Industrial part size measurement method based on 3D visual sensor

A technology of visual sensor and measurement method, which is applied in the direction of measuring devices, instruments, image analysis, etc., can solve undiscovered problems, achieve the effect of improving production efficiency and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

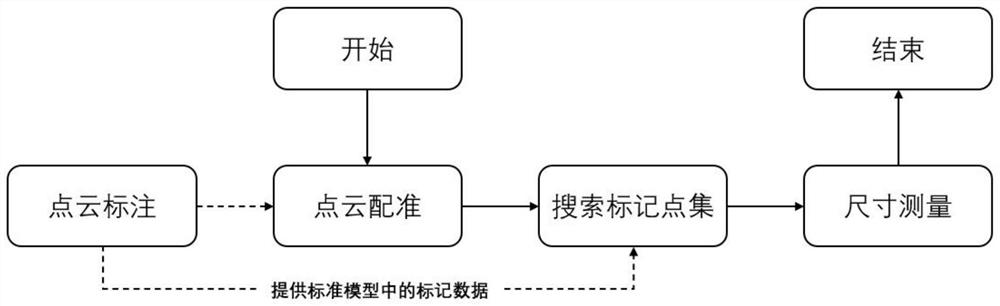

[0069] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

[0070] A method for measuring the size of industrial parts based on a 3D vision sensor, comprising the following steps:

[0071] Step 1. Carry out manual labeling based on the standard model, select the point set to be detected for the standard model, and mark the basic geometric shapes that constitute the point set, including points, lines, surfaces, circles and cylinders;

[0072] The specific method of said step 1 is: based on OpenSceneGraph (OSG) to realize the three-dimensional interactive visualization system to complete the rendering, visualization and basic interactive operation of the point set in the standard model, including selecting or selecting a plurality of target points on the standard model Deselect, and label the geometric shapes that make up this set of points once the selection is done;

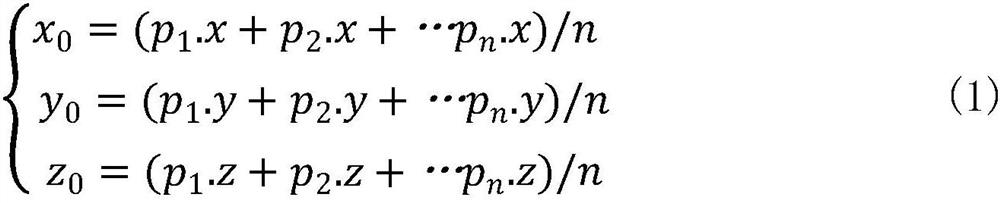

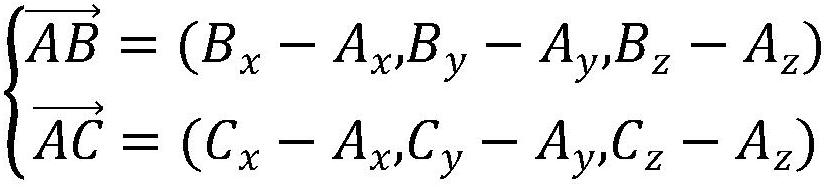

[0073] The concrete steps of described...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com