Highway bridge crack repairing method

A technology for repairing cracks and highway bridges. It is applied in bridge maintenance, bridges, and bridge construction. It can solve problems such as poor repairing effect, and achieve the effect of improving enrichment effect, improving efficiency and improving repairing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

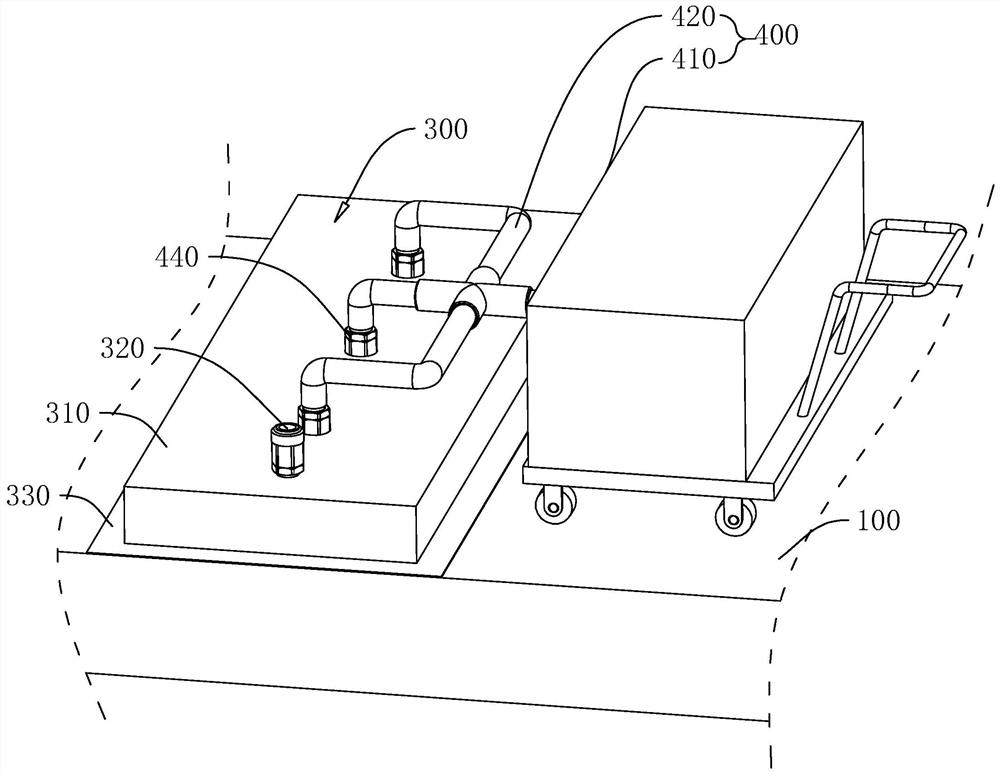

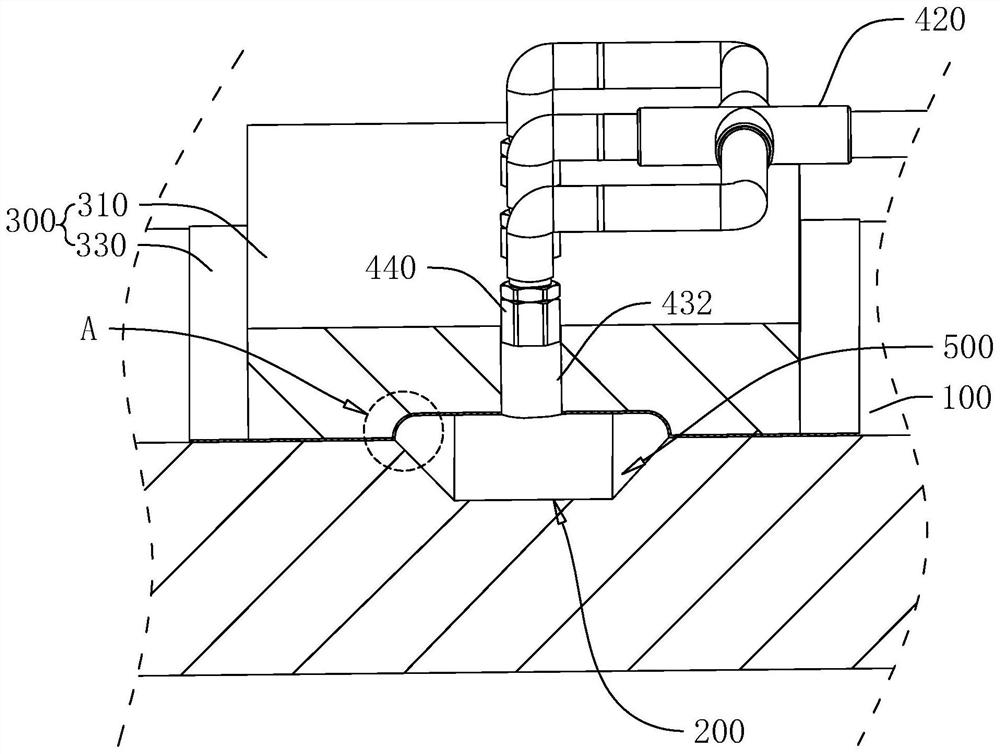

[0033] The following is attached Figure 1-3 The application is described in further detail.

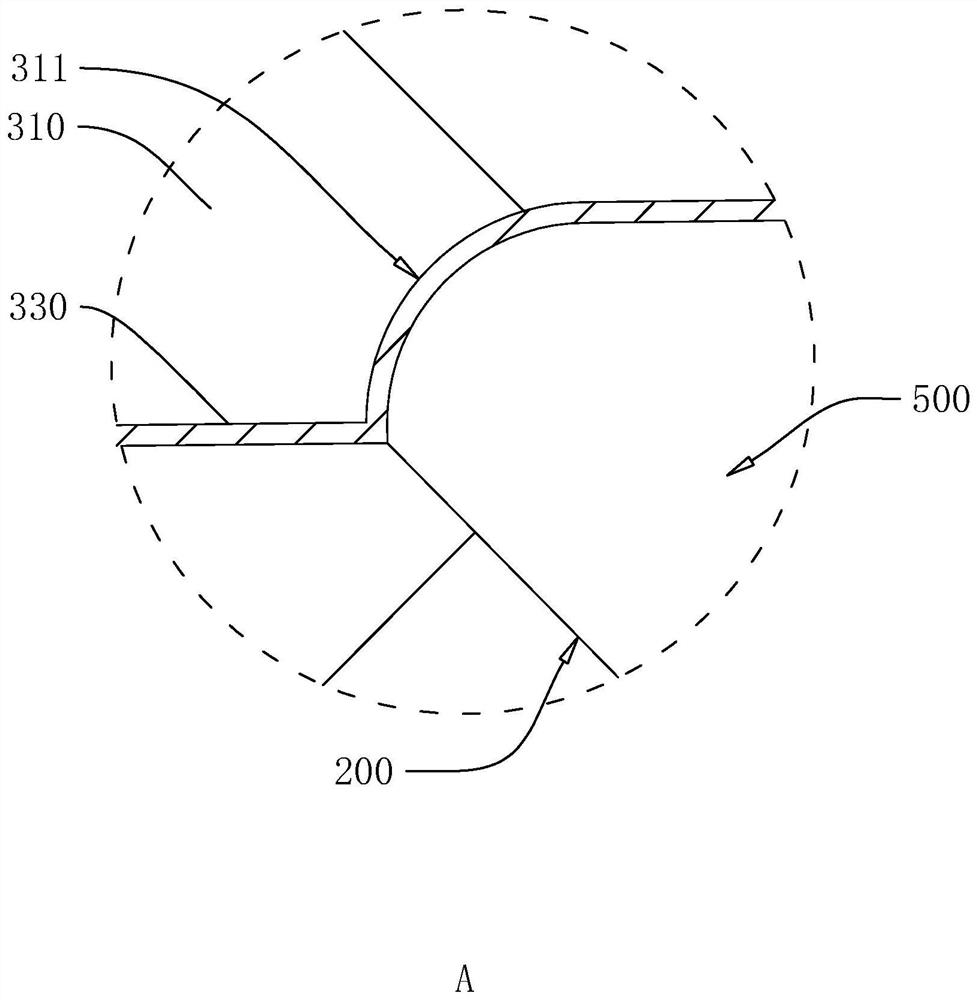

[0034] The embodiment of the present application discloses a method for repairing cracks in highway bridges, referring to figure 1 and figure 2 , including step S1, cutting: cut the roads on both sides of the crack along the length direction of the crack by a road surface cutting machine, and adjust the cutting angle so that the angle between the depth direction of the cutting seam formed during cutting and the good road surface 100 Less than 90°, the included angle is 45° in this embodiment;

[0035] Step S2, trimming; use a shovel to remove the solid between the two cutting seams to form the connecting ditch 200, and keep the side wall and bottom wall of the connecting ditch 200 flat, and the cross section of the connecting ditch 200 along the direction perpendicular to its length is trapezoidal. The arrangement of the connecting ditch 200 facilitates pouring asphalt into it l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com