Test key structure and wafer stacking structure

A stacking structure and test key technology, which is applied in semiconductor/solid-state device testing/measurement, electrical components, electric solid-state devices, etc., can solve the problems of inability to distinguish the order of test pads and ambiguity of related marks, so as to prevent human operation errors , reduced manpower, and the effect of saving test time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

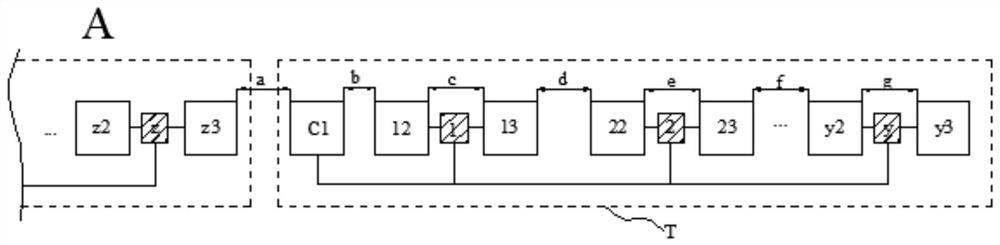

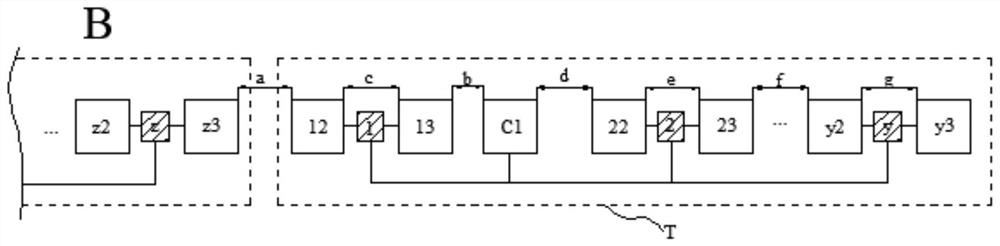

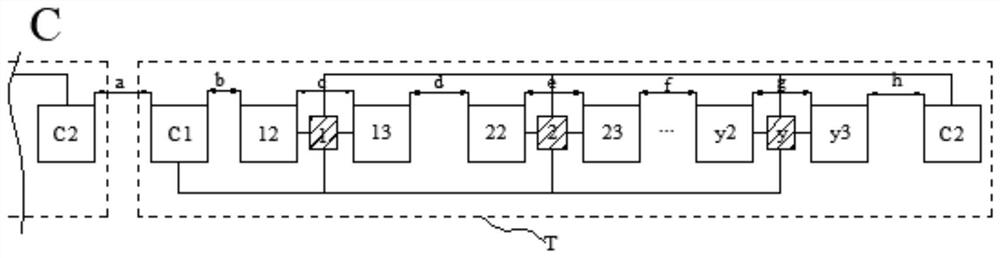

[0041] Based on the above research, an embodiment of the present invention provides a test key structure. The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. The advantages and features of the present invention will become clearer from the following description. It should be noted that the drawings are all in a very simplified form and use imprecise scales, and are only used to facilitate and clearly assist the purpose of illustrating the embodiments of the present invention.

[0042] The embodiment of the present invention provides a test key structure, including:

[0043] At least one test key unit, the test key unit is distributed with several test elements to be tested and a plurality of test pads distributed at intervals, the distance between adjacent test pads is not completely the same, multiple test pads in the test key unit The test pad is asymmetric about the central axis of the tes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com