Sorting device and sorting method

A sorting device and decentralized technology, applied in sorting and other directions, can solve problems such as poor versatility, limited plant capacity, and difficulty in meeting sorting types, and achieve the effect of saving production land and improving production utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

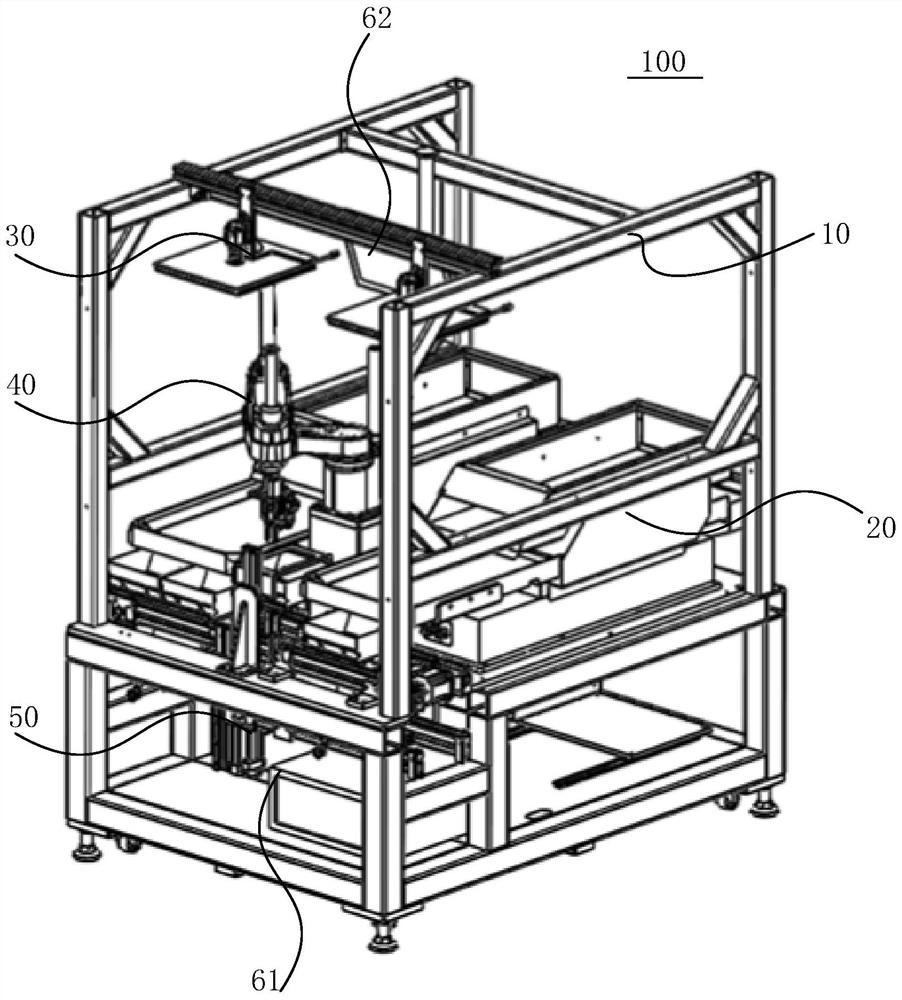

[0040] see Figure 1 to Figure 6 , an embodiment of the present application provides a sorting device 100 . The sorting device 100 is used for sorting materials and outputting the sorted materials. The sorting device 100 can sort a variety of different materials at the same time, so it can reduce the usage of sorting equipment, improve production utilization, reduce equipment cost and save equipment occupied space.

