Burner and baking equipment comprising same

A burner and combustion chamber technology, which is applied in the field of tobacco leaf baking and agricultural machinery, can solve the problems of short service life, easy failure, accumulation, etc., achieve short troubleshooting time, ensure heating demand, and simple overall structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

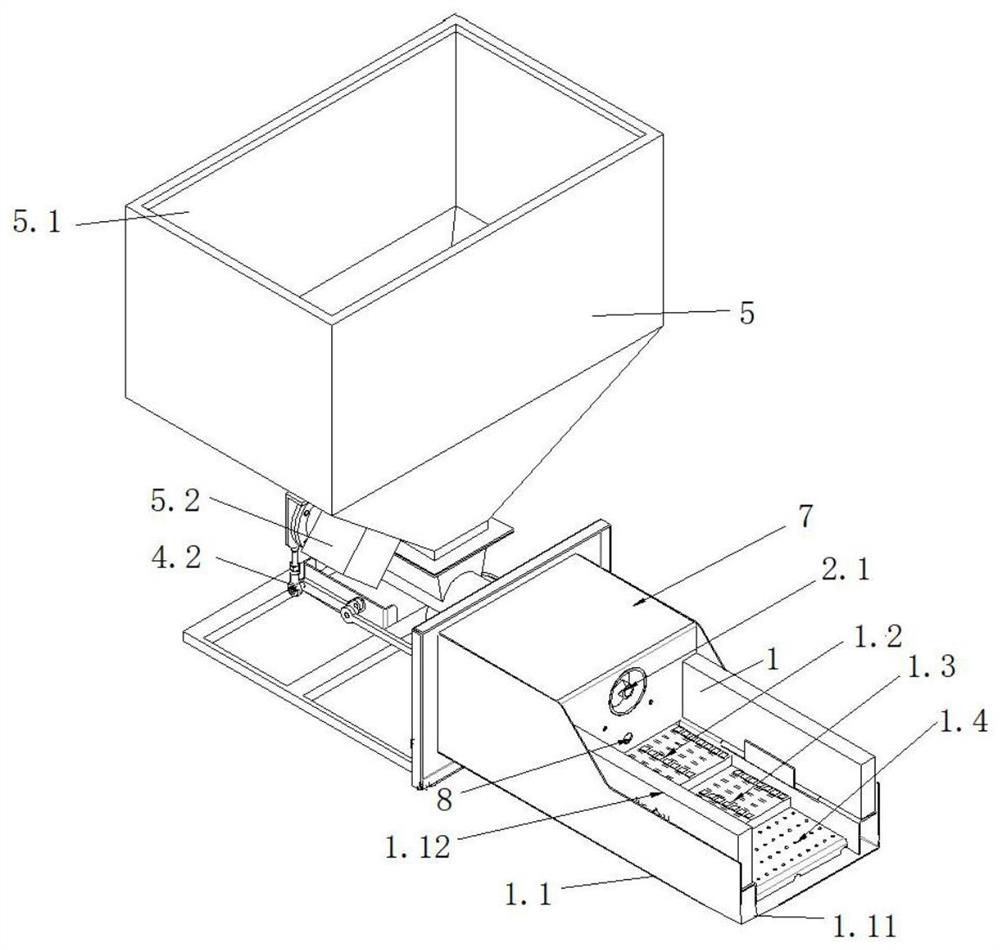

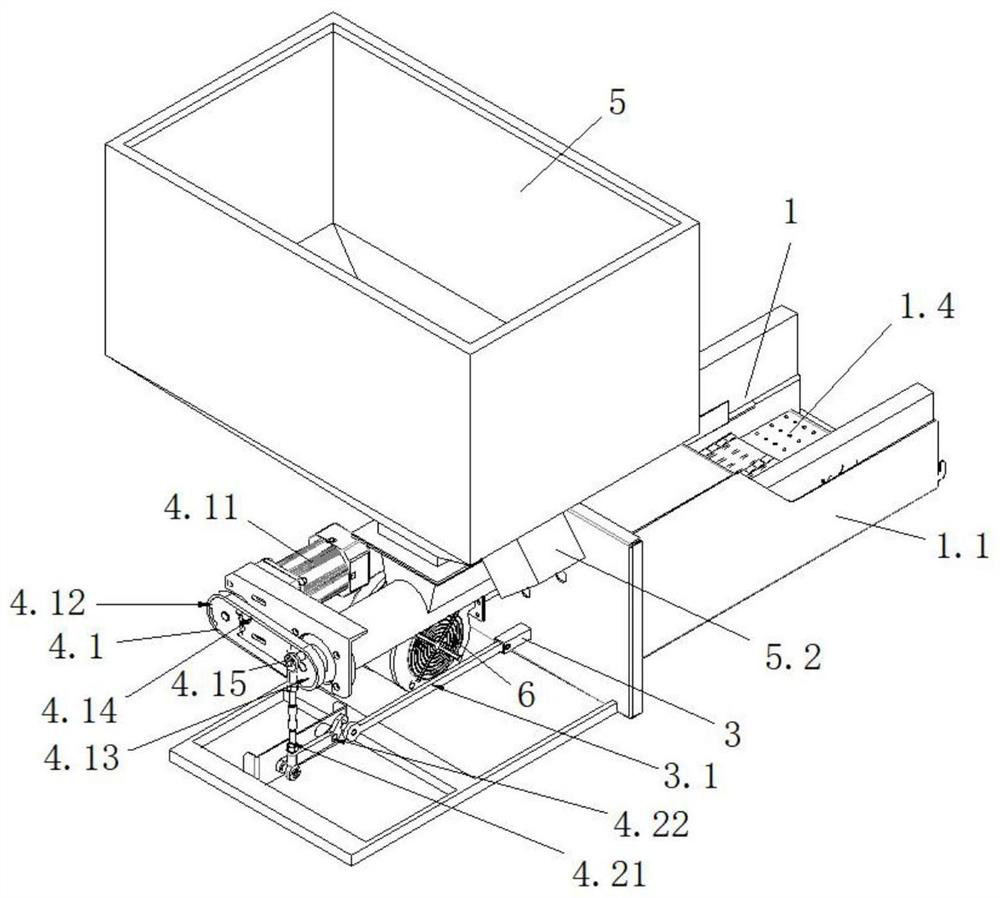

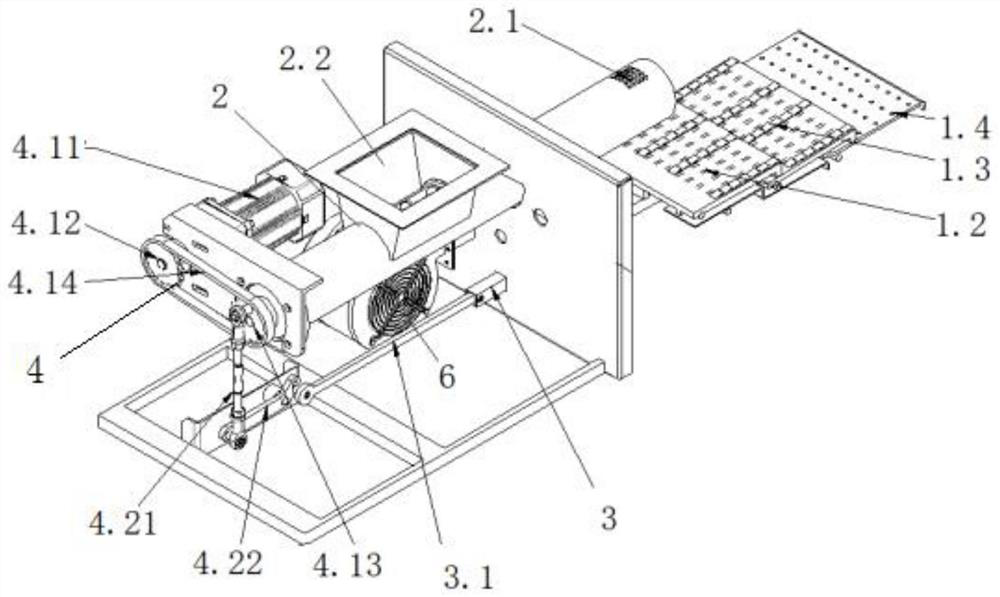

[0038] see Figure 1-Figure 4 , the present embodiment provides a burner, which includes a combustion chamber 1, a feeding mechanism 2, a decoking mechanism 3 and a power assembly 4, and the detailed structure is as follows:

[0039] The combustion chamber 1 includes an installation frame 1.1 and a combustion panel group, where the installation frame 1.1 is a combustion space with a U-shaped structure formed by the installation bottom plate 1.11 and the baffle plate 1.12; the combustion panel group includes a first movable panel 1.2, a fixed The plate 1.3 and the second movable plate 1.4, the fixed plate 1.3 is fixedly arranged on the installation frame 1.1 for fuel combustion to form a combustion flame, the first movable plate 1.2, the fixed plate 1.3 and the second movable plate 1.4 along the fuel delivery direction They are arranged in sequence, and both the first movable plate 1.2 and the second movable plate 1.4 can move relative to the fixed plate 1.3 along the fuel deli...

Embodiment 2

[0047] This embodiment discloses a roasting device, which includes a roasting chamber and a burner as in Embodiment 1 that provides heat for the roasting chamber.

[0048] The burner in this embodiment is a built-in burner, and the combustion chamber 1 of the burner is located inside the baking chamber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com