N-decylamine phosphate salt ionic liquid, preparation method and application thereof

A technology of n-decylamine phosphate and ionic liquid, which is applied in the preparation of amino compounds from amines, chemical instruments and methods, recycling technology, etc., and can solve the problems of the volatility and toxicity of organic extractants, the difficulty of post-processing, and the impact on the environment and human body and other issues, to achieve sustainable development, good industrial application prospects, and overcome volatile effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The present invention also provides a preparation method of the above-mentioned n-decylamine phosphate salt ionic liquid, comprising the following steps:

[0033] (1) decylamine and P507 are respectively dissolved in the same solvent and dissolved to obtain a concentration of decylamine solution of 10mmol / L and a concentration of 10mmol / L of P507 solution; the solvent can be well known to those skilled in the art A solvent, preferably toluene, dichloromethane or sherwood oil;

[0034] (2) The n-decylamine solution and the P507 solution are mixed for reaction, and the temperature is 80-120° C. for 50-180 minutes. After the reaction is completed, the n-decylamine phosphate salt ionic liquid crude product is obtained; n-decylamine The molar ratio with P507 is 1.1:1~2;

[0035] The specific reaction is as follows:

[0036]

[0037] (3) The crude product of n-decylamine phosphate salt ionic liquid obtained in step (2) is extracted successively with the extractant ethyl ...