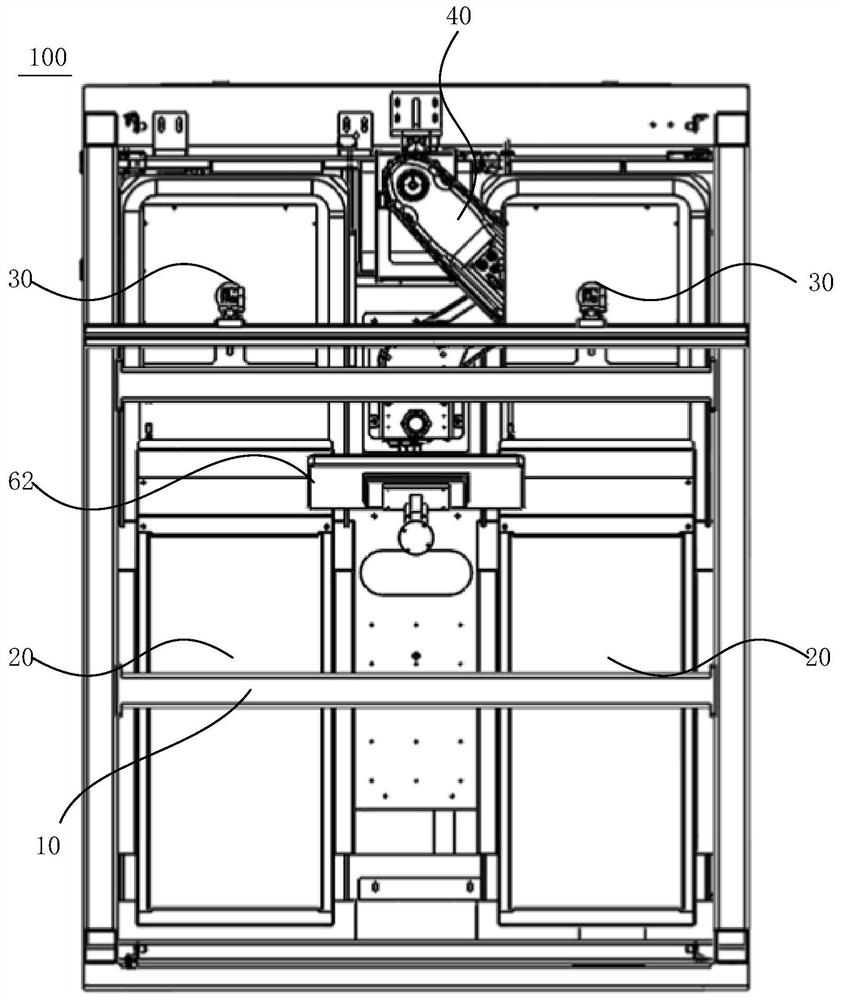

[0041] The sorting device 100 includes a frame 10 , a feeding mechanism 20 , an identification mechanism 30 , a picking mechanism 40 , an output mechanism 50 and a control mechanism 60 . The feeding mechanism 20 , the identification mechanism 30 , the pick-up mechanism 40 , the output mechanism 50 and the control mechanism 60 are respectively arranged on the frame 10 . The control mechanism 60 is electrically connected to the feeding mechanism 20 , the identifying mechanism 30 , the picking mechanism 40 and the output mechanism 50 , and controls the above mechan...

Embodiment 2

[0045] see Figure 1 to Figure 8 , a sorting device 100 provided in this embodiment can be applied to sort materials. This embodiment is an improvement made on the technical basis of the above-mentioned embodiment 1. Compared with the above-mentioned embodiment 1, the difference lies in:

[0046] The feeding mechanism 20 includes a feeding platform 21 and a dispersing element 22 . The feeding platform 21 is arranged on the dispersing element 22 . The dispersing element 22 is arranged on the frame 10 . The feeding table 21 is used for placing materials to be sorted. Distributor 22 is connected to control mechanism 60 . The dispersing member 22 receives the feed control signal of the control mechanism 60 to drive the feed table 21 to vibrate, so that the materials placed on the feed table 21 are vibrated and dispersed, so that the identification mechanism 30 can accurately identify each material respectively, and The pick-up mechanism 40 performs precise pick-up.

[0047] ...

Embodiment 3

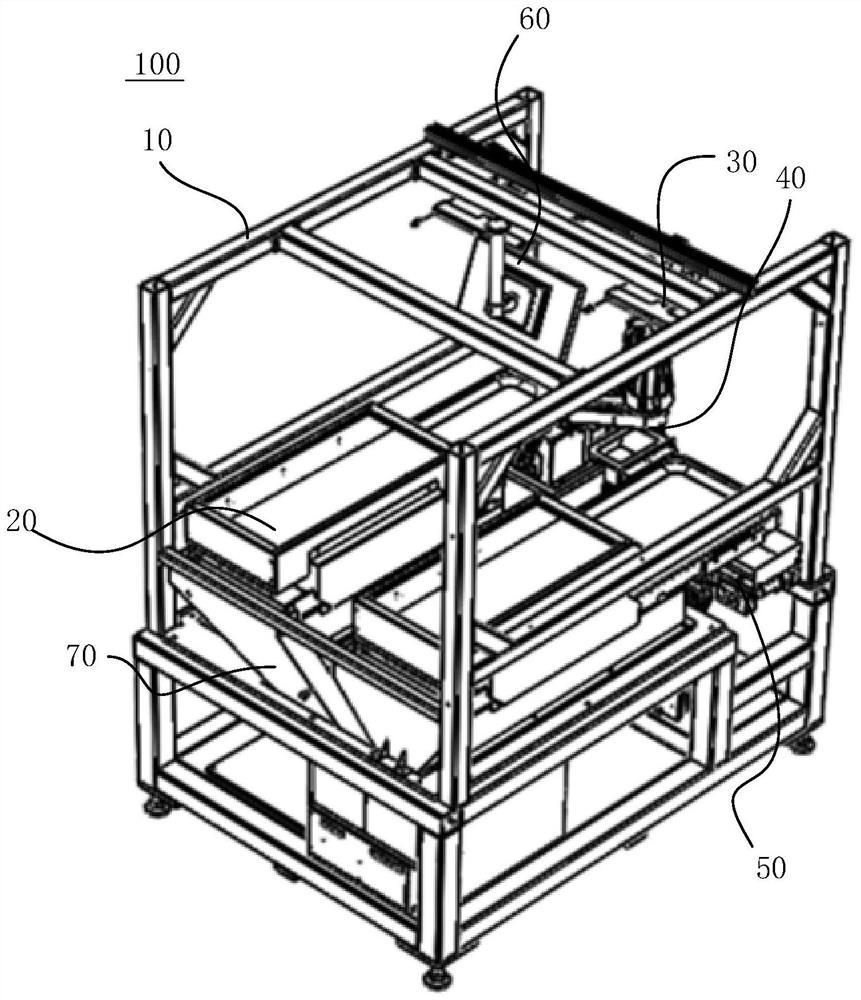

[0052] see Figure 1 to Figure 8 , a sorting device 100 provided in this embodiment can be applied to sort materials. This embodiment is an improvement made on the technical basis of the above-mentioned embodiment 1 and embodiment 2. Compared with the above-mentioned embodiment 1, the difference lies in:

[0053] In this embodiment, the sorting device 100 further includes a recovery mechanism 70 . The recovery mechanism 70 is connected with the feeding mechanism 20 . The recovery mechanism 70 is used to recover the remaining materials after the operation is completed.

[0054] Specifically, the recovery mechanism 70 includes a recovery pipeline 71 and a recovery box 72 . One end of the recovery pipeline 71 communicates with the side of the picking platform 212 away from the pick-up mechanism 40 , and the other end of the recovery pipeline 71 communicates with the recovery box 72 . The recycling box 72 is arranged under the feeding mechanism 20, and the recycling box 72 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com