Precise small part smoothing device

A precise and smooth technology, used in surface polishing machine tools, grinding/polishing equipment, machine tools suitable for grinding workpiece edges, etc., can solve problems such as low efficiency and large footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

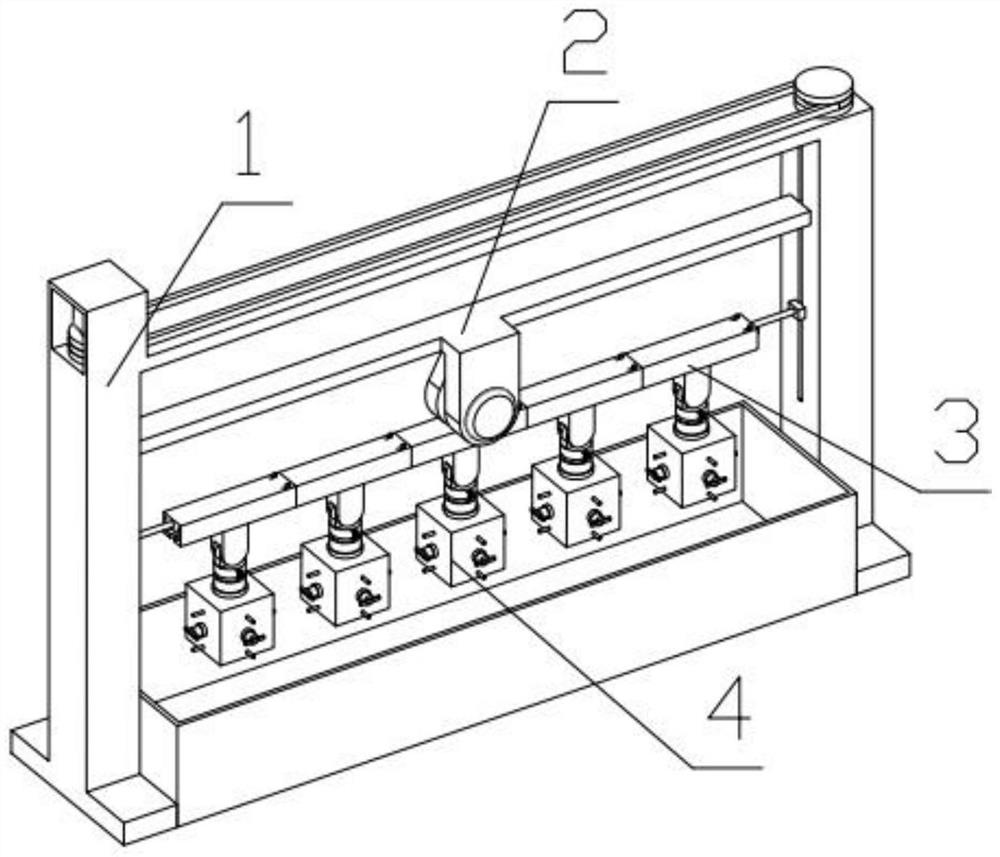

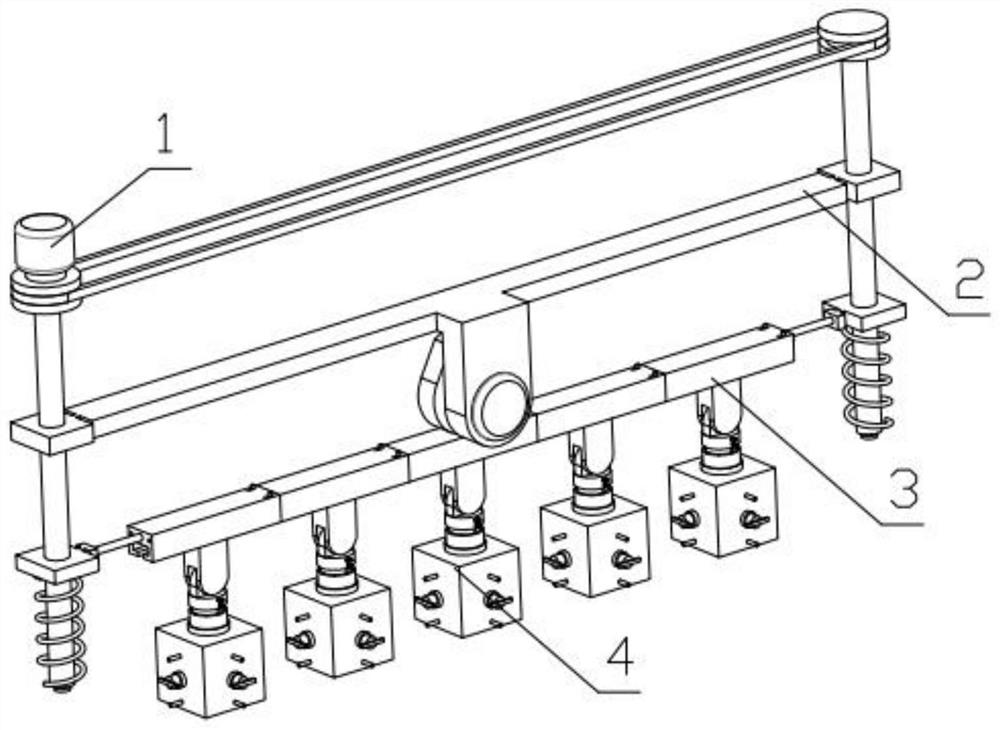

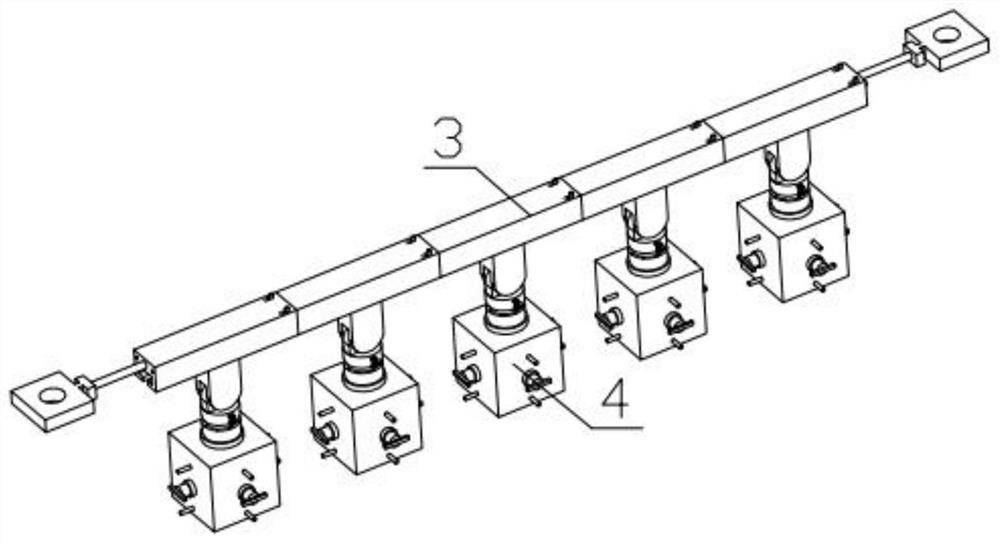

[0033] Combine below Figure 1-15 Describe this embodiment, a precise light sliding device for small pieces, including a device lifting mechanism 1, an up and down streamer mechanism 2, a combined connection mechanism 3 and a precise streamer mechanism 4, the upper and lower streamer mechanisms 2 are slidably installed on the device lifting mechanism 1 In the groove of the device, the device lifting mechanism 1 is threadedly connected with the upper and lower streamer mechanisms 2, the combined connecting mechanism 3 is fixedly installed on the device lifting mechanism 1, and the combined connecting mechanism 3 and the precise streamer mechanism 4 are hinged.

specific Embodiment approach 2