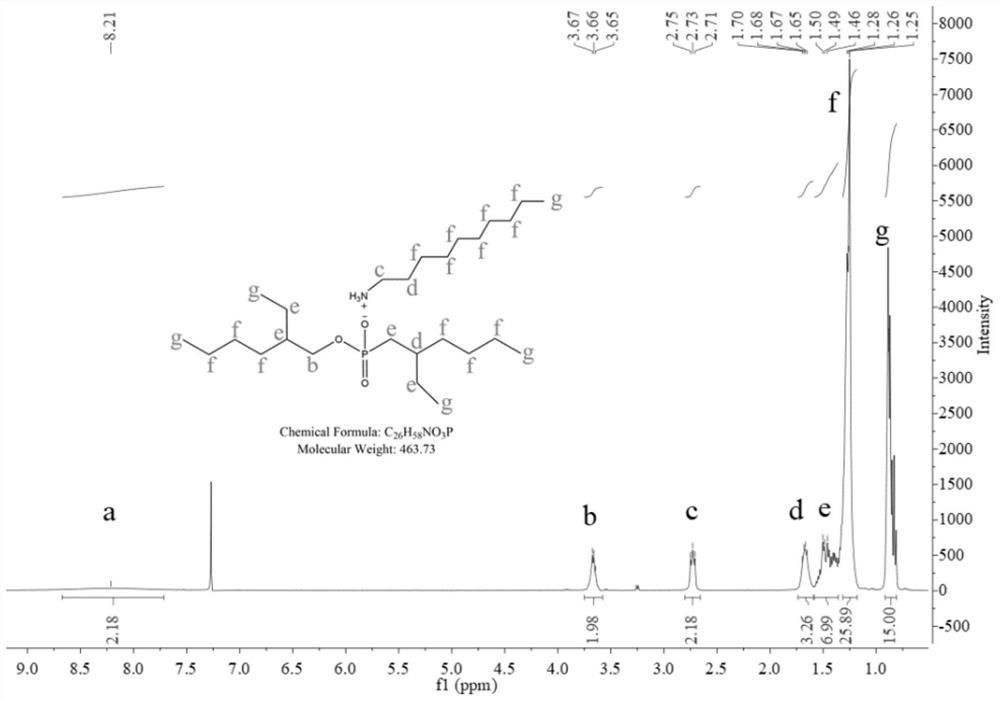

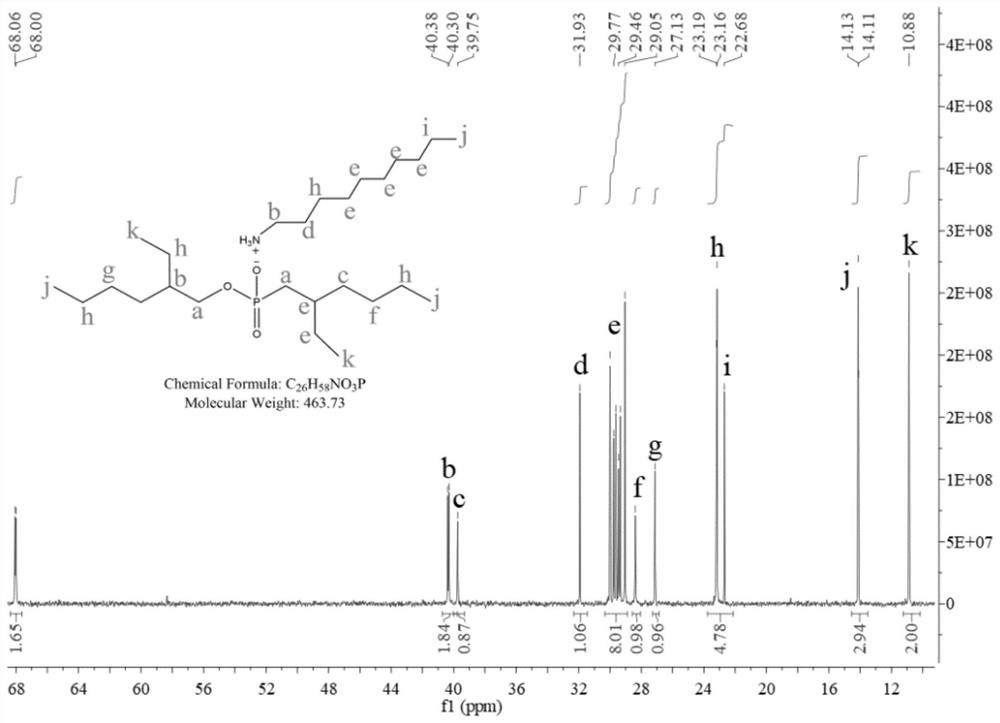

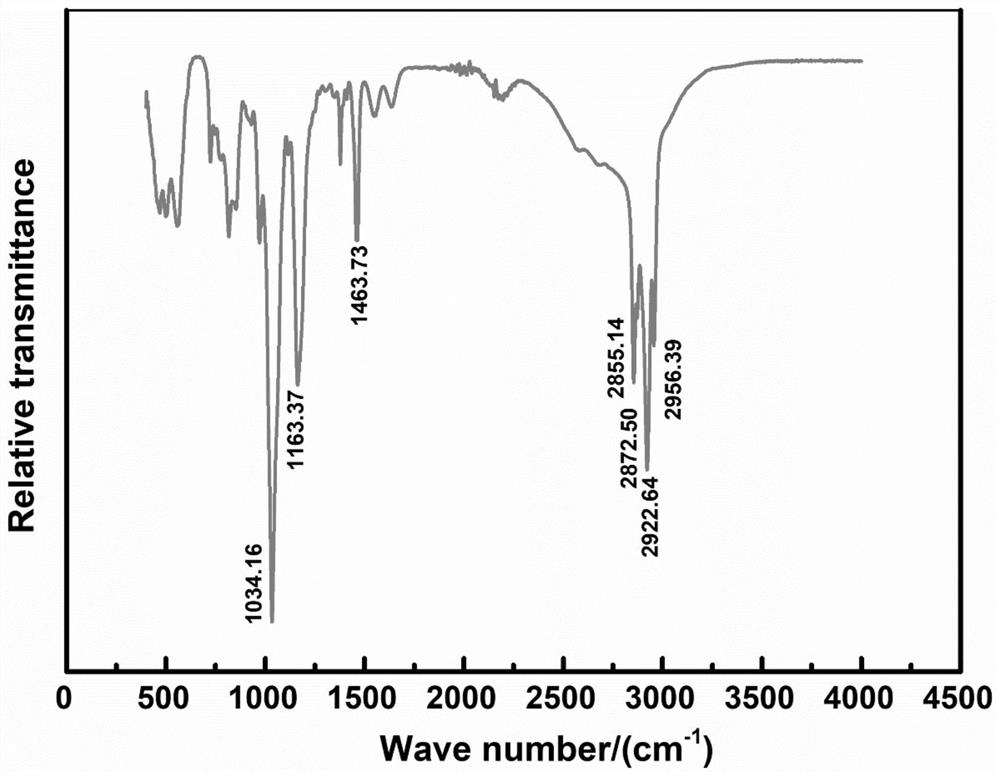

Embodiment 1

[0042] A kind of n-decylamine phosphate ester salt ionic liquid preparation method, comprises the following steps:

[0043] (1) Dissolve n-decylamine (1.66g, 11mmol) and P507 (3.09g, 10mmol) in 20mL of absolute ethanol, respectively;

[0044] (2) Pour the dehydrated ethanol solution dissolved with P507 into the three-necked flask, then use a constant pressure funnel to slowly add the dehydrated ethanol solution dissolved with n-decylamine into the three-necked flask, and completely pour the n-decylamine into the three-necked flask within 15 minutes In the flask, the reaction was continued for 120 min. After the reaction is completed, the crude product of n-decylamine phosphate ester salt ionic liquid is obtained; the reaction temperature of n-decylamine and P507 is 89° C.;

[0045] (3) the n-decylamine phosphate salt ionic liquid crude product that step (2) obtains adopts extraction agent ethyl acetate to extract, separates the upper organic phase, and organic phase is separa...

Embodiment 2

[0052] A kind of n-decylamine phosphate ester salt ionic liquid preparation method, comprises the following steps:

[0053] (1) Dissolve n-decylamine (11mmol) and P507 (15mmol) in 22mL of absolute ethanol respectively;

[0054] (2) Pour the dehydrated ethanol solution dissolved with P507 into the three-necked flask, then slowly add the dehydrated ethanol solution dissolved with decylamine into the three-necked flask using a constant pressure funnel, and pour the decanylamine into the three-necked flask completely within 15 minutes. In the flask, the reaction continued for 130 minutes. After the reaction was completed, the crude product of n-decylamine phosphate ester salt ionic liquid was obtained; the reaction temperature of n-decylamine and P507 was 95°C;

[0055] (3) the n-decylamine phosphate salt ionic liquid crude product that step (2) obtains adopts extraction agent ethyl acetate to extract, separates the upper organic phase, and the organic phase is separated by column...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com