Wastewater zero discharge system based on efficient concentrating and spray drying integrated treatment

A zero-discharge, waste water technology, which is applied in the direction of special treatment targets, water/sewage treatment, heating water/sewage treatment, etc., can solve the problems of high operating costs, lengthy and complicated process, and large steam consumption, so as to reduce water consumption , Realize the effect of low temperature evaporation and stable atomization particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

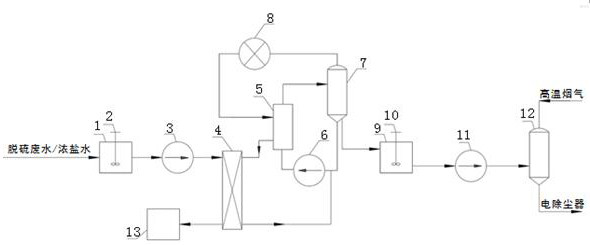

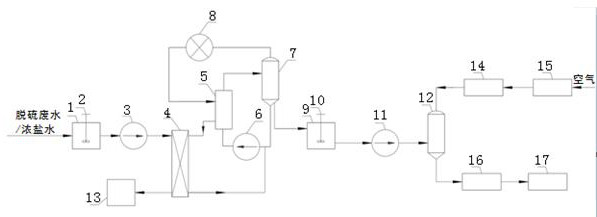

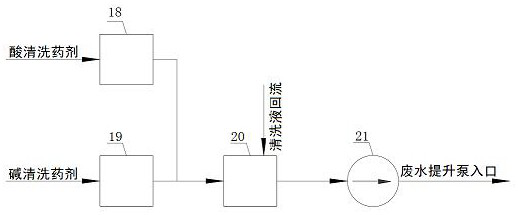

[0058] Embodiment: Taking the treatment of desulfurization wastewater as an example, a waste water zero discharge system based on high-efficiency concentration and spray drying integrated treatment includes the following steps: collecting the desulfurization waste water swirled out of the waste water cyclone station into the waste water collection tank, stirring the waste water The desulfurization wastewater is continuously stirred to prevent the precipitation of desulfurization wastewater particles. The wastewater collection tank is equipped with a remote ultrasonic liquid level transmitter, which is linked with the wastewater lifting pump for liquid level. The wastewater lifting pump transports the desulfurization wastewater raw liquid to the preheater. The desulfurization wastewater is preheated. After preheating, the desulfurization wastewater flows to the inlet of the forced circulation pump, and the pressure of the forced circulation pump drives the feed liquid into the he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com