Ternary precursor with radial spherical top cone structure, positive electrode material and preparation method

A positive electrode material and radial technology, which is applied in the field of ternary precursors and positive electrode materials and preparations with radial spherical top cone structures, can solve the problems of uneven distribution of material particles, unstrict control of influencing factors, and low possibility of experiment repetition. , to achieve the effects of low raw material cost, stable Coulombic efficiency, and good cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

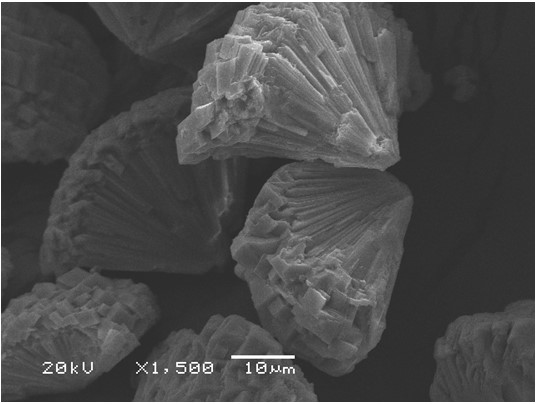

[0059] The cone portion of the ternary precursor of the radial-like spherical-top pyramid structure is a long strip of primary particles that grow radially, and the top of the sphere is an orderly stacked block-shaped primary particle that forms a secondary agglomerate; the radial The chemical formula of the ternary precursor of the spherical top-cone structure is Ni 1 / 3 Co 1 / 3 Mn 1 / 3 (OH) 2 ; the average length of the elongated primary particles is 10 μm; the average particle size of the surface layer bulk primary particles is 2 μm, and the average thickness of the stacking is 3 μm.

[0060] like figure 1 As shown in the embodiment of the present invention, the ternary precursor Ni of the radial-like spherical top pyramid structure 1 / 3 Co 1 / 3 Mn 1 / 3 (OH) 2 The cone part is radially growing elongated primary particles, and the top of the sphere is an orderly accumulation of massive primary particles, which form secondary agglomerates with regular morphology and uniform ...

Embodiment 2

[0073] The cone portion of the ternary precursor of the radial-like spherical-top pyramid structure is a long strip of primary particles that grow radially, and the top of the sphere is an orderly stacked block-shaped primary particle that forms a secondary agglomerate; the radial The chemical formula of the ternary precursor of the spherical top-cone structure is Ni 0.5 Co 0.2 Mn 0.3 (OH) 2 ; the average length of the elongated primary particles is 12 μm; the average particle size of the bulk primary particles of the surface layer is 3 μm, and the average stacking thickness is 4 μm.

[0074] like Figure 4 As shown in the embodiment of the present invention, the ternary precursor Ni of the radial-like spherical top pyramid structure 0.5 Co 0.2 Mn 0.3 (OH) 2 The cone part is radially growing elongated primary particles, and the top of the sphere is an orderly accumulation of massive primary particles, which form secondary agglomerates with regular morphology and uniform...

Embodiment 3

[0087] The cone portion of the ternary precursor of the radial-like spherical-top pyramid structure is a long strip of primary particles that grow radially, and the top of the sphere is an orderly stacked block-shaped primary particle that forms a secondary agglomerate; the radial The chemical formula of the ternary precursor of the spherical top-cone structure is Ni 0.8 Co 0.1 Mn 0.1 (OH) 2 ; the average length of the elongated primary particles is 8 μm; the average particle diameter of the surface layer block-shaped primary particles is 1 μm, and the average stacking thickness is 3 μm.

[0088] After testing, the ternary precursor Ni of the radial spherical top pyramid structure in the embodiment of the present invention is 0.8 Co 0.1 Mn 0.1 (OH) 2 The cone part is radially growing elongated primary particles, and the top of the sphere is an orderly accumulation of massive primary particles, which form secondary agglomerates with regular morphology and uniform distribu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com