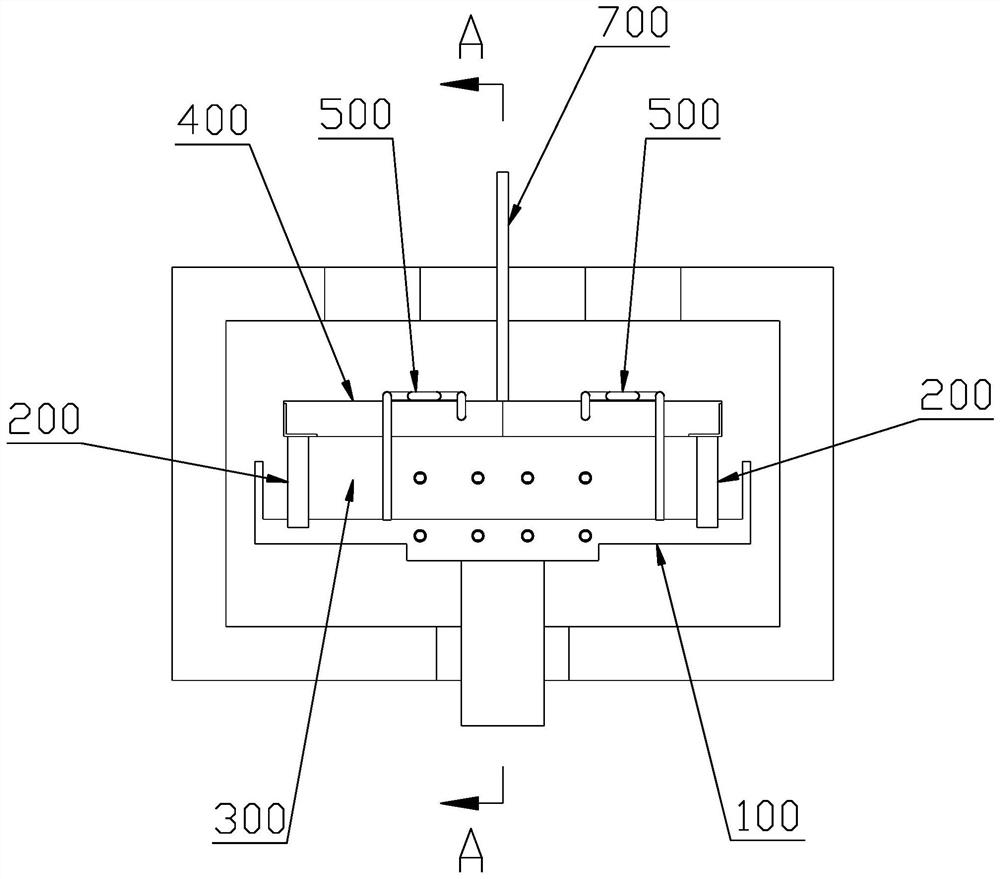

Glass forming device and forming method for large-diameter neodymium-doped phosphate laser glass

A glass forming, neodymium phosphate technology, applied in glass forming, glass manufacturing equipment, manufacturing tools, etc., can solve problems such as glass surface cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] A large-diameter neodymium-doped phosphate laser glass is formed, and the process is as follows:

