Cavity assembled lamp

An assembled, cavity technology, applied in lighting devices, gas/waterproof devices, components of lighting devices, etc., can solve the problems of high cost, low production efficiency, and high risk of waterproof failure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

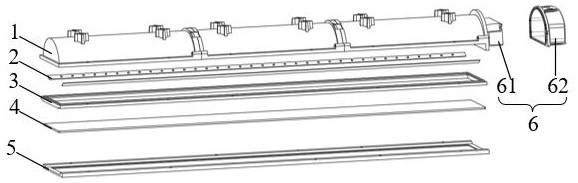

[0027] Please see attached Figures 1 to 3 , a cavity assembled lamp, comprising: a cavity 1, an aluminum substrate 2, a support plate 3, a glass 4 and an upper cover plate 5, the upper cover plate 5 and the support plate 3 are fixedly combined by bolt fasteners , to provide a frame fixing structure for the glass 4. After the upper cover plate 5, the glass 4 and the support plate 3 are assembled into one arrangement, they are fixed on the cavity 1 by the bolt fasteners. The aluminum substrate 2 is fixedly mounted on the support plate 3 at a certain inclination angle. The light-emitting surface of the aluminum substrate 2 faces the cavity 1, the aluminum substrate 2, the support plate 3, the glass 4 and the upper cover The length of the plate 5 matches the length of the cavity 1 .

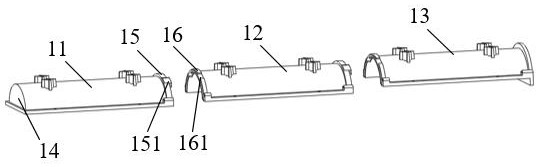

[0028] Further, the cavity 1 is composed of a cavity tail 11 , a cavity middle 12 and a cavity head 13 , the ends of the cavity tail 11 and the cavity head 13 away from the cavity middle 12 . The ...

Embodiment 2

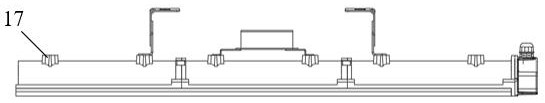

[0038] Please see attached figure 1 , with Figure 4 and attached Figure 5 , a cavity assembled lamp, comprising: a cavity 1, an aluminum base plate 2, a support plate 3, a glass 4 and an upper cover plate 5, the support plate 3 is nested into the upper cover plate 5 and then snapped The structure fixes the upper cover plate 5 on the cavity 1, the nesting structure of the upper cover plate 5 and the support plate 3 provides a frame fixing structure for the glass 4, and the aluminum substrate 2 has a certain structure. The inclination angle is fixed on the support plate 3, the light-emitting surface of the aluminum substrate 2 faces the cavity 1, the length of the aluminum substrate 2, the support plate 3, the glass 4 and the upper cover plate 5 is the same as that of the cavity. Body 1 matches the length.

[0039] Further, the cavity 1 is composed of a cavity end cover 18 , a cavity component 19 and an adapter block 7 .

[0040] Further, a third reinforcing rib 191 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com