Rollover device for composite material manufacturing and using method thereof

A composite material and mold turning technology, which is applied in the field of mold turning devices, can solve the problems of being unable to apply to a clean environment of composite materials, failing to meet the requirements of industrial production, and affecting the efficiency and quality of laying layers, so as to ensure the quality of laying and shorten The effect of production cycle and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical scheme of the present invention will be clearly and completely described below in conjunction with the embodiments and the accompanying drawings. Obviously, the described embodiments are only preferred embodiments of the present invention, not all embodiments, nor are they intended to be a reference to the present invention. For other forms of limitations, any skilled person who is familiar with this field may use the disclosed technical content to make changes or remodel equivalent changes. However, any simple modifications, equivalent changes and modifications made to the above embodiments according to the technical essence of the present invention without departing from the content of the technical solution of the present invention still belong to the protection scope of the technical solution of the present invention.

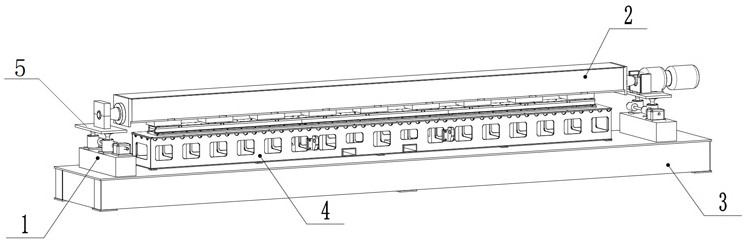

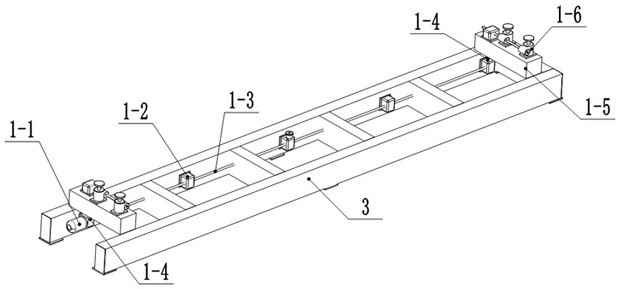

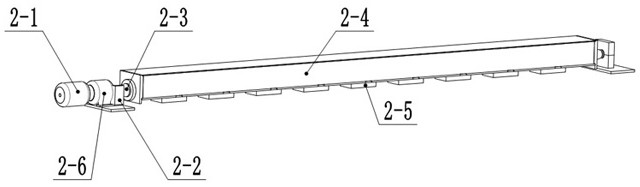

[0028] This embodiment is a kind of overmolding device for composite material manufacturing, such as figure 1 As shown, it includes a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com