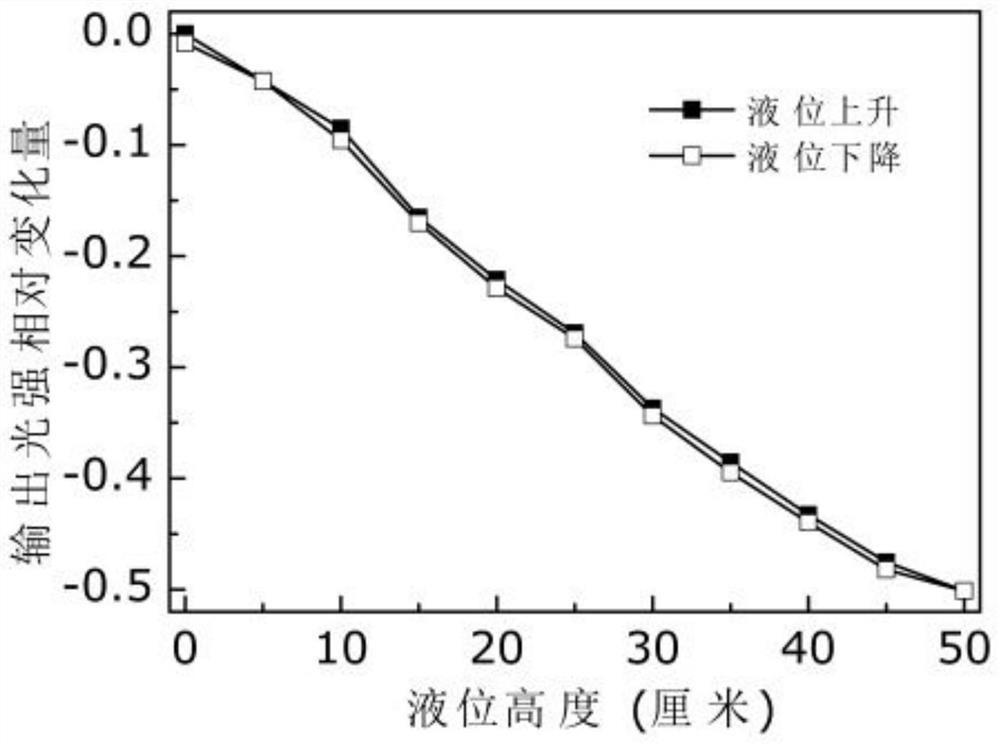

A liquid level sensor, spiral-shaped technology, applied in the field of sensors, can solve the problems of reducing the mechanical properties and service life of optical fibers, poor repeatability of sensor measurement results, and changes in optical transmission characteristics of optical fibers, achieving no measurement blind spots, high accuracy, and resolution high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

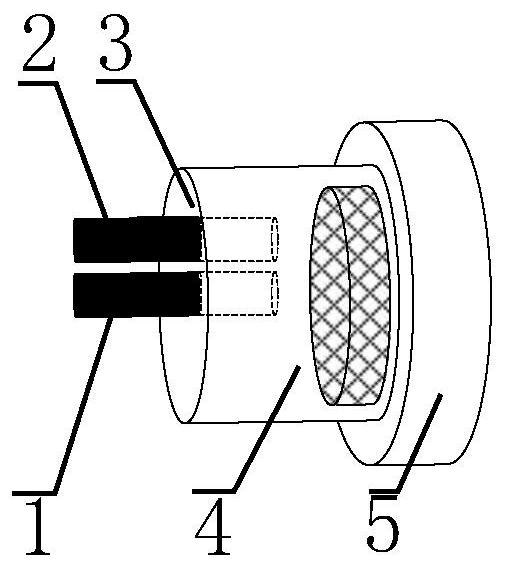

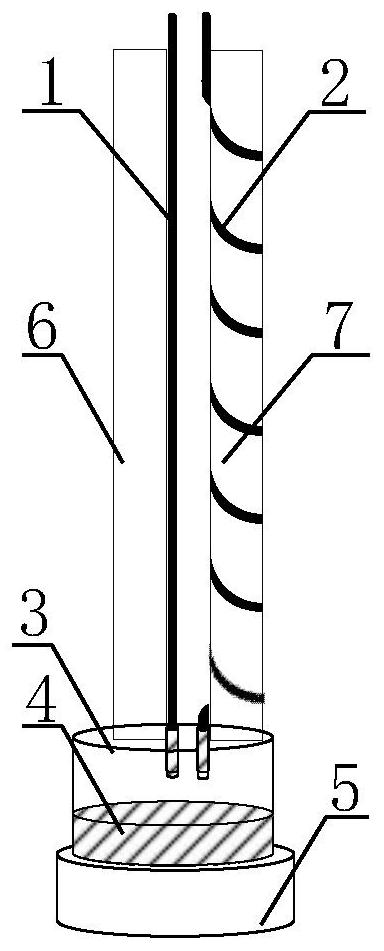

[0018] see figure 1 , figure 2 , a reflective spiral optical fiber liquid level sensor, comprising a sensor holder, a receiving optical fiber 1, several incident optical fibers 2 and a concave reflector 4; the incident optical fiber 2 is helical, and the pitch and helical diameter can be determined as required; The upper part of the sensor fixing seat is a solid body 3, and the lower part of the sensor fixing seat is a hollow body 5. The center of the solid body is provided with a receiving fiber installation hole along the axial direction, and is evenly arranged circumferentially outside the receiving fiber installation hole. Several incident optical fiber installation holes, the rear end of the receiving optical fiber 1 and the rear ends of all incident optical fibers respectively enter the hollow body of the sensor holder through the receiving optical fiber installation hole and the incident optical fiber installation hole;

[0019] A concave reflector 4 is arranged in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com