Down-the-hole drill for hydraulic engineering construction

A technology for hydraulic engineering and down-the-hole drilling, which is applied to drill pipes, drill pipes, drilling equipment, etc., can solve the problem of high drilling costs, and achieve the effects of reducing costs, facilitating disassembly, and increasing the height of rise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The following is attached Figure 1-8 The application is described in further detail.

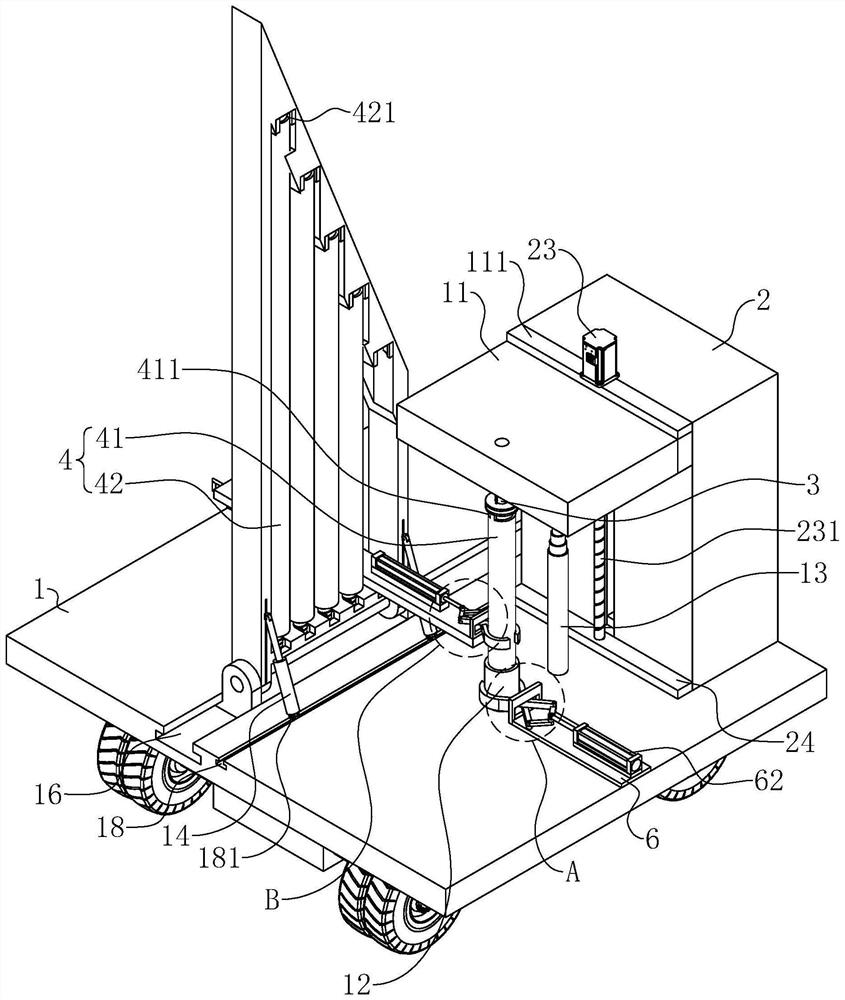

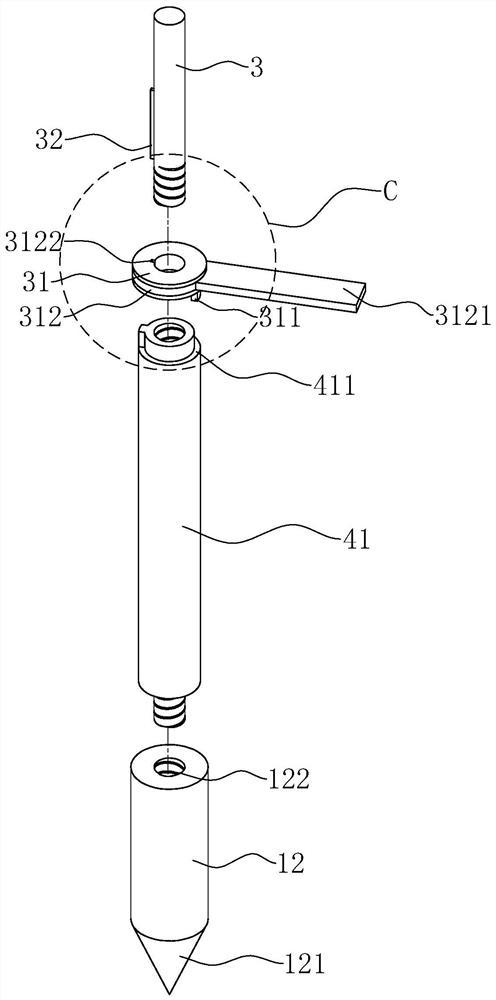

[0042] The embodiment of the present application discloses a down-the-hole drill for hydraulic engineering construction. refer to figure 1 and figure 2 The down-the-hole drill for water conservancy construction includes a cuboid base 1, the upper surface of the base 1 is vertically fixed with an adjustment frame 2, the adjustment frame 2 is slidably connected with a rotary mechanism 11, and the lower surface of the rotary mechanism 11 is fixed with a drill. The rod 3, the drill rod 3 is perpendicular to the upper surface of the base 1, the bottom end of the drill rod 3 is connected with a coaxial impactor 12, and the bottom end of the impactor 12 is fixed with a drill bit 121. During the working process, the rotary mechanism 11 drives the drill rod 3 to rotate, and the drill rod 3 drives the hammer 12 to drive the drill bit 121 to rotate, while the rotary mechanism 11 slides alon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com