Dry-mixed mortar production raw material drying and screening treatment system

A dry-mixed mortar and processing system technology, applied in the directions of sand drying, drying solid materials, drying gas arrangement, etc., can solve the problems of fast falling speed of production raw materials, easy accumulation of raw materials, and inability to fully dry raw materials, etc., to increase retention. time, increase drying time, better drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways as defined and covered by the claims.

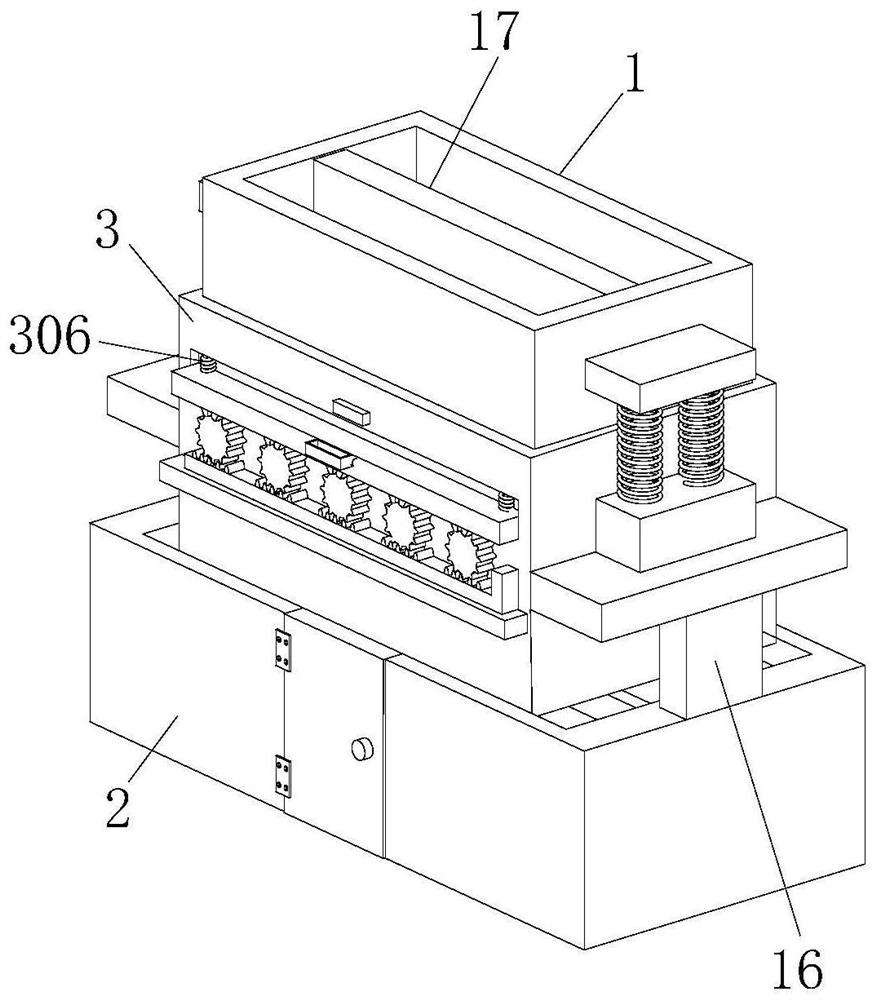

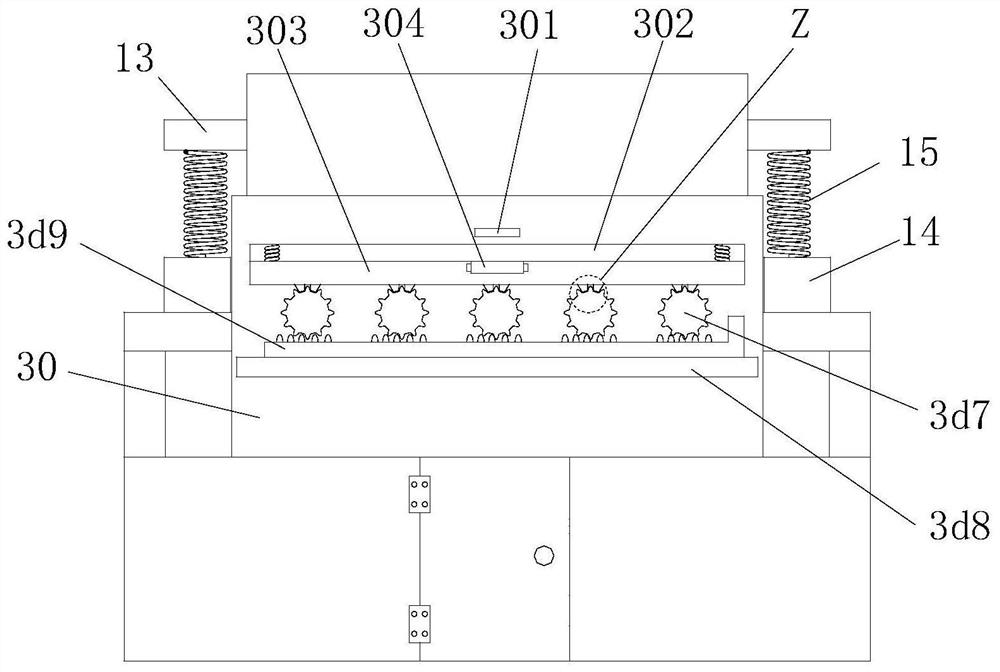

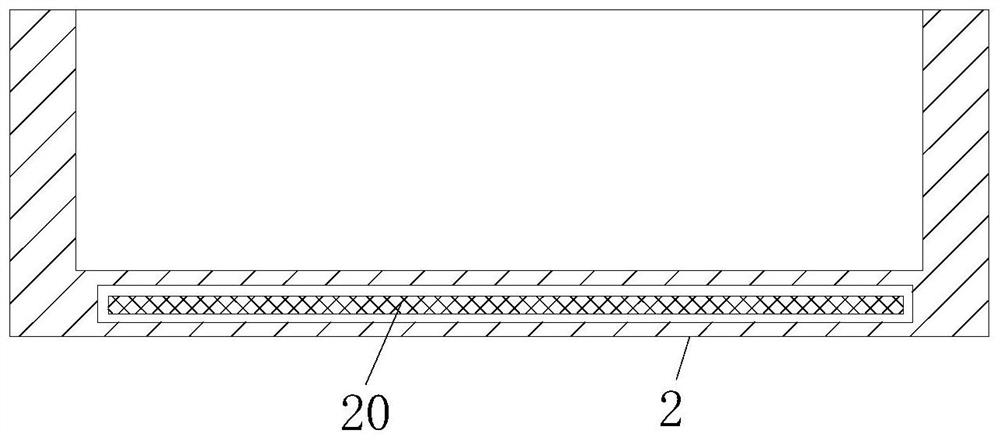

[0036] like Figure 1 to Figure 13 As shown, a dry-mixed mortar production raw material drying and screening treatment system includes a sieving box 1, a collection box 2 and a drying device 3, and a collection box 2 is arranged directly below the screening box 1, and the collection The lower end of the box 2 is connected to the existing ground, and a drying device 3 is arranged between the upper end of the collecting box 2 and the lower end of the screening box 1 .

[0037] The lower end of the sieve box 1 is uniformly provided with a circular through groove, a screen 11 is installed in the circular through trough, a vibrating motor 12 is installed at the rear end of the sieve material box 1, and the left and right sides of the sieve material bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com