Diode chip and manufacturing method thereof

A manufacturing method and diode technology, applied in the field of diodes, can solve problems such as poor heat dissipation capability, and achieve the effects of short reverse recovery time, improved heat dissipation capability, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

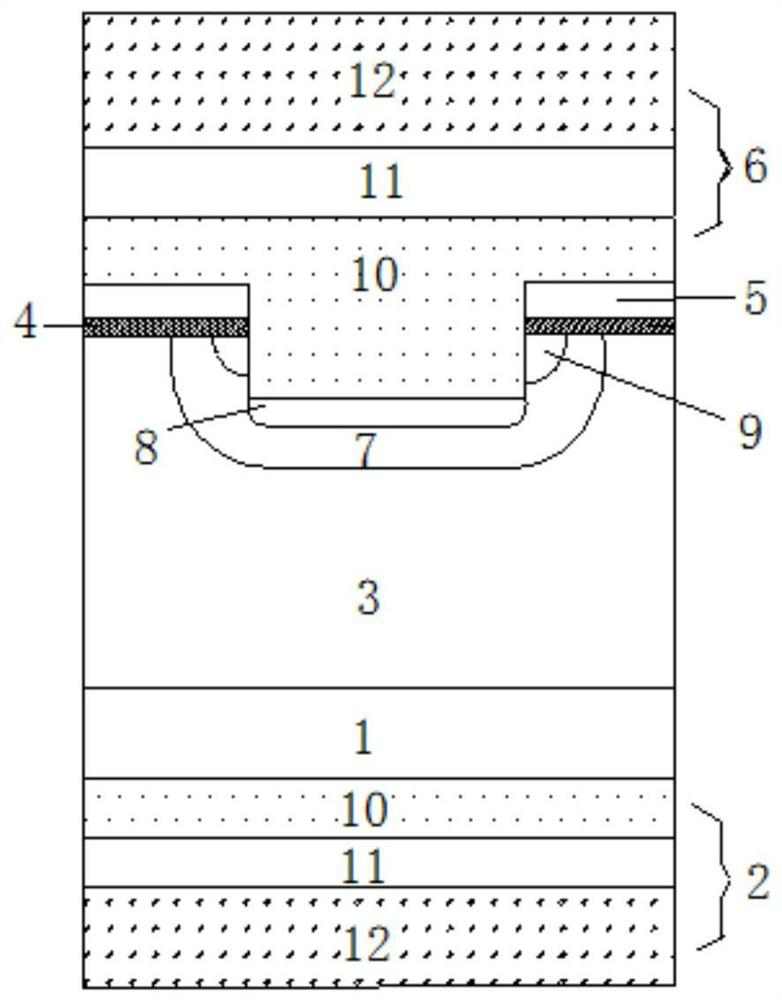

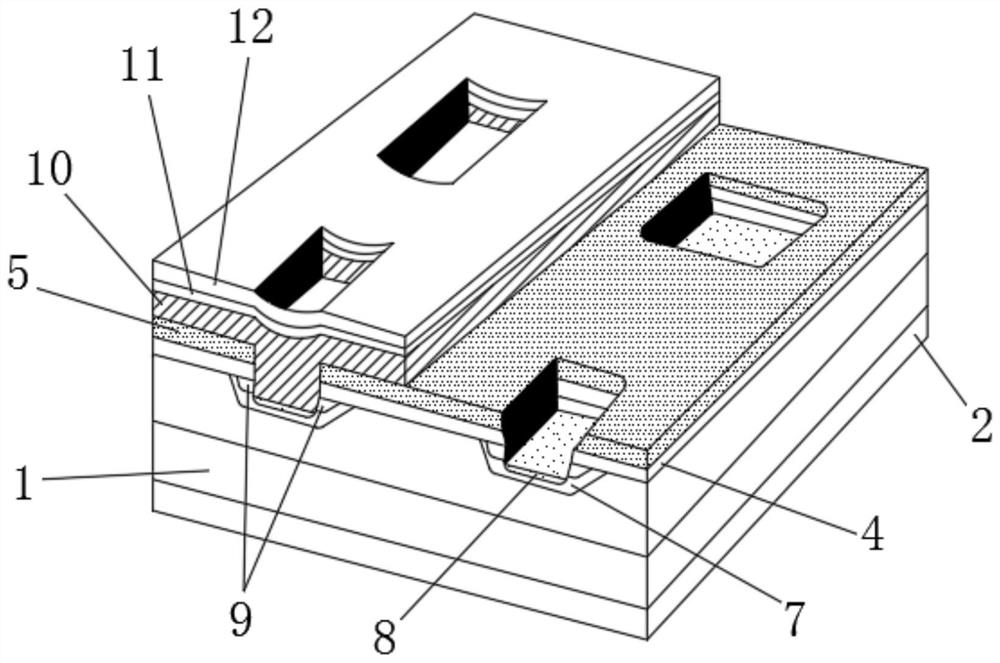

[0040] like Figure 1~2 Shown is the structural representation of cellular structure and diode chip of the present invention:

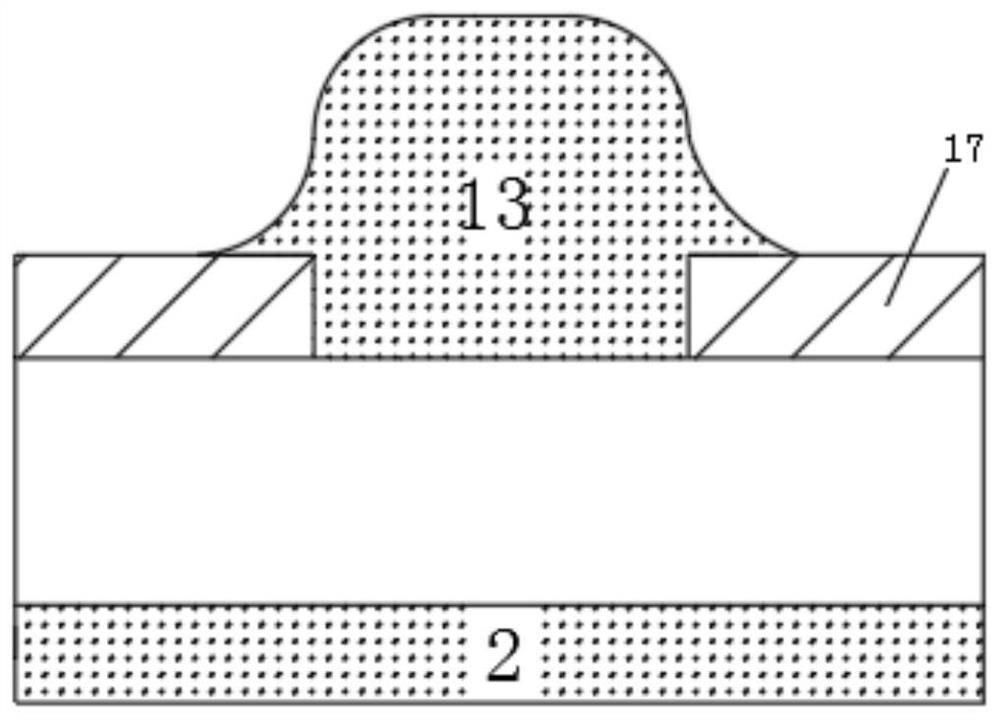

[0041] The invention provides a diode chip, which includes a plurality of cells connected in parallel with each other, the cells include an N+ substrate 1, a back metal layer 2 is provided on the back side of the N+ substrate 1, and a N+ substrate 1 is provided on the front side. - epitaxial region 3, the front of N-epitaxial region 3 is provided with gate oxide layer 4, polysilicon 5, metallization layer 6 in sequence; the front middle part of said N-epitaxial region 3 is embedded with P-type base region 7, metallization layer 6 There is a raised part on the back, and the raised part is embedded in the P-type base area 7, and the N+ area 9 is arranged around the raised part, and the P+ area 8 is arranged...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com