High-power thin coal seam coal mining machine rocker arm with front-mounted planetary reducer

A planetary reducer and planetary deceleration technology, applied in slitting machinery, cutting machinery, driving devices, etc., can solve the problems of small mining height, small blade height, poor coal charging effect, etc., and achieve improved coal charging. Effect, reduction mechanism simplification, effect of avoiding coal accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

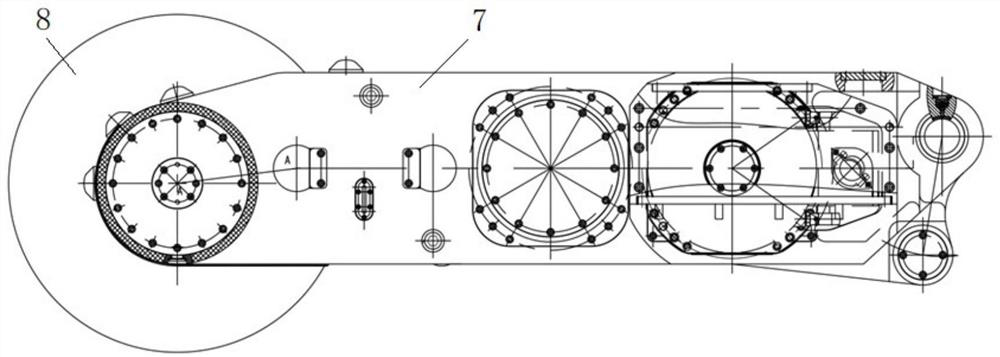

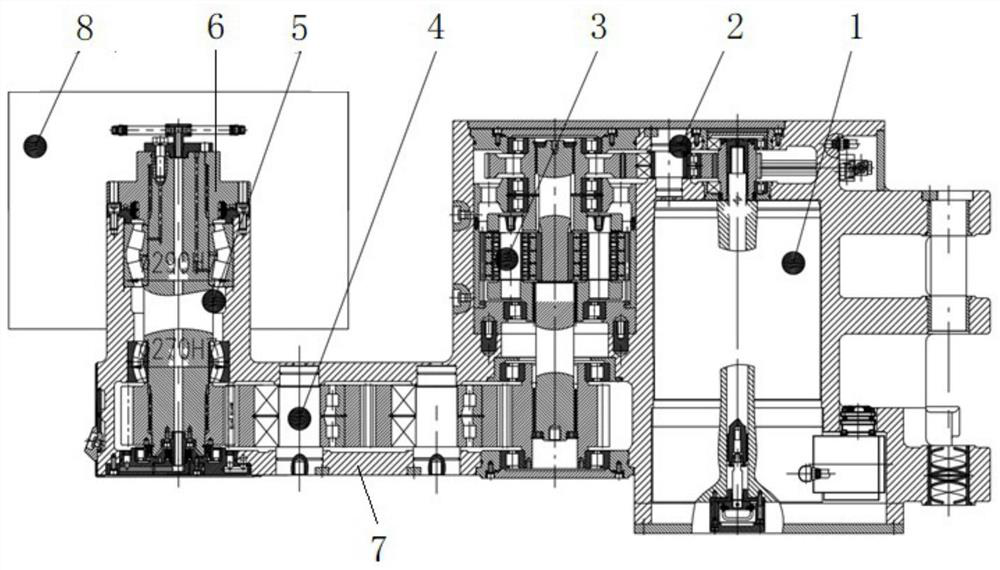

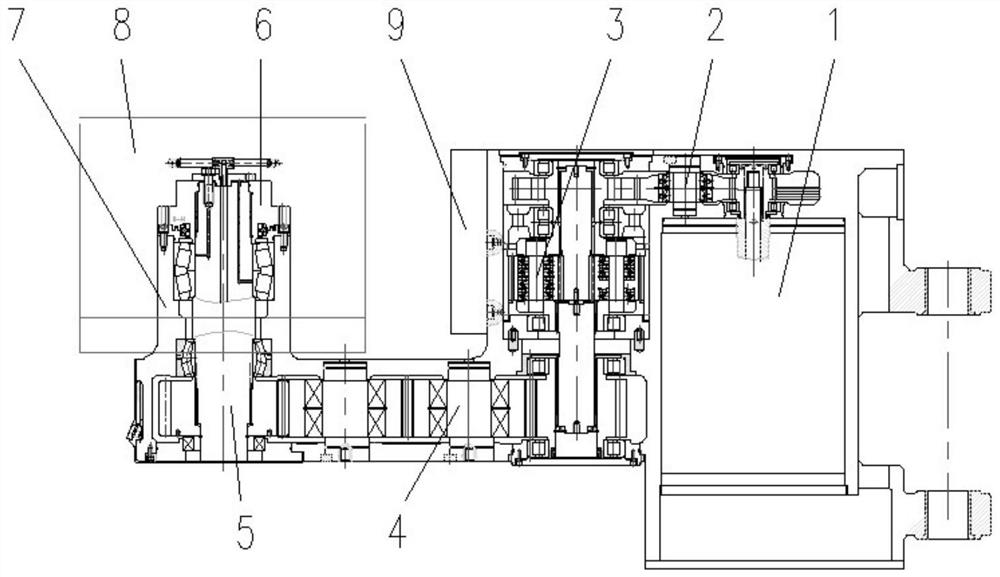

[0029] The invention discloses a rocker arm of a front-mounted high-power thin coal seam shearer with a planetary reducer, such as Figure 1-5 As shown, it includes the rocker arm housing 7 and the cutting motor 1 installed in the rocker arm housing and sequentially connected by transmission, the first-stage spur gear transmission system 2, the planetary reduction mechanism 3, the second-stage spur gear transmission system 4 and the long output shaft 5. The high-speed end installation part and the low-speed end installation part of the rocker arm housing extend forward and backward, and are opposite to each other at intervals left and right, so that the rocker arm housing as a whole is U-shaped. The rocker arm of the U-shaped structure is suspended from the coal wall side of the shearer body as a whole, which can avoid the impact of the rocker arm lifting on the coal shearer space. The axes of the cutting motor and the planetary reduction mechanism both extend forward and bac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com