[0035] Combine below Figure 1-15Describe this embodiment, this embodiment will further explain the second embodiment, the device lifting mechanism 1 includes a bottom box 1-1, a U-shaped frame 1-2, a lifting motor 1-3, a sprocket 1-4, a chain 1-5, lifting threaded rod 1-6, supporting spring 1-7, the bottom box 1-1 is fixedly installed on the U-shaped frame 1-2, the lifting motor 1-3 is fixedly installed on the U-shaped frame 1-2, and the lifting The output end of the motor 1-3 is fixedly equipped with a sprocket 1-4, the sprocket 1-4 is meshed with the chain 1-5, the sprocket 1-4 is fixedly connected with the lifting threaded rod 1-6, and the lifting threaded rod 1-6 The rotation is installed in the groove provided on the U-shaped frame 1-2, and the support spring 1-7 is fixedly installed on the U-shaped frame 1-2.

specific Embodiment approach 3

[0037] Combine below Figure 1-15 Describe this embodiment, this embodiment will further explain the first embodiment, the upper and lower streamer mechanism 2 includes a lifting beam plate 2-1, a toggle motor 2-2, a cam 2-3, and the lifting beam plate 2-1 is fixed A toggle motor 2-2 is installed, and the output end of the toggle motor 2-2 is fixedly equipped with a cam 2-3, and the lift beam plate 2-1 is slidably installed in the groove provided on the U-shaped frame 1-2, and the lift beam Plate 2-1 is threadedly connected with lifting threaded rod 1-6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com