A landing light drive mechanism

A technology of driving mechanism and landing light, applied in the direction of transmission box, transmission device, mechanical equipment, etc., can solve the problems of increasing the air resistance of the aircraft, large overall structure size, large gear gap, etc., and achieves compact structure, not easy to wear, and weight. light effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

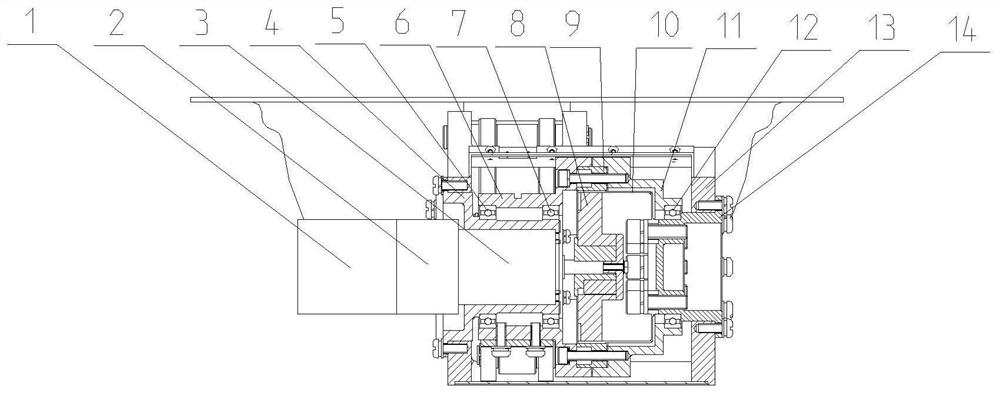

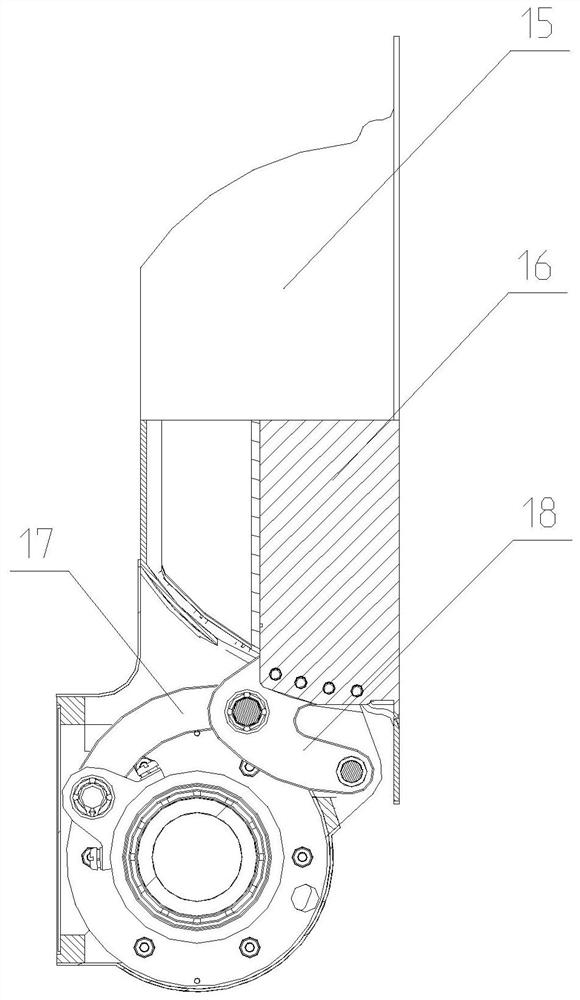

[0023] see figure 1 , The driving mechanism of the landing light in this embodiment includes a motor 1, a brake 2, a planetary reducer 3, a front fixed end cover 4, a bearing 5, a front transmission hollow shaft 6, a bearing 7, a harmonic reducer wave generator 8, a harmonic wave Reducer wave steel wheel 9, harmonic reducer flexible wheel 10, rear drive hollow shaft 11, bearing 12, structural frame 13, rear fixed end cover 14, lampshade 15, lamp holder 16, connecting rod 17, connecting corner block 18

[0024] The end cover 4 is fixed before being installed on the structural frame 13, and the end cover 14 is fixed after being installed on the structural frame 13;

[0025] The planetary reducer 3 installed on the front fixed end cover 4 , the brake 2 fixed with the planetary reducer 3 , and the motor 1 fixed with the brake 2 .

[0026] The output shaft of the planetary reducer 3 is fixedly connected with the harmonic reducer wave generator 8; the harmonic reducer steel wheel 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com