Method for extracting quebrachitol from artemisia plants by using water as extraction solvent

A kind of technology of Quina bark alcohol and Artemisia plants, applied in the field of separation and purification of plant components, to achieve the effect of simple and easy decolorization process, high yield and wide source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

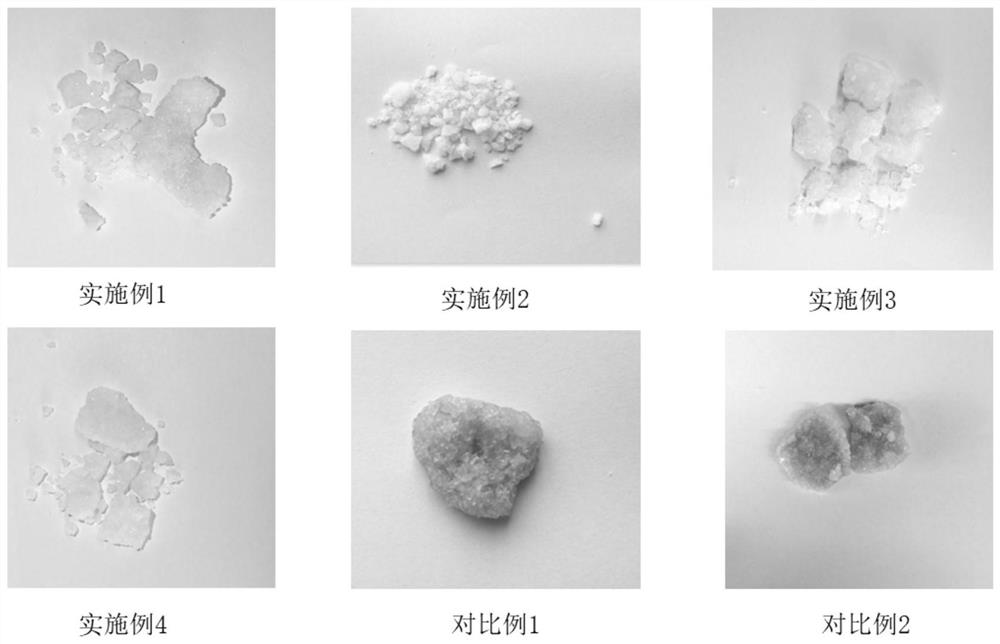

Embodiment 1

[0026] Take 8 kg of crushed Artemisia annua medicinal materials, add 160 kg of pure water, mix well, condense and reflux at 60°C for 3 times, extract for 2 hours each time, combine the extracts, and add 1.0% of the total mass of the extracts to the extracts Chitosan flocculant, after 3 hours of static flocculation, filter to remove impurities to obtain a decolorized extract; the decolorized extract passes through D101 macroporous resin at a flow rate of 1.5BV / h, collects the effluent and concentrates it under reduced pressure at 70°C Obtain 912g of crude extract, add 2.5L of 60% ethanol solution to the crude extract to dissolve it, crystallize at normal temperature, then use 2L of 60% ethanol solution to completely dissolve the crystal, and recrystallize at normal temperature , Obtain 367g of Quaia cortisol crystals.

Embodiment 2

[0028] Take 8kg of crushed Artemisia annua medicinal materials, add 120kg of pure water, mix well, condense and reflux at 70°C and extract for 3 times, extract for 2 hours each time, combine the extracts, and add 0.5% of the total mass of the extracts to the extracts Chitosan flocculant, after static flocculation for 3 hours, filtered to remove impurities, the filtered solution passed through D101 macroporous resin at a flow rate of 1.5BV / h, and the effluent was collected and concentrated under reduced pressure at 70°C to obtain 998g rough soak paste, add 3L of ethanol solution with a volume fraction of 60% to the crude extract to dissolve it, crystallize at room temperature, then use 2L of ethanol solution with a volume fraction of 50% to completely dissolve the crystals, and place it at room temperature for recrystallization , Obtain 351g of Quaia cortisol crystals.

Embodiment 3

[0030] Take 8 kg of crushed Artemisia annua medicinal material, add 200 kg of tap water, mix well, condense and reflux at 75°C and extract for 3 times, extract for 2 hours each time, combine the extracts, and add 1.5% of the total mass of the extract to the extract Chitosan flocculant, after standing for flocculation for 4 hours, filter to remove impurities, the filtered solution passes through D101 macroporous resin at a flow rate of 1.3BV / h, collect the effluent and concentrate under reduced pressure at 65°C to obtain 893g crude extract 1.5 L of ethanol solution with a volume fraction of 60% was added to the crude extract to dissolve it, placed at room temperature for crystallization, and then 2.5 L of ethanol solution with a volume fraction of 55% was used to completely dissolve the crystals, and placed at room temperature for recrystallization. Crystallized to obtain 392 g of quinia cortisol crystals.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com