Antibiotic-free compound feed for broilers

A technology of compound feed without antibiotics, applied in animal feed, animal feed, additional food elements, etc., can solve the problems of bacterial resistance, human and ecological environment hazards, antibiotic residues, etc., and achieve good disease resistance, intestinal tract Healthy, little odor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

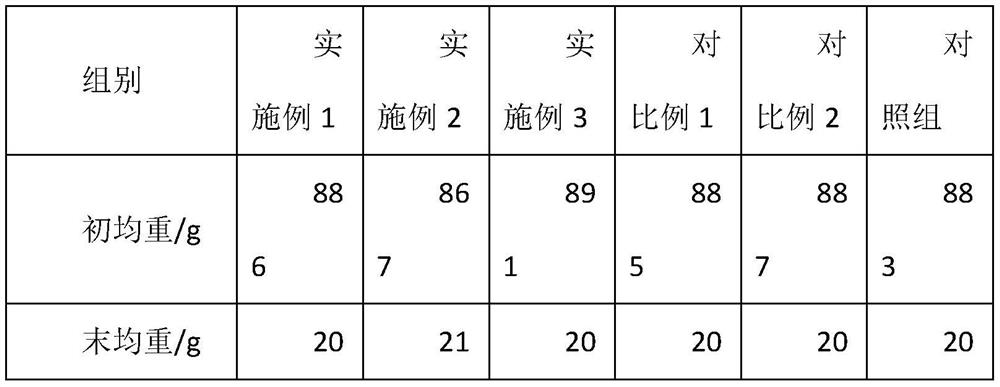

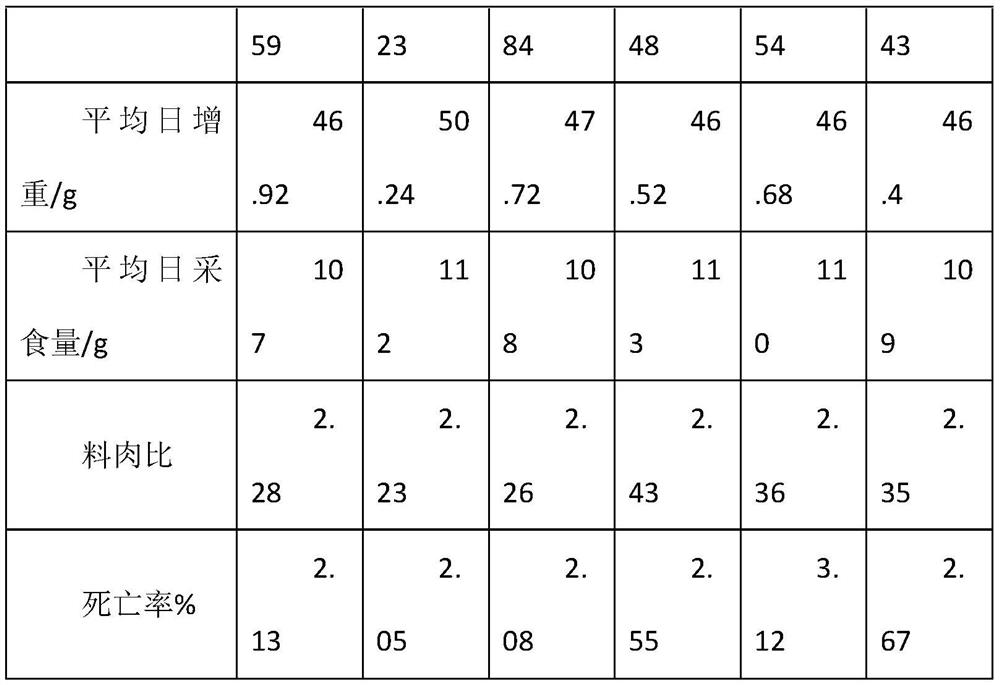

Examples

Embodiment 1

[0026] A compound feed for broilers without antibiotics, consisting of the following raw material components in parts by weight: 64.7 parts of corn, 12.5 parts of 46 soybean meal, 1.5 parts of soybean oil, 2.8 parts of lard, 3 parts of corn gluten powder, 4 parts of subflour, puffed soybean powder 3 parts, 3 parts of cottonseed meal, 1.5 parts of fly maggot protein feed, 1.1 parts of stone powder, 0.9 parts of calcium hydrogen phosphate, 2 parts of core premix. Core premix components: 0.58 parts of 70 lysine, 0.23 parts of 99 methionine, 0.15 parts of 98 threonine, 0.03 parts of 98 tryptophan, 0.2 parts of feed grade sodium chloride, 0.08 parts of choline, vitamin premix 0.03 part, 0.1 part of trace element premix, 0.02 part of compound enzyme preparation, 0.04 part of sodium butyrate, 0.03 part of tannic acid, 0.5 part of zeolite powder. Prepared according to existing conventional technical methods.

[0027] The trace element premix contains Cu, Fe, Zn, Mn, Co, I, Se trace e...

Embodiment 2

[0030] A compound feed for broilers without antibiotics, consisting of the following ingredients by weight: 56.3 parts of corn, 12 parts of soybean meal 46, 1.3 parts of soybean oil, 2.4 parts of lard, 10 parts of broken rice, 3 parts of corn gluten powder, and 3 parts of secondary meal 3 parts of expanded soybean powder, 3 parts of cottonseed meal, 2 parts of fly maggot protein feed, 1.1 parts of stone powder, 0.9 parts of calcium hydrogen phosphate, and 2 parts of core premix. Core premix components: 0.58 parts of 70 lysine, 0.23 parts of 99 methionine, 0.15 parts of 98 threonine, 0.03 parts of 98 tryptophan, 0.2 parts of feed grade sodium chloride, 0.08 parts of choline, vitamin premix 0.03 part, 0.1 part of trace element premix, 0.02 part of compound enzyme preparation, 0.05 part of sodium butyrate, 0.02 part of tannic acid, 0.5 part of zeolite powder. Prepared according to existing conventional technical methods.

[0031] The trace element premix contains Cu, Fe, Zn, Mn,...

Embodiment 3

[0034] A compound feed for broilers without antibiotics, which consists of the following raw materials in parts by weight: 65 parts of corn, 12.5 parts of 46 soybean meal, 1.6 parts of soybean oil, 2.4 parts of lard, 4 parts of corn gluten powder, 4 parts of subflour, puffed soybean powder 3 parts, 2 parts of cottonseed meal, 1.5 parts of fly maggot protein feed, 1.1 parts of stone powder, 0.9 parts of calcium hydrogen phosphate, 2 parts of core premix. Core premix components: 0.62 parts of 70 lysine, 0.22 parts of 99 methionine, 0.14 parts of 98 threonine, 0.03 parts of 98 tryptophan, 0.2 parts of feed grade sodium chloride, 0.08 parts of choline, vitamin premix 0.03 part, 0.1 part of trace element premix, 0.02 part of compound enzyme preparation, 0.05 part of sodium butyrate, 0.02 part of tannic acid, 0.5 part of zeolite powder. Prepared according to existing conventional technical methods.

[0035] The trace element premix contains Cu, Fe, Zn, Mn, Co, I, Se trace elements....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com