Cutting position accurate adjusting structure for coiled material film packaging

A precise adjustment, film packaging technology, applied in packaging, packaging machines, transportation and packaging, etc., can solve problems such as coil breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

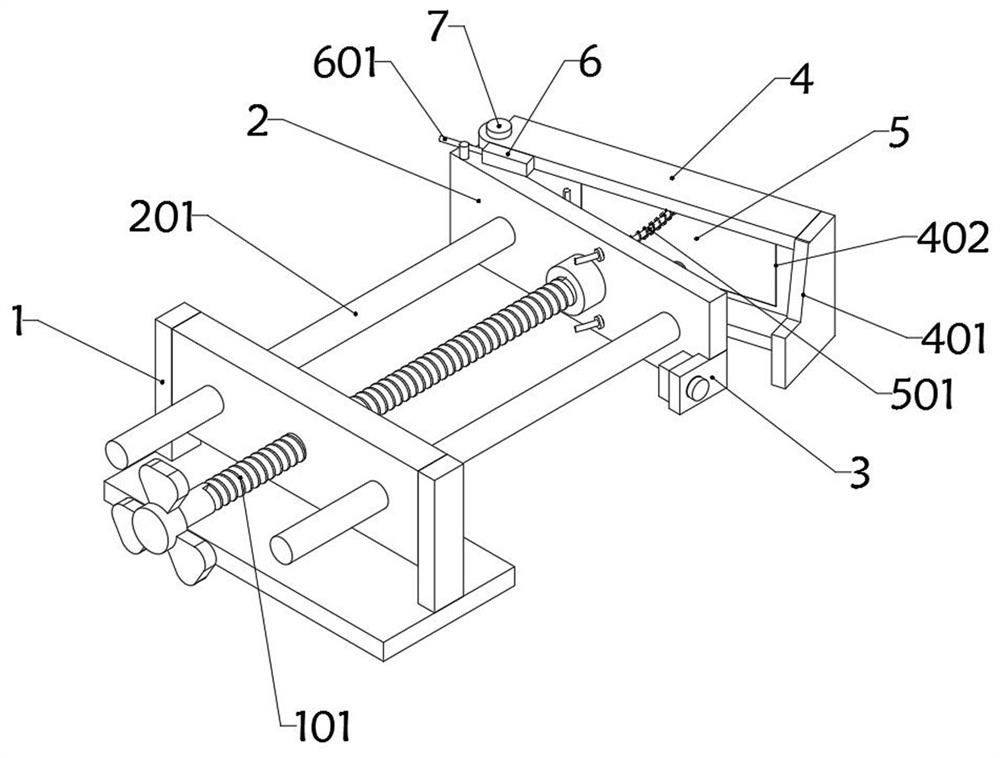

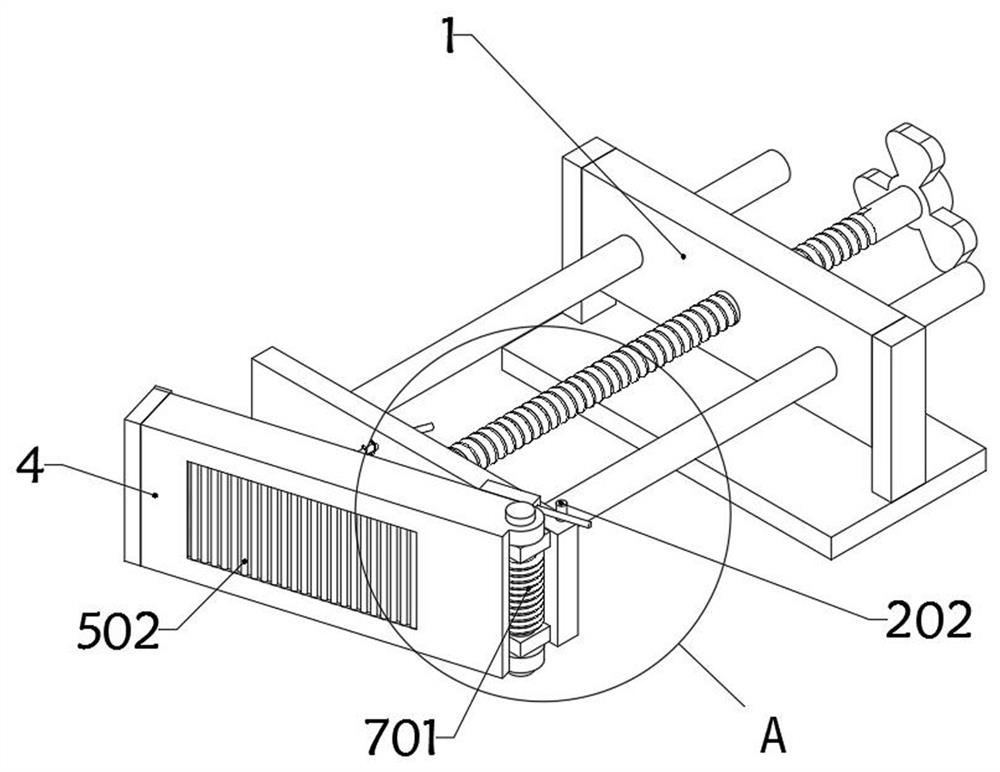

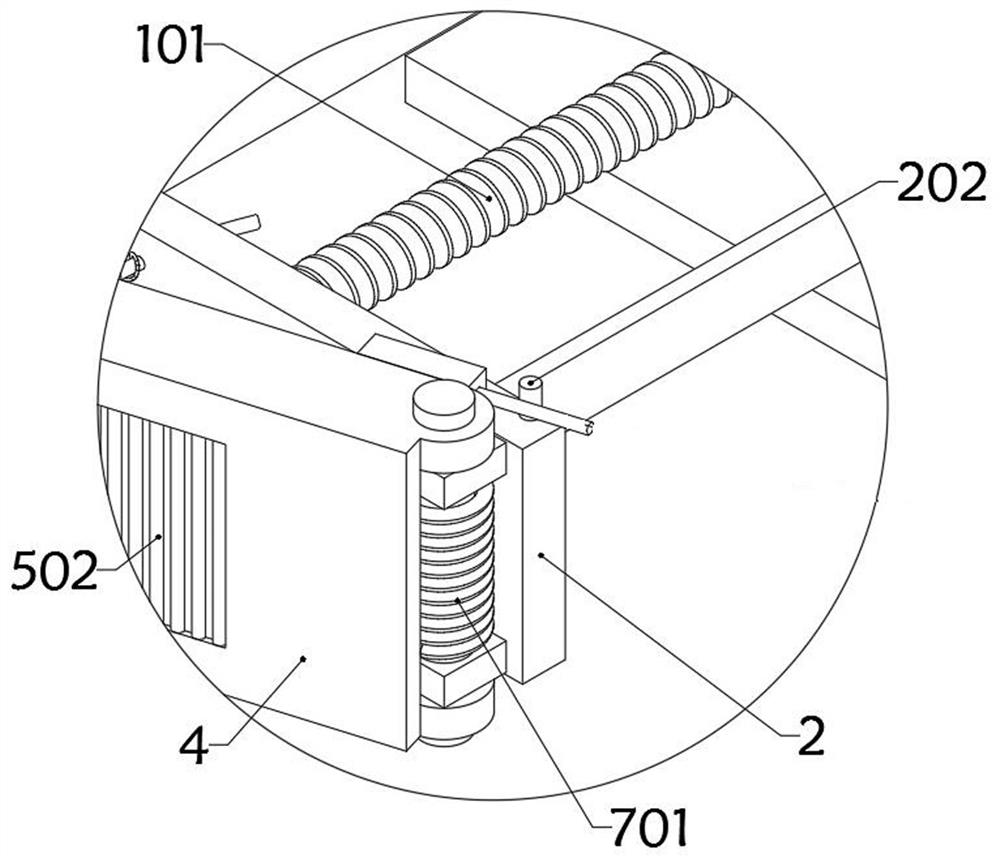

[0032] as attached figure 1 to attach Figure 8 Shown:

[0033] The invention provides a precise adjustment structure for the cutting position of coiled material film packaging, including an adjustment seat 1; a thick plate 2 is vertically installed on the adjustment seat 1; a proximity switch 3 is fixedly installed at the bottom corner of the right end of the thick plate 2; A set of rotating mechanism is installed on the left side of 2, and the rotating mechanism includes a rotating shaft 7, which is socketed with the upper and lower ends of the thick plate 2; A shaft sleeve is installed on the stainless steel baffle plate 4 at the upper and lower ends of the rotating shaft 7; the front end of the retarding plate 5 is installed on the thick plate 2 by rotating the rotating shaft 7 as the center of rotation; Limiting blocks 6 are respectively fixedly installed at the corners.

[0034] Wherein, the middle part of the adjustment seat 1 is screwed with an adjusting bolt 101 fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com