Method for predicting corrosion rate of submarine crude oil pipeline based on PCA-ABC-SVM model

A PCA-ABC-SVM, corrosion rate technology, applied in computational models, biological models, instruments, etc., can solve the problems of large amount of basic data requirements and insufficient prediction reliability, so as to improve prediction accuracy and reduce data. Volume requirements, the effect of reducing the amount of data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

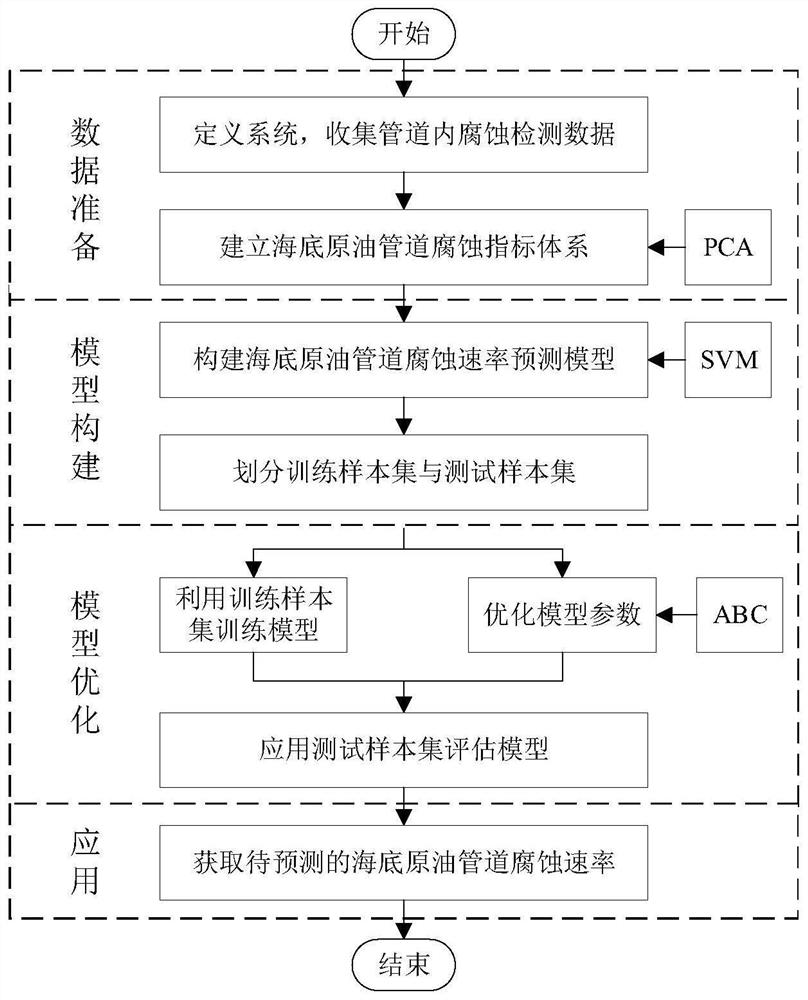

[0025] The present invention will be further described below in conjunction with accompanying drawing:

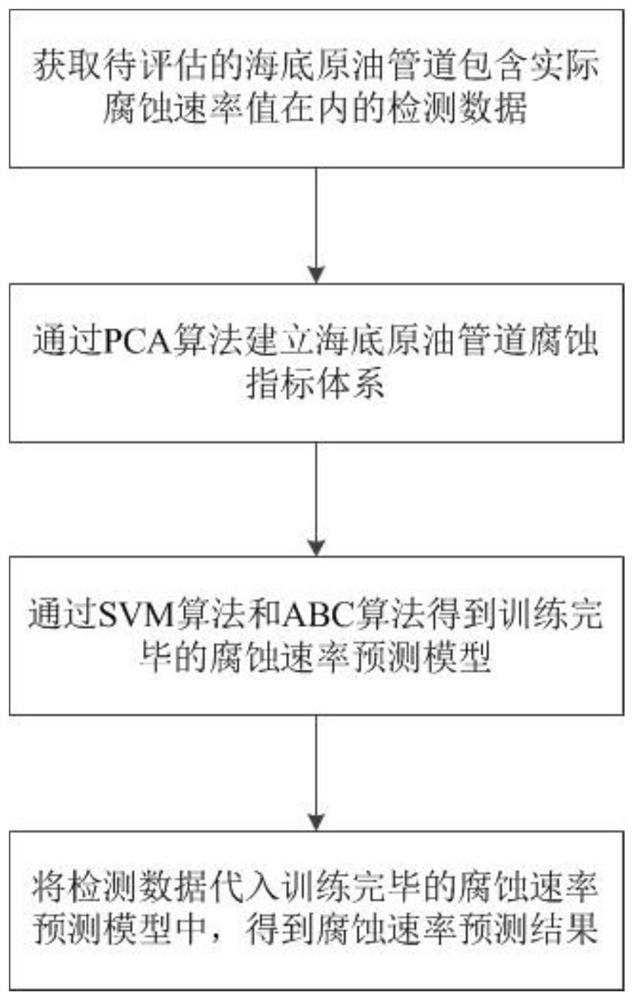

[0026] Such as figure 1 As shown, it is a structural schematic diagram of the method for predicting the corrosion rate of submarine crude oil pipelines based on the PCA-ABC-SVM model provided by this scheme.

[0027] The method for predicting corrosion rate of submarine crude oil pipeline based on PCA-ABC-SVM model of the present invention comprises the steps:

[0028] S1. Obtain the detection data including the actual corrosion rate value of the submarine crude oil pipeline to be evaluated.

[0029] Further, the detection data include at least water content, carbon dioxide content, hydrogen sulfide content, chloride ion content, calcium and magnesium ion content, dissolved oxygen content, pH value, temperature, pressure, flow rate and actual corrosion rate value in the pipeline.

[0030] In some embodiments of this solution, there are at least 100 sets of detection data....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com