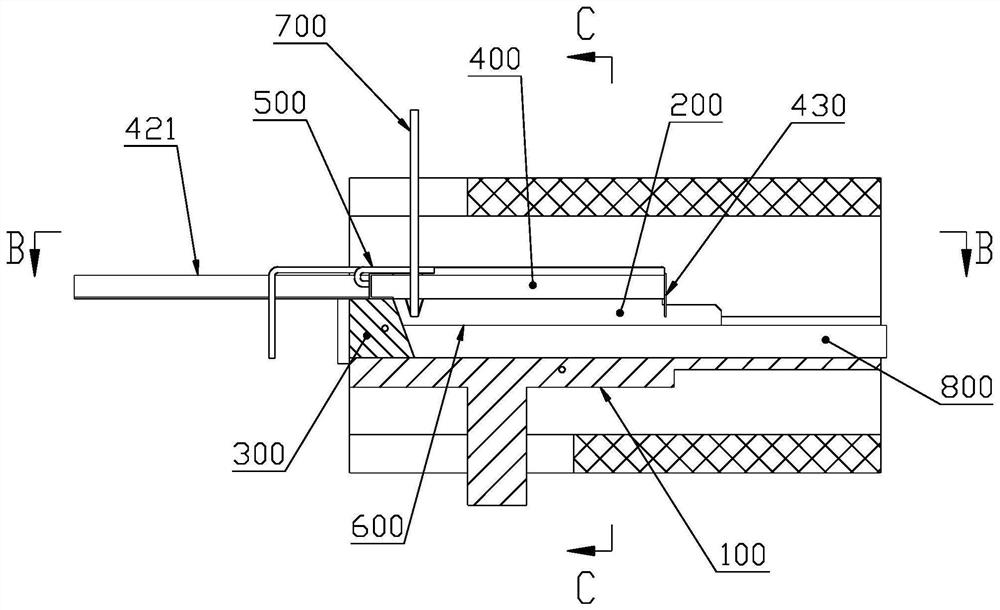

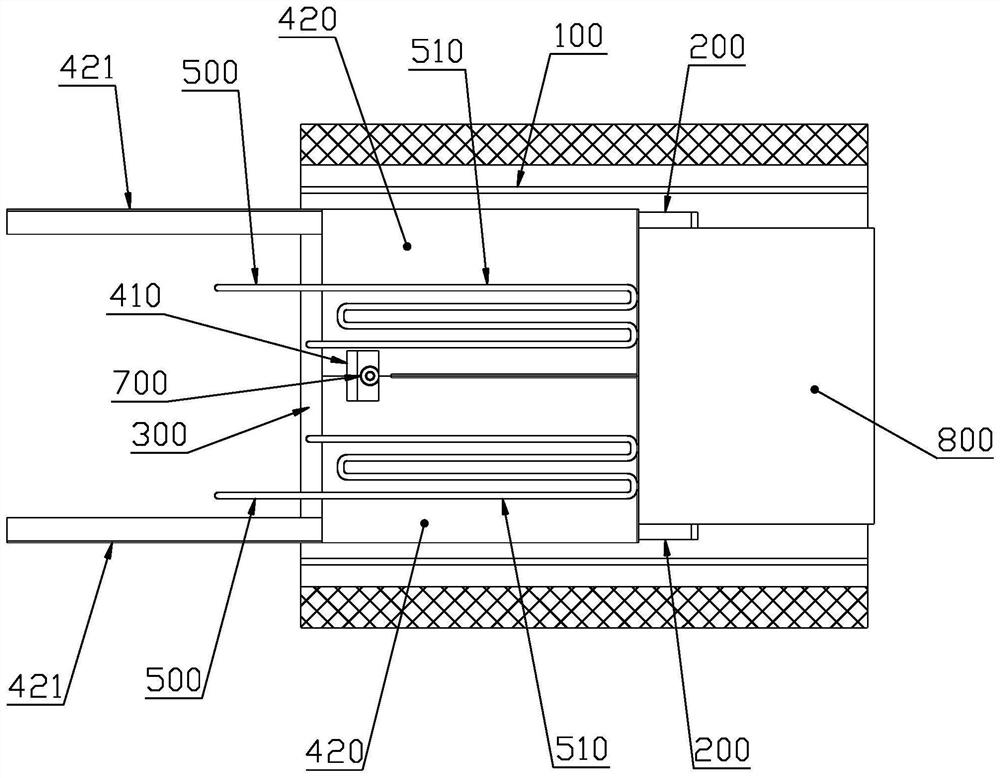

[0058] Firstly, the above-mentioned glass forming device is selected as the equipment for forming large-diameter neodymium-doped phosphate laser glass 800;

[0059] Secondly, the discharge end of the glass leaking tube 700 is penetrated into the forming cavity 600 through the leaking tube hole 410 and corresponds to the rear guide surface of the plug 300; then the annealing furnace is set on the rear side of the glass forming device , and corresponds to the rear end of the molding cavity 600;

[0060] Next, the protective gas is continuously introduced into the molding cavity 600 through the protective gas pipeline 500, and the flow rate of the introduced protective gas is controlled at 40L / h;

[0061] Next, the molten glass at 990°C in the discharge tank is sent into the molding cavity 600 through the glass leaking tube 700, the temperature of the molten glass flowing ou...

Embodiment 2

[0065] A large-diameter neodymium-doped phosphate laser glass is formed, and the process is as follows:

[0066] Firstly, the above-mentioned glass forming device is selected as the equipment for forming large-diameter neodymium-doped phosphate laser glass 800;

[0067] Secondly, the discharge end of the glass leaking tube 700 is inserted into the molding cavity 600 through the leaking tube hole 410 and corresponds to the rear guide surface of the plug 300;

[0068] Next, the protective gas is continuously introduced into the molding cavity 600 through the protective gas pipeline 500, and the flow rate of the introduced protective gas is controlled at 90L / h;

[0069] Next, the molten glass at 980°C in the discharge tank is sent into the molding cavity 600 through the glass leaking tube 700, and the temperature of the molten glass flowing out of the glass leaking tube 700 is 930°C, and the temperature on the left and right sides of the molding cavity 600 is Heating is carried ...

Embodiment 3

[0073] A large-diameter neodymium-doped phosphate laser glass is formed, and the process is as follows:

[0074] Firstly, the above-mentioned glass forming device is selected as the equipment for forming large-diameter neodymium-doped phosphate laser glass 800;

[0075] Secondly, the discharge end of the glass leakage tube 700 is penetrated into the forming cavity 600 through the leakage tube hole 410 and corresponds to the rear side guide surface of the plug 300; then the annealing furnace is arranged on the rear side of the glass forming device , and corresponds to the rear end of the molding cavity 600;

[0076] Next, the protective gas is continuously introduced into the molding cavity 600 through the protective gas pipeline 500, and the flow rate of the introduced protective gas is controlled at 60L / h;

[0077] Next, the molten glass at 990°C in the discharge tank is sent into the molding cavity 600 through the glass leaking tube 700, and the temperature of the molten gl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com